jackhuang5919@gmail.com

Article

Supply Chain Risks When Sourcing Engineered Diesel Engines

This article examines supply chain risks when sourcing engineered diesel engines — focusing on the Isuzu D1703 Diesel Engine. It explains key vulnerabilities, practical mitigation strategies, a procurement checklist, brand advantages of Isuzu D1703, and answers common buyer questions to help procurement managers and equipment owners make informed decisions.

2025-12-26

Maintenance Strategies for Isuzu D1703 Engine Assemblies

Comprehensive maintenance strategies for the Isuzu D1703 engineered diesel engine assembly used in excavators and heavy machinery. Covers preventive schedules, condition-based monitoring, fuel and lubrication best practices, cooling and air intake care, parts replacement strategy, ROI of proper maintenance, and brand advantages—plus FAQs and authoritative references.

2025-12-25

Performance Under Load: Isuzu D1703 Engineered Diesel Review

An in-depth review of the Isuzu D1703 engineered diesel for heavy machinery. Covers design, performance under load, durability, fuel efficiency, integration for excavators, a comparison with typical rivals, business case, FAQs and authoritative references.

2025-12-25

Compatibility Checklist for Isuzu D1703 in Heavy Machinery

A practical, step-by-step compatibility checklist to assess integration of the Isuzu D1703 engineered diesel for excavators and heavy machinery. Covers mechanical fit, power and torque matching, cooling, fuel systems, emissions, electrical integration, serviceability, and procurement considerations with actionable checks and FAQs.

2025-12-24

Total Cost of Ownership: Engineered Diesel Isuzu D1703

This article evaluates the total cost of ownership (TCO) for the Isuzu D1703 engineered diesel engine for heavy machinery. It explains how engineered diesel design, fuel efficiency, maintenance practices, parts availability, and brand support reduce long-term operating costs and improve ROI for excavators and construction equipment.

2025-12-24

Procurement Guide: Specifying Isuzu D1703 Engine Assemblies

A comprehensive procurement guide for specifying Isuzu D1703 diesel engine assemblies for heavy machinery. Covers engineered diesel advantages, technical specification checklist, compatibility, procurement best practices, inspection criteria, cost-of-ownership comparison, brand strengths, FAQs and supplier selection tips to ensure reliable, efficient, and compliant engine performance.

2025-12-23

Engineered Diesel Advantages: Why Isuzu D1703 Fits Heavy Fleets

Engineered diesel solutions like the Isuzu D1703 Diesel Engine deliver the durability, fuel efficiency, and serviceability heavy fleets need. This article explains technical advantages, fleet benefits, maintenance tips, and why the Isuzu brand is a reliable choice for excavators and heavy machinery.

2025-12-23

Maintenance Contracts vs Parts Replacement: Procurement Considerations

This article compares maintenance contracts and parts replacement strategies for excavator hydraulic systems, focusing on procurement considerations for the 336D Excavator Hydraulic Pump. It covers cost, downtime, technical compatibility, OEM vs aftermarket choices, risk management, procurement checklists, and FAQs to help fleet managers and procurement teams decide the best approach.

2025-12-22

Warranty, Certifications and Quality Standards for Heavy Duty Pumps

A comprehensive guide to warranties, certifications, and quality standards for heavy duty hydraulic pumps, focused on the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement. Explains what warranties cover, key industry certifications and tests, contamination and maintenance standards, OEM vs aftermarket differences, and how to evaluate and choose a reliable hydraulic hydraulic pump. Includes FAQs, comparison table, authoritative references, and CTA to view product or contact sales.

2025-12-22

Supply Chain Risks and Lead Time Strategies for Pump Procurement

Practical, experience-driven guidance to identify and mitigate supply chain risks and shorten lead times when procuring hydraulic pumps — including OEM and aftermarket options for the 336D Excavator Hydraulic Pump.

2025-12-21

Inspection & Testing Protocols for New Excavator Hydraulic Pumps

Comprehensive, step-by-step inspection and testing protocols for new excavator hydraulic pumps — including pre-installation checks, bench testing, contamination control, acceptance criteria and troubleshooting — tailored for the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement.

2025-12-21

Sourcing Strategy: Reliable Suppliers for Hydraulic Hydraulic Pump Parts

A practical sourcing guide to finding reliable suppliers for hydraulic hydraulic pump parts, focusing on the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement. Covers OEM vs aftermarket tradeoffs, supplier evaluation, quality tests, logistics, cost control, brand advantages, and FAQs to help procurement and maintenance teams make confident buying decisions.

2025-12-20

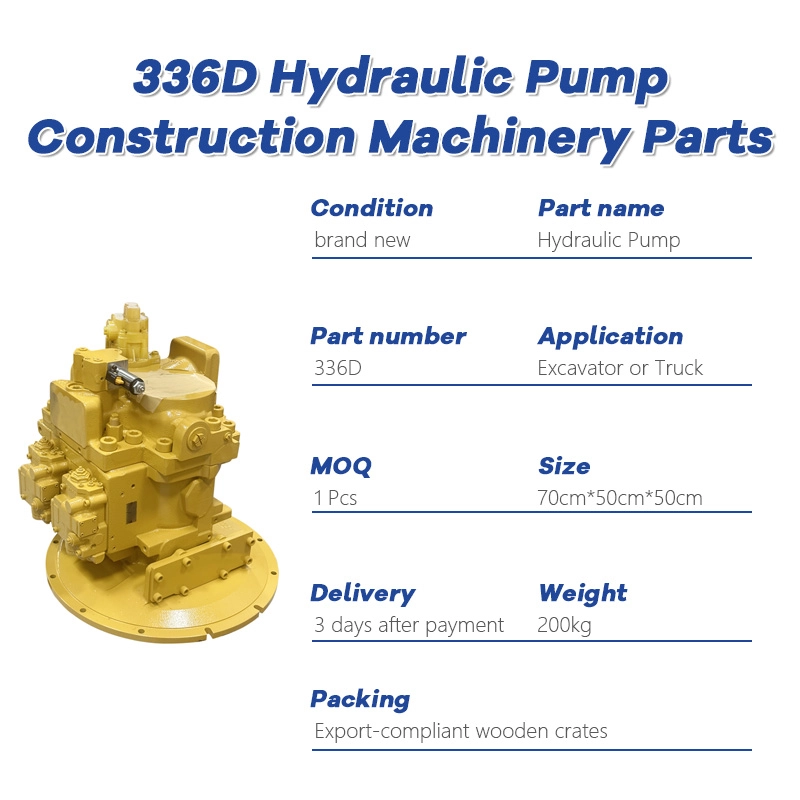

Compatibility Matrix: 336D Pump Fitment and Performance Factors

A practical guide to fitment and performance of the 336D Excavator Hydraulic Pump. Learn mechanical compatibility, hydraulic performance parameters, OEM vs aftermarket trade-offs, installation best practices, troubleshooting, maintenance tips, and how the Heavy Duty CAT Replacement pump ensures reliable operation.

2025-12-20

Total Cost of Ownership: Excavator Hydraulic Pump for Fleet Managers

A practical guide for fleet managers to calculate and minimize the total cost of ownership (TCO) of excavator hydraulic pumps, focusing on the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement and comparisons between OEM and aftermarket options.

2025-12-19

How Procurement Teams Evaluate Heavy Duty CAT Hydraulic Pumps

A practical procurement guide for evaluating heavy-duty CAT hydraulic pumps — including the CAT 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement. Covers technical criteria, testing, OEM vs aftermarket trade-offs, procurement checklists, cost-of-ownership comparisons, and FAQs to help purchasing teams make confident, E‑E‑A‑T–aligned decisions.

2025-12-19

Spec Checklist for 336D Excavator Hydraulic Pump Replacements

Comprehensive spec checklist and buying guide for 336D excavator hydraulic pump replacements. Covers compatibility, flow, pressure, mounting, OEM vs aftermarket comparison, installation tips, testing, maintenance, warranty and procurement guidance to ensure reliable performance for your CAT 336D hydraulic pump replacement.

2025-12-18

Buyer's Guide: Choosing a Hydraulic Hydraulic Pump for Excavators

This comprehensive buyer's guide explains how to choose the right hydraulic hydraulic pump for excavators, with focused guidance for selecting a replacement for the CAT 336D. It covers pump types, compatibility, performance specs, OEM vs aftermarket comparison, installation and maintenance tips, troubleshooting, and FAQs to help owners and technicians make informed purchase decisions.

2025-12-18

How suppliers ensure authenticity of engine assemblies

This comprehensive guide explains how suppliers verify the authenticity of engine assemblies — from documentation, serialization and supply-chain controls to physical inspection and laboratory testing — with specific guidance for the ZAX870-5G 6WG1 Diesel Engine used in Hitachi excavators. Practical buyer checklists, a comparison table of authentic vs counterfeit markers, FAQs and authoritative reference links are included to help procurement, service teams and fleet managers reduce risk and secure reliable performance.

2025-12-12

Warranty and service considerations for engine assemblies

A practical, expert guide to warranty terms, preventive maintenance, service contracts and best practices for engine assemblies, focusing on the ZAX870-5G 6WG1 Direct Injection Diesel Engine for Hitachi excavators. Learn how to protect warranty coverage, choose authorized service providers, manage claims, and optimize lifecycle costs.

2025-12-12

Compatibility checklist for ZAX870-5G 6WG1 engine assemblies

A comprehensive compatibility checklist for ZAX870-5G 6WG1 engine assemblies. This guide explains physical, mechanical, electrical, and emissions compatibility points, installation checks, testing procedures, common pitfalls, and recommended parts and practices for replacing or installing the ZAX870-5G 6WG1 Direct Injection Diesel Engine in Hitachi excavators.

2025-12-12

Recommended for you

Why Your Hydraulic Pump is Failing: 10 Red Flags You Can't Ignore (2026 Guide)

The Strategic Procurement of High-Performance Excavator Parts: A Comprehensive Guide to Minimizing Fleet Downtime

The Future of Engineered Diesel: Innovations Beyond 2026 for Peak Performance

Ultimate Guide to Hydraulic Pumps for 2026: Types & Trends