jackhuang5919@gmail.com

Procurement Risk Assessment for Large Diesel Engine Orders

- Procurement Risk Assessment for Large Diesel Engine Orders

- Why choosing the best diesel engine matters in large orders

- Product Introduction — SY550 6WG1 Diesel Engine

- Risk Category: Technical and Performance Risk (best diesel engine)

- Risk Category: Supplier and Reputation Risk (best diesel engine)

- Logistics, Delivery & Lead-time Risk

- Quality Assurance & Inspection Protocols (best diesel engine)

- Financial Risk and Payment Terms

- Warranty, After-sales Support, and Spare Parts Availability

- Regulatory and Emissions Compliance Risk

- Operational & Maintenance Risk: Lifecycle Cost Assessment (best diesel engine)

- Comparative Table: How candidates stack up (qualitative)

- Acceptance Testing and Commissioning Protocols

- Contract Clauses to Minimize Procurement Risk (best diesel engine)

- Checklist: Pre-award and Post-award Actions

- Case Study: Assessing SY550 6WG1 for a Fleet Procurement

- Brand and Product Advantages: Why SY550 6WG1 stands out

- Frequently Asked Questions (FAQ)

- Q1: How do I verify the SY550 6WG1 engine is the best choice for my operating conditions?

- Q2: What is the recommended inspection regime for large diesel engine deliveries?

- Q3: How long should I require parts availability and warranty coverage?

- Q4: How can I protect my purchase from supplier delivery failures?

- Q5: Are emissions certifications transferable across countries?

- Contact & View Product

- Authoritative References and Further Reading

Procurement Risk Assessment for Large Diesel Engine Orders

Why choosing the best diesel engine matters in large orders

When procuring dozens or hundreds of diesel engines for heavy equipment fleets, the purchase decision carries long-term operational, financial, and safety consequences. Buyers need to prioritize reliability, lifecycle cost, parts availability, compliance, and serviceability — not just initial price. The right selection can avoid costly downtime, warranty disputes, and regulatory issues. In this article we evaluate procurement risks for large diesel engine orders and show how a robust assessment process helps you secure the best diesel engine for heavy-duty excavators such as the SANY SY550. We also introduce the product: When Power Meets Precision – SY550 6WG1 Diesel Engine at Work! and explain how to assess it during procurement. Risk-controlled sourcing enables accurate financial modeling, leading to clear ROI calculations: when power meets precision with SY550 6WG1.

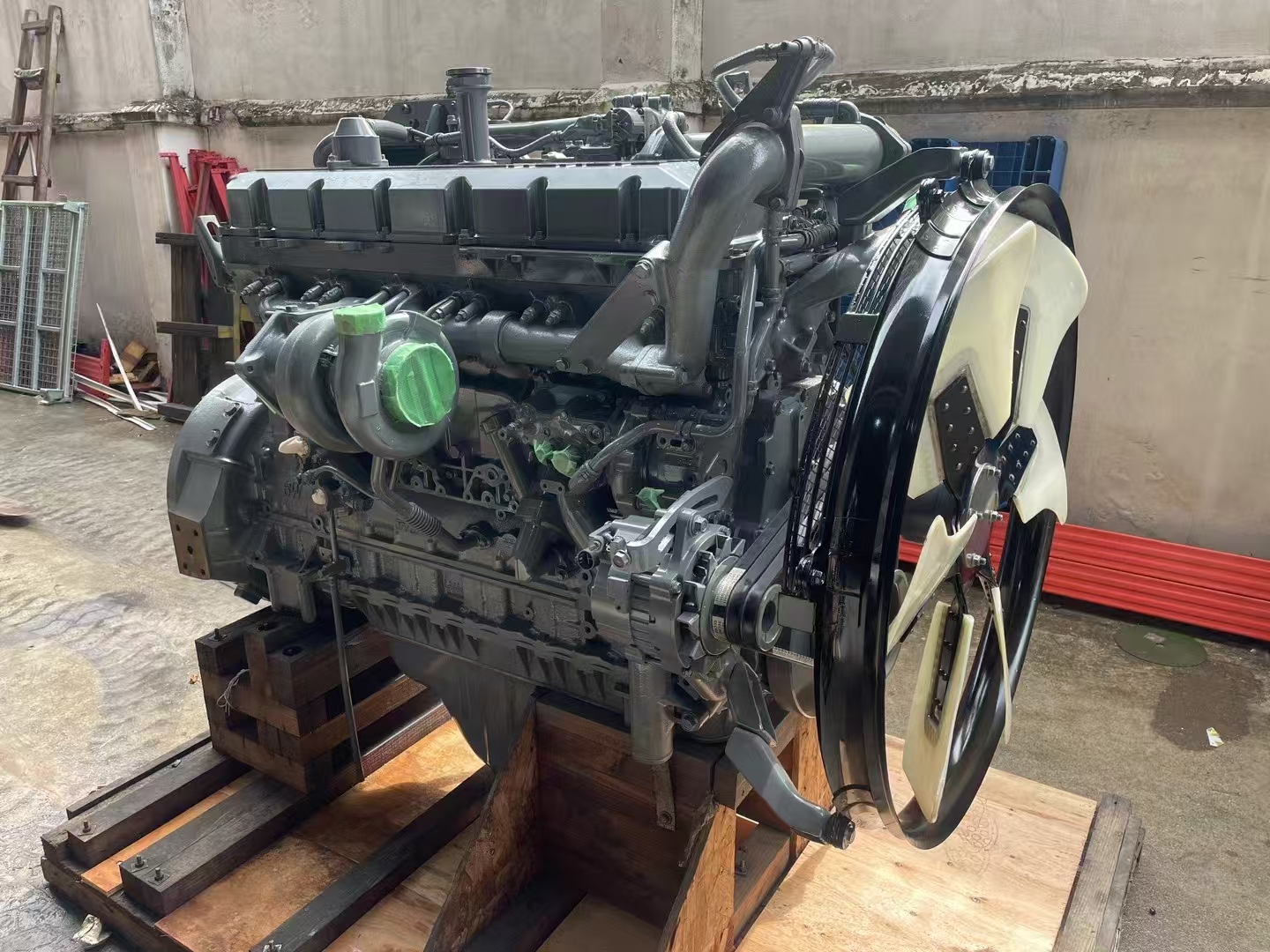

Product Introduction — SY550 6WG1 Diesel Engine

The SY550 6WG1 diesel engine is a high-performance power unit specially designed for heavy-duty excavators such as the SANY SY550. Developed with ISUZU technology, the 6WG1 engine delivers exceptional power, efficiency, and durability — making it one of the most reliable engines in the construction machinery industry.

Risk Category: Technical and Performance Risk (best diesel engine)

Technical risk is the probability that the engine will not meet performance or compatibility requirements. For heavy machines, that can mean inadequate torque curves, poor fuel consumption under load, or cooling-system mismatch. To reduce technical risk:

- Specify performance requirements: continuous power, peak torque, fuel efficiency under rated load, altitude and temperature range.

- Request OEM test reports and engine maps for the exact model and configuration; confirm that data is for the same tunings you will receive.

- Require FAT (Factory Acceptance Test) data and witness testing (or video documentation) for critical parameters.

- Verify compatibility with vehicle/generator control modules and emissions aftertreatment (if applicable).

Embedding best diesel engine into your vendor requirements means you explicitly list the technical and performance metrics you expect from engines in the procurement contract and scoring matrix.

Risk Category: Supplier and Reputation Risk (best diesel engine)

Large orders increase exposure to supplier-related issues: production delays, quality control failures, or business continuity problems. Mitigation steps:

- Supplier due diligence: review manufacturers' financials, production capacity, quality certifications (ISO 9001), and historical performance on similar large projects.

- Reference checks: request references for projects with similar volume and scope. Visit an installed-site if possible.

- Ownership of IP and supply chain transparency: confirm the origin of critical components (e.g., turbochargers, injectors, ECU) and second-source options.

Choosing a recognized manufacturer or authorized OEM partner is a common way to source the best diesel engine while minimizing supplier risk.

Logistics, Delivery & Lead-time Risk

Large engine orders intensify logistical complexity. Delays can stall entire projects. Key controls include:

- Firm lead-time commitments in the contract and liquidated damages for missed milestones.

- Staggered deliveries: phase shipments to match installation capacity and spare parts storage rules.

- Customs and export controls: confirm export licenses, certificates of origin, and compliance with local import rules.

- Packaging and transport specifications to protect engines during long multimodal transit.

Quality Assurance & Inspection Protocols (best diesel engine)

Quality inspection is essential to ensure engines match specifications and are free of manufacturing defects. Best practices:

- Define acceptance criteria and inspection checklists in the purchase order (visual, dimensional, functional tests, serial number controls).

- Mandate FAT and SAT (Site Acceptance Test) procedures with pass/fail criteria.

- Use third-party inspection agents (e.g., Lloyd’s, Bureau Veritas) for impartial inspections on large orders.

- Require traceable material and batch documentation for wear-critical parts (e.g., bearings, pistons).

Quality gates reduce the risk of receiving substandard or non-conforming engines and help ensure you're getting the best diesel engine for your application.

Financial Risk and Payment Terms

Large purchases tie up capital and expose buyers to currency and credit risk. Mitigations:

- Use staged payments tied to verified milestones (prototype, FAT, shipment, commissioning).

- Consider letters of credit or bank guarantees to protect prepayments.

- Hedge currency exposure when purchasing from foreign suppliers.

- Include warranty retention or escrow arrangements to secure post-delivery obligations.

Warranty, After-sales Support, and Spare Parts Availability

Downtime costs often outweigh purchase price. Ensure vendor commitments cover:

- Clear warranty terms (duration, coverage, exclusions, on-site vs. shop repairs).

- Guaranteed spare parts availability and lead times for critical items for a defined period (e.g., 5–10 years).

- Local service network or authorized service partners to speed repairs.

- Remote diagnostics and software support for modern ECU-equipped engines.

Regulatory and Emissions Compliance Risk

Engines must meet emissions and noise regulations in the operating jurisdiction. Steps:

- Verify engine certification for the target market (e.g., Stage IV / Tier 4 interim / Tier 3 where applicable).

- Confirm emissions control system compatibility if operating in restricted zones.

- Retain documentation for compliance audits (type-approval certificates, test reports).

Operational & Maintenance Risk: Lifecycle Cost Assessment (best diesel engine)

Lifecycle cost (LCC) is broader than purchase price and includes fuel, maintenance, parts, and residual values. To quantify LCC:

- Model fuel consumption across duty cycles, using OEM fuel maps and your operational hours.

- Estimate preventive-maintenance schedules and average repair parts consumption.

- Include downtime cost per hour to convert reliability metrics into monetary risk.

Use LCC scoring when comparing candidates so you select the true best diesel engine by total cost rather than lowest initial price.

Comparative Table: How candidates stack up (qualitative)

The following table is a template comparison for evaluation. Populate with verified supplier data during procurement.

| Criteria | SY550 6WG1 (ISUZU-based) | Competitor A | Competitor B |

|---|---|---|---|

| Rated Power & Torque | High, optimized for heavy excavator duty | Comparable | Lower peak torque |

| Fuel Efficiency | Efficient under full load | Moderate | Variable |

| Parts Availability | Good — ISUZU technology backbone | Depends on OEM network | Limited local support |

| After-sales Service | Authorized SANY/ISUZU channels | Regional partners | Third-party service required |

| Certifications | Market-dependent (check regional type approval) | Varies | Varies |

Acceptance Testing and Commissioning Protocols

Acceptance testing must be defined in the contract with clear pass/fail criteria. Typical steps:

- Factory Acceptance Test (FAT): functional engine run, emissions check, leak test, and documentation review.

- Pre-shipment inspection: verify serial numbers, packaging, and certificates.

- Site Acceptance Test (SAT): engine under machine loads, thermal behavior, control integration, and vibration checks.

- Final sign-off and release of final payment upon satisfactory SAT.

Contract Clauses to Minimize Procurement Risk (best diesel engine)

Contracts should clearly allocate risk and remedies. Include:

- Detailed technical specification attachment with tolerances.

- Delivery schedule, milestone payments, and liquidated damages.

- Warranty and spare parts obligations, with defined response times.

- Inspection rights and third-party verification clauses.

- Dispute resolution mechanism and force majeure definitions.

Checklist: Pre-award and Post-award Actions

Pre-award:

- Complete technical scorecard and supplier risk assessment.

- Validate references and factory capabilities.

- Confirm logistics plan and customs readiness.

Post-award:

- Schedule FAT and inspection windows.

- Lock in spare parts agreements and service contracts.

- Implement commissioning and acceptance plans.

Case Study: Assessing SY550 6WG1 for a Fleet Procurement

Scenario: A contractor seeks 30 engines for SANY SY550 excavators. Applying the above approach:

- Technical: Confirm 6WG1 maps for intended duty and altitude; run sample engine under duty cycle in OEM lab.

- Supplier: Review SANY and ISUZU joint production lines, request proof of capacity for 30 units within project timeline.

- Quality: Require FAT for first 3 units and third-party inspection for remainder.

- Commercial: Stage payments 30/40/30% linked to sample approval, shipment, and SAT success; include 24-month warranty and 5-year parts availability guarantee.

- Operational: Secure local authorized service partner and parts depot to minimize mean time to repair.

Result: With these mitigations the procurement team significantly reduced technical and delivery risk while ensuring lifecycle support — a practical path to secure engines that can be considered among the best diesel engine choices for the fleet.

Brand and Product Advantages: Why SY550 6WG1 stands out

Combining ISUZU engine technology with SANY application engineering gives the SY550 6WG1 several practical advantages for heavy excavators:

- Purpose-built calibration for heavy-duty excavation — improved torque delivery under high load.

- Proven component supply chain and established parts support through ISUZU-derived architecture.

- Strong OEM integration between engine and machine systems reducing ECU and hydraulic interface risks.

- Manufacturer-backed warranty and global service network from SANY and ISUZU partnerships.

When an organization wants reliable performance, low total cost of ownership, and assured parts support, the SY550 6WG1 is a competitive candidate for buyers seeking the best diesel engine for large excavators.

Frequently Asked Questions (FAQ)

Q1: How do I verify the SY550 6WG1 engine is the best choice for my operating conditions?

A1: Define your duty cycle, operating temperature range, altitude, fuel quality, and emissions requirements. Request the engine’s performance maps, FAT data, and real-world fuel consumption records for similar jobs. Compare lifecycle cost estimates (fuel + maintenance + downtime) across candidates.

Q2: What is the recommended inspection regime for large diesel engine deliveries?

A2: Insist on Factory Acceptance Tests for initial units, random pre-shipment inspections, and site acceptance tests. Use a third-party inspector for impartial reports on critical lots.

Q3: How long should I require parts availability and warranty coverage?

A3: For heavy equipment, require parts availability for at least 5 years and a warranty of 12–36 months depending on usage intensity. For large fleets or critical operations, negotiate longer spare-parts guarantees with penalties for non-availability.

Q4: How can I protect my purchase from supplier delivery failures?

A4: Use milestone-based payments, include liquidated damages for missed delivery windows, require performance bonds or bank guarantees, and maintain alternative supplier options for critical parts.

Q5: Are emissions certifications transferable across countries?

A5: No. Emissions approvals are jurisdiction-specific. Always verify that the engine version you purchase holds the necessary type-approval or certificates for your operating country or region.

Contact & View Product

To discuss procurement, request FAT documentation, or schedule an inspection for When Power Meets Precision – SY550 6WG1 Diesel Engine at Work!, contact our sales team or view the product page. Our procurement specialists can provide customized LCC models, inspection checklists, and contract templates tailored to your project.

Contact: procurement@example.com | +86 123 4567 890

View product details and request a quote

Authoritative References and Further Reading

- Diesel engine – Wikipedia: https://en.wikipedia.org/wiki/Diesel_engine

- SANY Global – Official site: https://www.sanyglobal.com/

- ISUZU Engines / Commercial Vehicle Info: https://www.isuzucv.com/

- ISO — International Organization for Standardization (quality standards): https://www.iso.org/

- Industry inspection services (example): Bureau Veritas — https://group.bureauveritas.com/

References above provide background on diesel engine fundamentals, OEM information, standards, and third-party inspection services. Use them to validate specifications and certifications cited by suppliers.

Supply Chain Risks When Sourcing Engineered Diesel Engines

Signs of Hydraulic Pump Failure Under Load: Detection, Diagnosis & Fixes

How Hydraulic Pump Efficiency Impacts Excavator Performance 2026

Hydraulic Pump Performance Metrics to Track in 2026

FAQ

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -