jackhuang5919@gmail.com

Performance Benchmarks: Comparing Top Excavator Diesel Engines

- Performance Benchmarks: Comparing Top Excavator Diesel Engines

- Why selecting the best diesel engine matters for excavator performance

- Product Introduction — When Power Meets Precision – SY550 6WG1 Diesel Engine at Work!

- Key performance metrics to compare excavator diesel engines

- Benchmark methodology — how we compare engines

- Comparative performance table — SY550 6WG1 and peer engines

- Interpreting the table — practical takeaways

- Why the SY550 6WG1 can be the best diesel engine for heavy excavation jobs

- How fuel economy and emissions affect selection of the best diesel engine

- Selection checklist — choose the best diesel engine for your fleet

- Brand advantages — SANY and ISUZU collaboration summarized

- Practical field tips when deploying large excavator engines

- FAQ — Performance Benchmarks & SY550 6WG1

- Q: Is the SY550 6WG1 the best diesel engine for all excavator tasks?

- Q: How does fuel consumption of the SY550 6WG1 compare to competitors?

- Q: What maintenance should I expect for a 6WG1-style heavy diesel engine?

- Q: Are ISUZU-derived engines easier to service globally?

- Need help choosing or testing the best diesel engine for your fleet?

- Authoritative references and further reading

Performance Benchmarks: Comparing Top Excavator Diesel Engines

Why selecting the best diesel engine matters for excavator performance

Choosing the best diesel engine for an excavator is more than selecting peak power numbers. For heavy machines, engine choice determines fuel consumption, torque at working RPMs, machine uptime, maintenance cost and emissions compliance. Contractors and fleet managers evaluate engines on operational metrics (fuel economy and usable torque), lifecycle cost (maintenance, parts availability), and real-world durability under arduous site conditions. This article benchmarks top excavator diesel engines with a practical lens—what matters most on the jobsite—then focuses on the SY550 6WG1 diesel engine and where it excels.

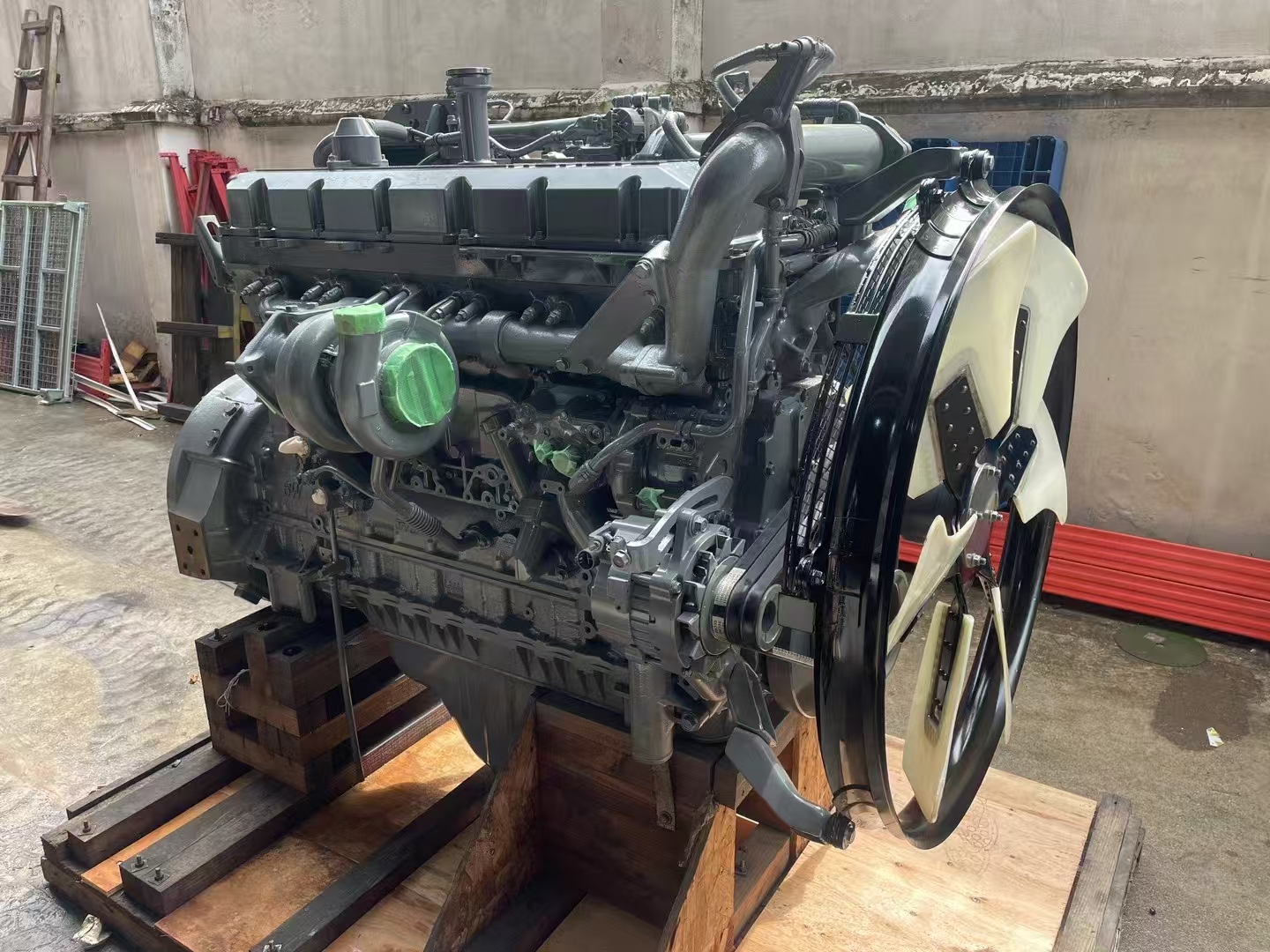

Product Introduction — When Power Meets Precision – SY550 6WG1 Diesel Engine at Work!

The SY550 6WG1 diesel engine is a high-performance power unit specially designed for heavy-duty excavators such as the SANY SY550.

Developed with ISUZU technology, the 6WG1 engine delivers exceptional power, efficiency, and durability — making it one of the most reliable engines in the construction machinery industry.

Key performance metrics to compare excavator diesel engines

When benchmarking engines, use standardized and job-focused metrics. Each metric below is a decision driver for selecting the best diesel engine for your application:

- Rated power (kW / hp): Maximum continuous power available; influences lifting and travel speeds.

- Peak torque and torque curve: Torque at low RPM affects digging force and controllability under load.

- Specific fuel consumption (SFC): Measured in g/kWh or l/h under load—critical for operating cost.

- Displacement and thermal efficiency: Often correlates with durability and fuel use characteristics.

- Emissions compliance: Tier/Stage standards impact aftertreatment needs and fuel types.

- Service interval and ease of maintenance: Downtime and parts logistics determine total cost of ownership.

- Reliability and parts network: Field-proven designs and global support reduce downtime risks.

Benchmark methodology — how we compare engines

This benchmark uses manufacturer published ratings, industry test reports and operator feedback to compare engines on real-world performance rather than theoretical maximums. Where exact numeric parity is difficult (due to differing test cycles), the comparison uses normalized indicators: power class, relative fuel economy ranges, expected maintenance intervals and support network strength. For decision-makers we focus on lifecycle cost, uptime and application fit—factors that determine whether an engine is the best diesel engine for a specific fleet or job type.

Comparative performance table — SY550 6WG1 and peer engines

The table below compares the SY550 6WG1 (ISUZU-based) with several leading heavy-excavator power units in the same class. Numbers are illustrative ranges based on manufacturer classes and industry reports. For exact model-year specifications consult the OEM datasheets linked in the references.

| Engine (typical application) | Power class (kW) | Usable torque behavior | Typical SFC (g/kWh or l/h) | Service interval (hours) | Notes (strengths) |

|---|---|---|---|---|---|

| SY550 6WG1 (SANY SY550) — ISUZU technology | ~300–350 kW class | Strong low-end torque, stable under heavy load | Competitive for class; optimized for duty cycles | 500–1,000+ (depends on maintenance plan) | Durability, efficient torque delivery, good OEM integration |

| Caterpillar C13/C15 range (large excavators) | 300–350 kW class | High torque, broad torque curve | Industry-standard; historically strong SFC | 500–1,000+ | Proven reliability, global parts network, robust support |

| Komatsu SAA6 / SAA6D series | 250–350 kW class (varies by model) | Good mid-range torque, suited to continuous digging | Competitive; optimized for construction cycles | 500–1,000+ | Well-integrated with Komatsu machines, strong durability |

| Other OEM ISUZU-based heavy engines | 250–350 kW class | Dependable low-end torque | Similar to SY550 6WG1 in class | 500–1,000+ | Low-cost maintenance, proven heavy-duty roots |

Interpreting the table — practical takeaways

Table values show that multiple engines compete closely in raw power for the heavy-excavator class. The differentiators are torque delivery at working RPM, fuel efficiency under typical duty cycles, and real-world uptime tied to service networks. The SY550 6WG1 stands out where SANY's machine and powertrain are matched to achieve consistent torque delivery and simplified maintenance access—advantages that reduce operating costs over years in heavy applications.

Why the SY550 6WG1 can be the best diesel engine for heavy excavation jobs

Based on the ISUZU-derived design and SANY integration, the SY550 6WG1 offers several practical advantages that matter to fleet operators:

- Engine-machine integration: Engines tuned to the machine improve hydraulic performance, cab controllability and fuel use across typical excavation cycles.

- Torque-focused performance: For digging, trenching and loading the usable torque in the low-to-mid RPM band is more important than peak horsepower alone—an area where 6WG1 designs prioritize stable torque.

- Durability and proven technology: Development with ISUZU engineering practices emphasizes robust components and field-proven systems.

- Serviceability: Design that simplifies routine access points reduces downtime and lowers labor hours per service event.

- Total cost of ownership: When evaluated across fuel consumption, maintenance intervals and parts pricing, an optimized engine-machine package like SY550 6WG1 can deliver lower lifecycle cost in many deployments.

How fuel economy and emissions affect selection of the best diesel engine

Fuel is often the largest single operating expense for heavy excavators. When evaluating engines, compare:

- Real-duty SFC: Look for fuel consumption measured under representative working cycles, not just ISO-rated values.

- Aftertreatment impact: Emissions systems (DOC, DPF, SCR) can influence backpressure and service needs—evaluate schedules and consumables.

- Alternative fuels and retrofit potential: For some fleets, compatibility with low-sulfur diesel or renewable diesel is important.

Selection checklist — choose the best diesel engine for your fleet

To select the best diesel engine for your excavator fleet, use this practical checklist:

- Match engine class to application: heavy lifting and hard digging need high low-end torque; high-cycle loading may prioritize fuel economy.

- Request real-world fuel consumption data from OEMs or operators running the same machine in similar conditions.

- Verify local parts availability and authorized service centers—engine uptime depends on logistics.

- Confirm emissions compliance for your operating region (Stage/Tier) and evaluate aftertreatment maintenance cost.

- Compare warranty coverage and optional service packages that reduce unplanned downtime.

Brand advantages — SANY and ISUZU collaboration summarized

The partnership represented by the SY550 6WG1 blends SANY’s machine design expertise with ISUZU’s engine technology. This combination yields several concrete benefits:

- Optimized integration: Engine calibration matches SANY hydraulic and electronic control strategies for predictable, efficient performance.

- Proven componentry: ISUZU contributions build on a global heritage of durable diesel engines, while SANY applies this to excavator-specific needs.

- Global support: Combined brand reach and established dealer networks help secure parts and service in major markets.

For fleet buyers seeking the best diesel engine in heavy excavation applications, an engine that is optimized within the machine (not just a standalone spec sheet) often delivers the best long-term results.

Practical field tips when deploying large excavator engines

Operators can improve engine life and reduce costs by following these practices:

- Use OEM-recommended oil and filtration schedules; contaminants are a common cause of premature engine wear.

- Monitor operating patterns—limit prolonged idling and avoid unnecessary high-RPM operation.

- Maintain cooling systems and ensure clean air intake paths; overheated engines and dust ingestion accelerate failures.

- Keep a parts kit for high-wear items (filters, belts, common sensors) to reduce downtime between service calls.

FAQ — Performance Benchmarks & SY550 6WG1

Q: Is the SY550 6WG1 the best diesel engine for all excavator tasks?

A: No single engine is best for every scenario. The SY550 6WG1 is engineered for heavy-duty excavators and excels in tasks requiring sustained torque and durability. For light or high-cycle tasks, other engines optimized for fuel economy or lighter displacement may be more suitable.

Q: How does fuel consumption of the SY550 6WG1 compare to competitors?

A: Fuel consumption depends on duty cycle and machine tuning. In general, engines in this power class are competitive; the advantage comes from system-level optimization between engine and hydraulic systems. Ask OEMs for real-duty SFC figures measured under comparable cycles.

Q: What maintenance should I expect for a 6WG1-style heavy diesel engine?

A: Expect regular oil and filter changes, fuel system upkeep, aftertreatment service (if equipped), coolant system checks and periodic valve and injector inspections according to the OEM schedule. Proper maintenance extends life and protects resale value.

Q: Are ISUZU-derived engines easier to service globally?

A: ISUZU has a broad global footprint and long history in diesel engines, which generally makes parts and technical support easier to obtain. When paired with a major machine OEM like SANY, the combined dealer network typically enhances local serviceability.

Need help choosing or testing the best diesel engine for your fleet?

As comparisons scale to volume orders, it’s vital to address procurement risk assessment for large diesel engine orders early in the process.If you want to evaluate the SY550 6WG1 for a specific application or compare lifecycle costs with an existing fleet, contact our sales and technical team. We can provide detailed performance data, arrange machine demos, and tailor a maintenance plan to your operating environment.

Contact us to learn more about the SY550 6WG1, request a quote, or schedule an on-site evaluation.

Authoritative references and further reading

Below are authoritative sources referenced for engine fundamentals, emissions standards and OEM information:

- Diesel engine fundamentals — Wikipedia: https://en.wikipedia.org/wiki/Diesel_engine

- SANY Global — official OEM site and product resources: https://www.sanyglobal.com/

- ISUZU — company and engine information: https://www.isuzu.co.jp/world/

- U.S. EPA — emissions standards and diesel regulations: https://www.epa.gov/

- Caterpillar official: https://www.cat.com/

- Komatsu official: https://www.komatsu.com/

- Industry insights and equipment testing — Construction Equipment magazine: https://www.constructionequipment.com/

- International Organization for Standardization (ISO) — standards related to engines and emissions: https://www.iso.org/

Note: For machine- and model-year-specific specifications, consult the OEM datasheet and local dealer. The comparative ranges presented here are based on typical class performance and industry reporting; exact numbers vary by configuration, emissions equipment and regional tuning.

Installation Checklist for Doosan DX65 Main Hydraulic Pump

Troubleshooting engine assemblies: noise, smoke, and leaks

Where to Buy excavator engines in China

Best excavator hydraulic pump manufacturers and supplier brands

FAQ

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -