jackhuang5919@gmail.com

Fuel Efficiency Metrics: Selecting the Best Diesel Engine

- Fuel Efficiency Metrics: Selecting the Best Diesel Engine

- Why 'best diesel engine' depends on measurable fuel efficiency

- Key fuel-efficiency metrics and what they tell you

- How to measure and compare engines — practical guidance for buyers

- Product Introduction — When Power Meets Precision – SY550 6WG1 Diesel Engine at Work!

- Why the SY550 6WG1 is a strong candidate for 'best diesel engine' in heavy excavators

- Comparing fuel-efficiency metrics — a practical table

- Real-world tips to maximize fuel efficiency with any diesel engine

- Cost modeling: how small efficiency differences scale

- Maintenance and lifecycle considerations that affect long-term fuel efficiency

- Brand and product advantages: why choose the SY550 6WG1 for fuel-conscious buyers

- FAQ — Fuel Efficiency Metrics & the SY550 6WG1

- Contact & see the product

- Authoritative references

- Final note

Fuel Efficiency Metrics: Selecting the Best Diesel Engine

Why 'best diesel engine' depends on measurable fuel efficiency

When buyers search for the best diesel engine for heavy construction equipment, they usually mean the engine that delivers the optimal balance of power, fuel economy, reliability, and lifecycle cost under the expected duty cycle. Fuel efficiency is not a single number — it's a set of measurable metrics (BSFC, thermal efficiency, specific power, load-specific fuel consumption, and real-world fuel burn per operating hour) that together determine how cost-effective an engine will be over its service life. Understanding these metrics allows fleet managers and equipment buyers to choose engines that reduce total operating cost while meeting emissions and performance requirements. With efficiency benchmarks defined, deployment success depends on a smooth integration guide: installing SY550 6WG1 into existing fleets.

Key fuel-efficiency metrics and what they tell you

To evaluate which diesel engine is the best for your excavator or heavy machine, focus on these core metrics:

- Brake Specific Fuel Consumption (BSFC) — grams of fuel consumed per kilowatt-hour (g/kWh). Lower BSFC at the engine’s typical load means better thermal efficiency and lower fuel cost for the same power output.

- Power curve & torque band — engines that deliver peak torque across a broad RPM range allow machines to operate at lower engine speeds with similar hydraulic output, lowering fuel use.

- Fuel consumption at rated load (L/h or gal/h) — important for hourly operating cost estimates under typical loads.

- Specific power (kW per liter) & power density — higher specific power reduces engine weight and packaging constraints but must be balanced against fuel efficiency.

- Idle and low-load efficiency — many excavator applications spend time at partial loads; engines with good low-load efficiency avoid wasting fuel during these periods.

- Aftertreatment backpressure & parasitic losses — emissions hardware can add losses; engines designed to minimize these penalties retain better fuel efficiency in real-world conditions.

How to measure and compare engines — practical guidance for buyers

Manufacturers publish several figures, but true comparison requires consistent test conditions. Use standardized data (ISO 8178 test cycles where available) or validated field data. Key steps:

- Compare BSFC curves rather than single-point values — examine how BSFC changes across RPM/load relevant to your typical work.

- Request fuel consumption data for representative machine cycles (digging, swing, travel, idle) with the engine installed in the machine; installed and calibrated engines behave differently than bare-engine bench results.

- Include aftertreatment and accessories in parasitic loss estimates (air conditioning, hydraulics pumps, alternator).

- Consider lifecycle fuel cost: estimate fuel use over expected hours and multiply by local fuel price — small BSFC differences compound over thousands of hours.

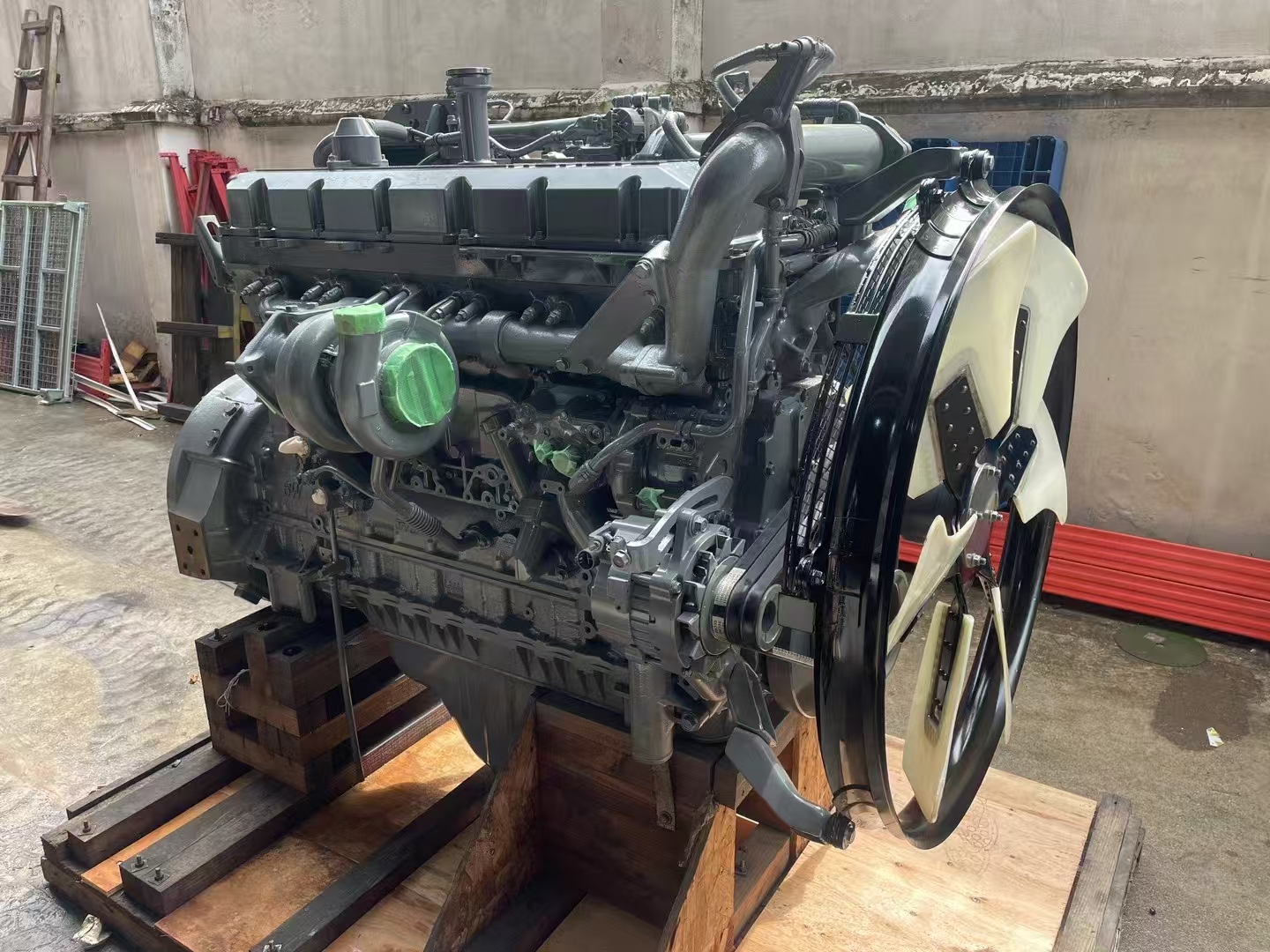

Product Introduction — When Power Meets Precision – SY550 6WG1 Diesel Engine at Work!

The SY550 6WG1 diesel engine is a high-performance power unit specially designed for heavy-duty excavators such as the SANY SY550.

Developed with ISUZU technology, the 6WG1 engine delivers exceptional power, efficiency, and durability — making it one of the most reliable engines in the construction machinery industry.

Why the SY550 6WG1 is a strong candidate for 'best diesel engine' in heavy excavators

The SY550 6WG1 combines proven ISUZU-engineering practices with application-specific calibrations for SANY’s heavy excavator platform. Key attributes that support fuel-efficiency objectives:

- Engine mapping tuned for working cycles: Calibrations optimized for dig/swing/load transitions reduce transient fuel spikes.

- Robust torque delivery: A broad torque band lets the machine operate efficiently at lower RPMs.

- Durability reduces efficiency degradation over life: Lower wear rates mean compression and injection timing remain closer to ideal for longer, preserving BSFC.

- Compatibility with modern aftertreatment: Efficient integration with DPF/SCR systems reduces backpressure penalties.

Comparing fuel-efficiency metrics — a practical table

The table below shows typical benchmark ranges for heavy-excavator diesel engines, how those benchmarks influence operating costs, and where a well-tuned engine like the SY550 6WG1 is positioned. Note: actual performance varies with configuration and duty cycle.

| Metric | Industry Typical Range | What to expect from a well-tuned unit (e.g., SY550 6WG1) | Why it matters |

|---|---|---|---|

| Brake Specific Fuel Consumption (BSFC) | ~180–220 g/kWh (varies by size/load) | Lower-to-mid of range when properly tuned and maintained | Directly affects fuel cost per unit of work |

| Fuel consumption at typical working load | 15–40 L/h (depending on machine size and cycle) | Optimized to minimize spikes during cycle transitions | Determines hourly operating cost |

| Specific power (kW/L) | 5–12 kW/L (higher for compact units) | Balanced for power density and fuel efficiency | Affects machine mass, packaging, and fuel burn under load |

| Idle & low-load consumption | Significant contributor in mixed cycles | Lower idle burn through management strategies (auto-idle) | Reduces wasted fuel when machine is waiting |

Real-world tips to maximize fuel efficiency with any diesel engine

Even the best diesel engine requires the right practices to deliver fuel savings in the field:

- Match the engine to the task: Oversized engines at low loads waste fuel; undersized engines work harder and burn more for the same output.

- Use correct gear/hydraulic settings: Modern excavators can be tuned (ECU, hydraulic flow settings) to optimize system-wide efficiency.

- Maintain regularly: Clean air filters, correct injection timing, fuel filters, and regular oil changes preserve BSFC and torque delivery.

- Monitor operating patterns: Telematics and fuel-flow meters reveal opportunities to reduce idle time and optimize work cycles.

- Train operators: Operator behavior (smooth throttle, minimizing unnecessary idle) has immediate effects on fuel use.

Cost modeling: how small efficiency differences scale

Because fuel is a major portion of operating cost, even a 3–5% improvement in BSFC compounds to large savings. Example model (simplified):

- Assume annual running hours: 2,000 h

- Average fuel consumption: 25 L/h

- Annual fuel use: 50,000 L

- Fuel price: $1.10/L

A 5% improvement in fuel efficiency saves 2,500 L/year = $2,750/year. Over a typical 8–10 year machine life the savings are substantial — and improvements stack with lower maintenance downtime and longer component life.

Maintenance and lifecycle considerations that affect long-term fuel efficiency

Fuel-efficiency numbers drift over time as engines accumulate hours. For best lifetime efficiency:

- Follow OEM scheduled maintenance and use recommended lubricants and fuels.

- Replace worn components (injectors, turbochargers) before they degrade performance significantly.

- Use engine diagnostics and telematics to detect issues early (e.g., injector drift, turbocharger inefficiency).

- Plan rebuilds or overhauls with attention to restoring original compression and injection parameters.

Brand and product advantages: why choose the SY550 6WG1 for fuel-conscious buyers

Synthesizing the discussion above, the SY550 6WG1 has attributes that align it with the 'best diesel engine' criteria for heavy excavators:

- Proven ISUZU engineering: Access to mature combustion and mechanical designs that keep BSFC competitive.

- Application-specific calibration: Tuned to the SY550 excavator’s duty cycle, reducing transient fuel penalties.

- Serviceability and parts support: Readily available parts and trained service reduce downtime and maintain fuel efficiency over life.

- Integration with emissions controls: Designed to work with aftertreatment with minimal parasitic loss.

FAQ — Fuel Efficiency Metrics & the SY550 6WG1

Q: What single metric should I look at when choosing the best diesel engine?

A: Don't rely on a single metric. BSFC is critical, but you must evaluate BSFC across the engine's operating band, installed fuel consumption in typical cycles, torque characteristics, and lifecycle maintenance costs.

Q: How often will I see fuel-efficiency degradation?

A: With proper maintenance, efficiency loss is slow. Neglected maintenance (dirty air filters, poor fuel quality, worn injectors) can cause appreciable BSFC deterioration within hundreds to a few thousand hours.

Q: Can telematics help me achieve 'best diesel engine' performance?

A: Yes. Telematics provide work-cycle data, idle time, and fuel-flow measurements that enable operator coaching and maintenance interventions that recover fuel savings.

Q: Is the SY550 6WG1 compliant with modern emissions while remaining fuel-efficient?

A: The SY550 6WG1, using ISUZU technology and proper aftertreatment, is designed to meet emissions requirements for its market while preserving fuel efficiency. Always verify local emissions certification for the specific engine configuration.

Q: How do I realistically compare manufacturer fuel numbers?

A: Ask for installed-machine fuel consumption tests or request ISO 8178 test-cycle results. Compare curves not points and confirm test conditions match your application.

Contact & see the product

To evaluate how the SY550 6WG1 performs in your specific application, contact our sales engineers for installed-machine fuel-consumption data, telematics sample reports, and lifecycle cost models. Email: sales@yourcompany.com or visit our product page and request a performance dossier.

Authoritative references

- Brake-specific fuel consumption — Wikipedia

- Diesel engine — Wikipedia

- ISO 8178 emissions and test cycles — Wikipedia

- U.S. EPA: Regulation of Nonroad Diesel Engines

- SAE International — engine testing and standards

Final note

Choosing the best diesel engine is a systems decision: engine thermodynamics, vehicle integration, operator practice, and maintenance collectively determine fuel efficiency and lifecycle cost. The SY550 6WG1, developed with ISUZU technology and tuned for heavy excavator duty, is engineered to be a competitive option for buyers prioritizing fuel economy, durability, and total cost of ownership. Contact us to get machine-specific data and a custom fuel-cost analysis tailored to your operation.

Procurement Guide: Specifying Isuzu D1703 Engine Assemblies

Best Ways to Extend Hydraulic Pump Lifespan in Excavators 2026

The B2B Buyer’s Guide to electric hydraulic pressure pump

Where to Buy engine assembly

FAQ

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -