jackhuang5919@gmail.com

The Future of Engineered Diesel: Innovations Beyond 2026 for Peak Performance

A comprehensive guide to engineered diesel, covering advanced fuel chemistry, next-gen engine systems, and sustainability trends beyond 2026. Learn about HVO, thermal efficiency, and expert maintenance tips.

- What is Engineered Diesel?

- Key Takeaways: Engineered Diesel at a Glance

- The Evolution of Diesel Engineering: From Rudolf Diesel to Modern Marvels

- Engineering Diesel Fuels: Beyond the Basic Hydrocarbon

- Precision Engineering in Diesel Engines: Components & Systems

- The Future Landscape: Engineered Diesel Innovations Beyond 2026

- Why Engineered Diesel Matters: Benefits Across Industries

- Expert Tips for Maximizing Engineered Diesel Performance & Lifespan

- Common Misconceptions About Modern Engineered Diesel

- The Road Ahead: Challenges and Opportunities for Engineered Diesel

- Conclusion

- FAQ

- What is the main purpose of engineering diesel fuel?

- How do engineered diesel engines achieve better fuel efficiency?

- Are renewable diesel fuels considered "engineered diesel"?

- What role does AI play in the future of engineered diesel technology?

- How do modern emissions control systems in engineered diesel engines work?

- What are the advantages of common rail fuel injection in engineered diesel engines?

- Will engineered diesel engines still be relevant in 2030?

- What materials are being engineered for lighter and stronger diesel engine components?

- References

What is Engineered Diesel?

Engineered diesel is the holistic optimization of both diesel fuel chemistry and engine mechanical systems to achieve superior thermal efficiency, durability, and minimal environmental impact. Unlike traditional setups, this approach integrates advanced molecular fuel design with precision hardware like high-pressure injection and digital control systems.

To truly understand this concept, one must look at it as a complete ecosystem rather than separate components. Engineered diesel represents a shift from passive consumption to active optimization. It involves:

· Fuel Science: Modifying the hydrocarbon chain for cleaner burns (e.g., HVO and synthetic blends).

· System Integration: Designing engine components that specifically capitalize on these advanced fuel properties.

· Digital Symbiosis: Using AI and ECU data to adjust combustion parameters in real-time.

According to recent market data, the global diesel engine market is projected to reach over $86 billion by 2033, driven largely by these high-efficiency, engineered solutions in the heavy-duty sector.

Key Takeaways: Engineered Diesel at a Glance

Engineered diesel combines chemical and mechanical innovation to extend equipment life and reduce total cost of ownership (TCO). This technology is not just about raw power; it is about precision.

· Holistic Design: Optimizes both the fuel source and the engine assemblies that consume it.

· Efficiency First: Recent breakthroughs have pushed thermal efficiency past 53%, a milestone once thought impossible.

· Future-Proof: Innovations focus on diesel technology that meets strict EPA 2027 and Euro 7 standards.

· Sustainability: Renewable fuels like HVO are central to keeping diesel engines relevant in a decarbonizing world.

The Evolution of Diesel Engineering: From Rudolf Diesel to Modern Marvels

Diesel engineering has evolved from rudimentary compression ignition to sophisticated, computer-controlled power systems capable of near-zero emissions. Early designs focused solely on torque, whereas modern iterations prioritize a balance of power, fuel economy, and environmental stewardship.

This journey highlights the resilience of the technology:

1. The Origins: Rudolf Diesel’s original design prioritized efficiency over the steam engine, using high compression ratios.

2. Turbo Era: The introduction of forced induction allowed smaller engines, like a 4 cyl diesel engine, to produce the power of much larger naturally aspirated units.

3. Electronic Revolution: The shift from mechanical governors to digital Engine Control Units (ECUs) enabled precise fuel delivery.

4. The Engineered Era: Today, we see integrated systems where diesel engine oil, fuel, and aftertreatment hardware are co-developed for maximum synergy.

Engineering Diesel Fuels: Beyond the Basic Hydrocarbon

Engineered diesel fuels are chemically modified or synthetically created fluids designed to outperform standard petroleum diesel in combustion stability, lubricity, and emissions profiles. Standard crude-derived diesel is often inconsistent, whereas engineered variants offer molecular uniformity.

Advanced fuel engineering addresses several critical performance metrics:

· Renewable Diesel (HVO): Hydrotreated Vegetable Oil is a drop-in replacement that reduces lifecycle emissions by up to 90%. The HVO market alone is projected to grow at a CAGR of over 18% through 2032.

· Cetane Boosters: Additives that ensure faster ignition, crucial for cold starts and smooth running in a 2 cylinder diesel engine or smaller industrial units.

· Lubricity Enhancers: Vital for protecting high-pressure fuel pumps, especially in ultra-low sulfur diesel (ULSD) blends.

· Detergents: Compounds that keep injectors clean, preventing the common need for fixing diesel engine fueling issues caused by deposits.

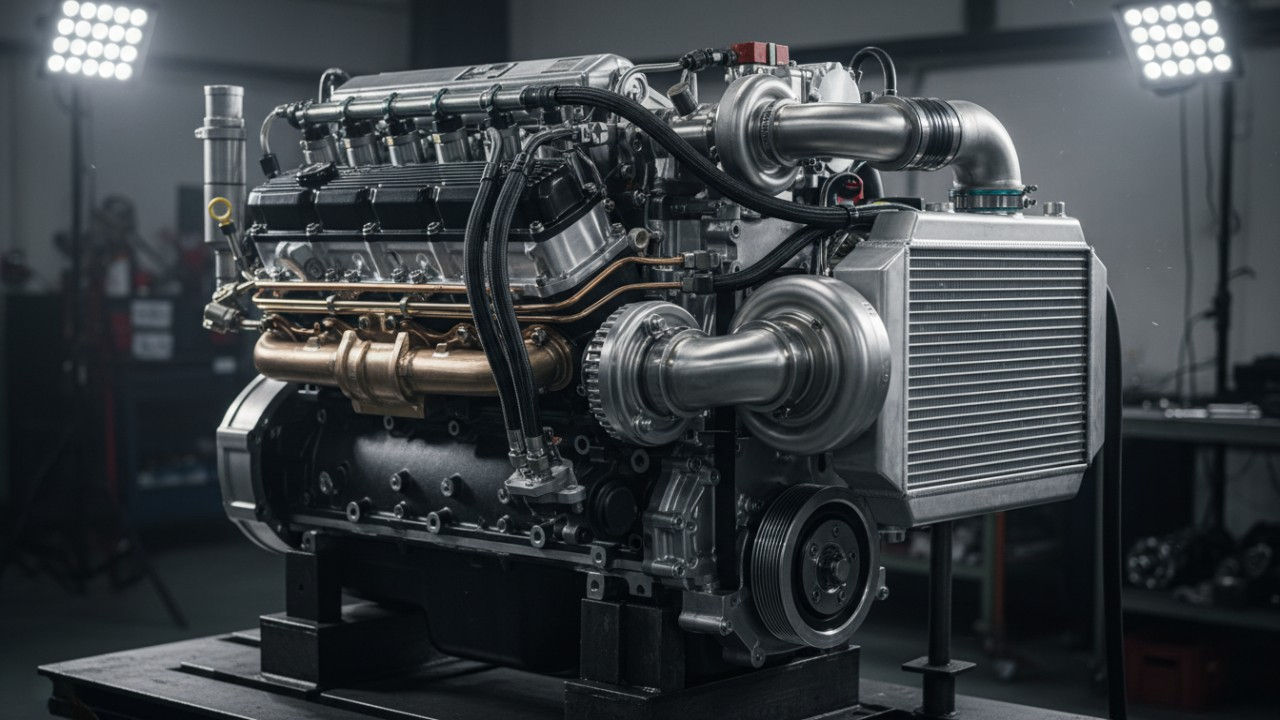

Precision Engineering in Diesel Engines: Components & Systems

Precision engineering in this context refers to the manufacturing of engine components with micron-level tolerances to handle immense pressures and temperatures. Modern best diesel engines operate at injection pressures exceeding 2,500 bar, requiring materials that can withstand extreme stress.

Key engineered subsystems include:

· Common Rail Injection: Allows for multiple injection events per cycle (pilot, main, post), smoothing out combustion and reducing noise.

· Variable Geometry Turbochargers (VGT): Adjust airflow dynamically, ensuring an excavator engine has torque instantly upon demand without lag.

· Advanced Materials: The use of Vermicular Graphite Iron (CGI) allows blocks to be lighter yet stronger.

· Aftertreatment Systems: Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPF) are now integrated into the engine's thermal management strategy.

If you are sourcing heavy-duty components, finding a reliable Cummins QSK23 Engine Assembly Wholesale Supplier is critical for ensuring you get these precision-engineered standards.

The Future Landscape: Engineered Diesel Innovations Beyond 2026

Future diesel innovations will center on hybridization, connectivity, and fuel-agnostic architectures that allow engines to transition seamlessly between diesel, hydrogen, and natural gas. As we look past 2026, the "death of diesel" appears exaggerated; instead, it is transforming.

Expect to see these technologies dominate:

1. AI-Optimized Performance: On-board AI will predict load changes and adjust diesel engine service intervals dynamically based on real-world usage data.

2. Hybrid Powertrains: Diesel-electric hybrids will become standard in off-highway equipment, recovering energy during braking or swing movements in excavators.

3. Fuel-Agnostic Platforms: Manufacturers are building "bottom ends" that can support heads designed for diesel, hydrogen, or biomethane.

4. Thermal Efficiency Gains: New piston bowl geometries and insulation coatings aim to capture waste heat, pushing efficiency toward 55%.

Why Engineered Diesel Matters: Benefits Across Industries

Engineered diesel solutions deliver unmatched reliability and power density, which are non-negotiable for industries like mining, marine, and logistics. While electrification suits passenger cars, heavy industry requires the energy density that only liquid fuels can provide.

· Total Cost of Ownership (TCO): Higher efficiency means lower fuel bills, which constitute the largest operational cost.

· Durability: An engineered 3 cyl diesel engine in a generator can run for tens of thousands of hours with proper care.

· Torque Availability: Essential for moving heavy loads; diesel engines for sale today offer more torque per liter than ever before.

· Resale Value: Equipment with a reputation as the most reliable diesel engine retains value significantly better.

Expert Tips for Maximizing Engineered Diesel Performance & Lifespan

Maximizing performance requires a strict adherence to maintenance protocols that respect the precision of modern machinery. Cutting corners on fluids or filtration is the fastest way to destroy a high-tech engine.

Follow these expert-backed strategies:

· Fluid Quality is King: Never compromise on diesel engine oil. Use synthetic oils with the correct API service category (e.g., CK-4 or FA-4) to handle high soot loads.

· Filtration Matters: Modern injectors are intolerant of debris. Use OEM-spec filters to prevent microscopic damage.

· Monitor Idle Time: Excessive idling causes "wet stacking" and clogs DPFs. Turn off the engine if not in use for extended periods.

· Periodic Cleaning: Perform a diesel engine flush if you suspect sludge buildup, but only use products approved by the manufacturer.

· Inspect Cooling Systems: Overheating is a primary killer. regularly check coolant acidity and levels.

For those maintaining heavy machinery, properly identifying replacement components is vital. Check out our guide on Excavator Parts to ensure you are selecting the right grade of equipment.

Common Misconceptions About Modern Engineered Diesel

Misconceptions often stem from outdated experiences with old, smoky engines, ignoring the clean and quiet reality of modern technology. It is crucial to separate historical myths from current engineering facts.

· Myth: Diesel is always dirty.

o Fact: A 2024 model year diesel emits 98% less NOx and particulate matter than a model from 1988.

· Myth: Diesel engine maintenance is too expensive.

o Fact: While per-service costs are higher (~68% more than gas), intervals are longer, and engine longevity is often double that of gasoline counterparts.

· Myth: Diesels can't run in the cold.

o Fact: Engineered fuels and modern glow plug systems enable reliable starts even in sub-zero temperatures.

· Myth: All diesel engines for sale are the same.

o Fact: There is a massive quality gap between a budget generic engine and a precision-engineered unit from a top-tier manufacturer.

The Road Ahead: Challenges and Opportunities for Engineered Diesel

The primary challenge facing the industry is navigating tightening emissions regulations while maintaining the performance users demand. However, this pressure is also the catalyst for the most exciting engineering developments.

Opportunities lie in:

1. Sustainable Fuels: The widespread adoption of HVO will allow legacy fleets to decarbonize overnight without hardware changes.

2. Digital Twins: Using virtual models to simulate wear and optimize diesel engine maintenance schedules before a failure occurs.

3. Circular Economy: Remanufacturing engine assemblies reduces waste and energy consumption compared to casting new blocks.

Conclusion

Engineered diesel is far from a dying technology; it is a rapidly evolving field that bridges the gap between our heavy-industrial needs and a sustainable future. By understanding the intricate balance of fuel chemistry, thermal dynamics, and digital control, businesses can leverage these power plants for decades to come. Whether you are running a massive excavator engine or a compact generator, investing in engineered quality ensures peak performance and environmental responsibility.

FAQ

What is the main purpose of engineering diesel fuel?

Engineering diesel fuel aims to enhance combustion efficiency, improve lubricity, and reduce harmful emissions by optimizing the chemical structure of the hydrocarbon chain. This results in cleaner burns, better cold-start performance, and extended longevity for the fuel injection system.

How do engineered diesel engines achieve better fuel efficiency?

Engineered diesel engines achieve superior efficiency through high-pressure common rail injection (2,500+ bar), variable geometry turbocharging, and advanced thermal management. These technologies work in unison, controlled by AI-driven ECUs, to extract the maximum amount of energy from every drop of fuel.

Are renewable diesel fuels considered "engineered diesel"?

Yes, renewable diesel fuels like HVO (Hydrotreated Vegetable Oil) are the pinnacle of engineered fuels. They are synthetically manufactured to be chemically identical to premium petroleum diesel but with higher cetane numbers, zero sulfur, and significantly lower lifecycle carbon emissions.

What role does AI play in the future of engineered diesel technology?

AI plays a critical role in real-time predictive maintenance and combustion optimization. Beyond 2026, AI systems will continuously analyze sensor data to adjust fuel timing and air-fuel ratios, preventing failures and maximizing uptime without human intervention.

How do modern emissions control systems in engineered diesel engines work?

Modern emissions systems utilize a multi-stage approach including Exhaust Gas Recirculation (EGR) to lower combustion temperatures, Diesel Particulate Filters (DPF) to trap soot, and Selective Catalytic Reduction (SCR) to convert nitrogen oxides into harmless nitrogen and water.

What are the advantages of common rail fuel injection in engineered diesel engines?

Common rail injection decouples fuel pressure from engine speed, allowing for high injection pressure even at low RPMs. This enables multiple injection events per combustion cycle, which drastically reduces engine noise, vibration, and emissions while improving torque.

Will engineered diesel engines still be relevant in 2030?

Yes, engineered diesel engines will remain essential for heavy-duty applications like shipping, mining, and long-haul transport. While passenger vehicles electrify, the energy density required for heavy industrial work ensures diesel's relevance, especially when paired with renewable fuels.

What materials are being engineered for lighter and stronger diesel engine components?

Advanced materials such as Vermicular Graphite Iron (CGI), aluminum-lithium alloys, and ceramic-matrix composites are being used to reduce weight while increasing structural rigidity. These materials allow engines to withstand higher combustion pressures without a penalty in weight.

References

· Top Diesel Engine Innovations to Watch in 2025

· Diesel engine efficiency improvements: 7 Powerful Proven Gains 2025

· Diesel Engine Market Size, Share & Trends Analysis 2025-2033

· HVO Fuel Market 2025 forecast to 2032

· Maintenance Costs Increase 7% in H1 2024 - Automotive Fleet

FAQ

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -