jackhuang5919@gmail.com

Excavator Engine Fuel Efficiency: 7 Secrets to Slashing Your Operating Costs (2026 Update)

- Introduction: The Rising Cost of Power

- Key Takeaways: Quick Efficiency Guide

- What affects excavator engine fuel efficiency?

- Secret 1: The 'Clean Air, Clean Fuel' Mandate

- Secret 2: Eliminating the 'Phantom Burn' of Idling

- Strategies to Stop the Burn:

- Secret 3: Mastering Hydraulic Pump Synchronization

- Secret 4: Optimizing Work Modes (It's Not Just a Button)

- Mode Selection Guide:

- Secret 5: Proactive Turbocharger & Injector Care

- Secret 6: Decoding Telematics for Fuel Gains

- Actionable Telematics Insights:

- Secret 7: Navigating Tier 4 & Stage V Aftertreatment

- Gap Analysis: Future Trends in Engine Technology (2026+)

- Conclusion

- FAQ

- How often should I change my excavator engine oil for maximum efficiency?

- Does auto-idle actually save significant fuel?

- What are the signs of a failing fuel injection pump?

- Can using a higher viscosity oil improve engine performance?

- How does the hydraulic system affect engine fuel burn?

- Is it worth rebuilding an older excavator engine for efficiency?

- What is 'Wet Stacking' in diesel engines?

- How do Tier 4 Final engines differ in maintenance?

Introduction: The Rising Cost of Power

In the heavy machinery sector, the excavator engine is the heartbeat of your operation—and your biggest expense. As fuel prices fluctuate and 2026 maintenance costs rise, simply owning a machine is no longer enough; you must optimize it. Fuel consumption typically accounts for 40-60% of total machine operating costs, meaning even a small efficiency gain translates to thousands of dollars saved annually per unit.

Efficiency isn't just about buying the best diesel engine on the market; it is about how you manage, maintain, and operate that power plant. Whether you are running a small diesel engine in a compact mini-excavator or a massive turbo diesel engine in a 50-ton mining shovel, the principles of combustion and fluid dynamics remain the same. This guide moves beyond basic advice, offering engineered solutions to slash your overhead.

Key Takeaways: Quick Efficiency Guide

- Filtration is Finance: 80% of efficiency loss stems from contaminated fluids; high-quality filters are your first line of defense.

- The Idling Killer: Operator habits, specifically unnecessary idling, burn more cash than mechanical wear.

- Data is King: Modern ECU mapping and telematics are essential for meeting 2026 efficiency standards.

- System Sync: A healthy engine means nothing if the hydraulic pump isn't calibrated to match its output.

What affects excavator engine fuel efficiency?

Excavator engine fuel efficiency is primarily determined by air/fuel filtration quality, hydraulic load synchronization, operator idling habits, and the condition of the fuel injection system. Poor maintenance in these critical areas can increase fuel consumption by up to 30% without increasing productivity.

To understand efficiency, you must look at the "Work-to-Fuel" ratio. This metric measures how much dirt is moved per gallon of diesel burned. When an engine has to overcome internal friction from dirty oil, backpressure from a clogged DPF, or drag from a desynchronized hydraulic pump, it burns more fuel to generate the same amount of hydraulic power. Incomplete combustion, often caused by worn diesel engine parts, results in black smoke—a visual sign of wasted money leaving your exhaust pipe.

- Air Intake Restrictions: A clogged air filter forces the engine to work harder to breathe.

- Fuel Quality: Water or particulates in diesel disrupt the precise spray pattern of injectors.

- Hydraulic Load: If the pump demands more power than the engine is tuned to give at a specific RPM, the engine bogs down and guzzles fuel.

Secret 1: The 'Clean Air, Clean Fuel' Mandate

The single most effective way to maintain fuel efficiency is ensuring that only hospital-grade clean air and fuel enter your combustion chamber. Modern High-Pressure Common Rail (HPCR) systems operate at pressures exceeding 30,000 PSI, making them intolerant to debris.

At Guangzhou Weihu Engineering Machinery Parts Co., Ltd (Weihuparts), our R&D team has observed that aftermarket air filters failing to meet OEM micron ratings are a leading cause of premature efficiency loss. When microscopic dust bypasses a cheap filter, it acts as a sandpaper compound inside the cylinder, wearing down piston rings and reducing compression. Lower compression means the engine must burn more fuel to generate the same power.

Furthermore, water in fuel is devastating. As noted by the U.S. Environmental Protection Agency (EPA), strict adherence to fuel standards is critical for modern emission control systems. Water expands rapidly under heat, potentially blowing off injector tips.

- Install Water Separators: Essential for regions with older diesel supplies to protect your excavator engine.

- Use Premium Filtration: sourcing high-quality filtration kits from reputable suppliers like Weihuparts ensures optimal airflow.

- Regular Flushing: A diesel engine flush during oil changes can remove sludge that creates internal drag.

Secret 2: Eliminating the 'Phantom Burn' of Idling

Idling is the practice of running the engine while the machine is stationary, which can burn up to 0.8 gallons of fuel per hour while producing zero productivity. Data suggests that the average excavator idles for 30-40% of its total runtime.

Prolonged idling is not just a waste of fuel; it is actively damaging to the engine. It causes a condition known as "wet stacking," where low cylinder temperatures prevent the fuel from burning completely. This unburned fuel washes oil off the cylinder walls and creates carbon buildup on valves and turbochargers. According to Volvo Construction Equipment, excessive idling leads to carbon buildup and fuel dilution, significantly shortening engine life.

Strategies to Stop the Burn:

- Auto-Idle Features: Ensure your machine's auto-idle software is active and set to the shortest delay.

- Operator Training: Enforce a "Key Off" protocol for waits longer than 5 minutes.

- Site Logistics: Optimize dump truck cycles so excavators aren't waiting for trucks.

Secret 3: Mastering Hydraulic Pump Synchronization

Fuel efficiency is maximized when the engine's power curve is perfectly calibrated to the hydraulic pump's flow demand. If these two components are desynchronized, the engine will either stall or run at high RPMs without generating necessary hydraulic pressure.

Think of the excavator engine as the heart and the hydraulic pump as the muscle. If the muscle tries to lift a weight the heart can't support, the system fails. Symptoms of desynchronization include the engine bogging down under load or emitting black smoke. By calibrating the main pump flow to match the engine's torque curve, you ensure every drop of fuel translates into bucket movement.

- Load-Sensing Systems: Modern machines use load-sensing hydraulics to adjust engine RPM automatically.

- Periodic Calibration: Have a technician check pump pressures annually.

- Fluid Viscosity: Use the correct hydraulic fluid to reduce the physical effort required by the pump.

Secret 4: Optimizing Work Modes (It's Not Just a Button)

Selecting the correct work mode adjusts the engine throttle response and hydraulic pump output to match the specific intensity of the task. A common error is leaving a machine in "Power" or "High" mode for light tasks like grading or lifting.

Modern engineered diesel systems have sophisticated ECUs with distinct maps for Power (P), Economy (E), and Lifting (L). "Power" mode provides maximum RPM and hydraulic flow, ideal for hard digging but wasteful for anything else. "Economy" modes often reduce fuel consumption by 15-20% by flattening throttle spikes, forcing the operator to be smoother.

Mode Selection Guide:

- Power Mode: Heavy digging, breaking rock, or uphill travel.

- Economy Mode: General earthmoving, loading loose material, and grading.

- Fine/Lift Mode: Precision placement of pipes or trench boxes.

Secret 5: Proactive Turbocharger & Injector Care

The turbocharger and fuel injectors are the lungs and heart of your diesel engine; their condition directly dictates combustion efficiency. A failing turbo limits air supply, causing a "rich" burn that wastes fuel and overheats the engine.

If you are looking for a turbo diesel engine replacement or parts, quality matters. A worn injector might drip fuel instead of misting it. This "dribble" doesn't burn during the power stroke; instead, it creates hot spots that can melt pistons—a catastrophic failure that costs far more than a set of injectors. For fleet managers considering The Strategic Procurement of High-Performance Excavator Parts, prioritizing OEM-standard injectors is non-negotiable.

- Listen for Whistles: A loud whine from the turbo indicates bearing wear or air leaks.

- Watch for Smoke: Black smoke under load usually points to injectors or air restriction.

- Cool Down: Always idle the engine for 2 minutes before shutdown to protect the turbo bearings.

Secret 6: Decoding Telematics for Fuel Gains

Telematics systems leverage onboard sensors to track fuel burn rates, idle times, and fault codes in real-time. Platforms like KOMTRAX or Cat Product Link allow you to see exactly which machines are profitable and which are bleeding cash.

By analyzing this data, you can identify "lazy" assets—machines that are burning fuel but not moving dirt. You might find that a specific operator idles for 50% of their shift, or that a machine's fuel burn spikes abnormally, indicating a dragging brake or failing component. Weihuparts supports this data-driven approach by offering diesel engine parts that meet the precise specifications required by these monitoring systems.

Actionable Telematics Insights:

- Alerts: Set automatic alerts for fuel consumption spikes.

- Geofencing: Ensure machines aren't being used (and burning fuel) off-hours.

- Maintenance: Switch from hourly maintenance to fuel-burn-based maintenance for higher accuracy.

Secret 7: Navigating Tier 4 & Stage V Aftertreatment

Modern Tier 4 Final and Stage V engines utilize Diesel Particulate Filters (DPF) and Diesel Exhaust Fluid (DEF) to reduce emissions, but these systems increase backpressure if not maintained. A clogged DPF acts like a potato in the tailpipe, strangling efficiency.

Operators must understand "Regeneration." When the machine signals a regen cycle, it injects extra fuel to burn off soot in the DPF. Interrupting this cycle wastes that fuel and clogs the filter further. As we look toward The Future of Engineered Diesel, managing these aftertreatment systems is crucial for compliance and economy.

- Don't Interrupt Regen: Let the cycle finish to avoid "derate" modes.

- Clean Fluids: Keep DEF clean; dirt in the DEF tank can shut down the whole system.

- Ash Cleaning: DPFs eventually need physical cleaning to remove non-combustible ash.

Gap Analysis: Future Trends in Engine Technology (2026+)

While current strategies focus on optimization, the market for diesel engines for sale is shifting. We are seeing a rise in Hybrid Diesel-Electric systems where a smaller diesel engine charges a battery that handles the peak hydraulic loads. This allows for a most reliable diesel engine setup that runs at a constant, efficient RPM.

Furthermore, hydrogen internal combustion engines are emerging as a potential alternative for heavy equipment. However, for the next decade, the best diesel engine strategy remains proactive maintenance and smart operation. Investing in adaptable engine platforms now, supported by a partner like Weihuparts, ensures you are ready for these shifts.

Conclusion

Slashing operating costs in 2026 requires a holistic approach to excavator engine management. It is not enough to simply find a diesel engine for sale; you must maintain it with hospital-grade filtration, eliminate wasteful idling, synchronize your hydraulics, and respect the aftertreatment systems. By implementing these 7 secrets—ranging from operator behavior changes to data-driven maintenance—you can protect your bottom line and extend the life of your fleet. Efficiency is a daily discipline, not a one-time repair.

Contact us today to optimize your excavator engine strategy and source high-efficiency replacement parts.

FAQ

How often should I change my excavator engine oil for maximum efficiency?

Typically, oil should be changed every 250 to 500 hours, depending on the model and oil quality. However, using synthetic oils and high-quality filters from Weihuparts can extend these intervals. Always rely on oil analysis (SOS) rather than guessing, as this provides definitive data on engine health.

Does auto-idle actually save significant fuel?

Yes, auto-idle can reduce fuel consumption by 15-20% daily. It works by automatically dropping engine RPMs when hydraulic levers are in neutral for a set time (usually a few seconds). This reduces unnecessary combustion cycles during brief pauses, saving significant amounts of fuel over a work shift.

What are the signs of a failing fuel injection pump?

Common signs include difficulty starting the engine (especially when hot), a noticeable loss of power under load, excessive black or white exhaust smoke, and engine surging or uneven idle. If you notice these issues, inspect the diesel engine parts immediately to prevent further damage.

Can using a higher viscosity oil improve engine performance?

Not necessarily; you must follow the manufacturer's climate chart. While some believe thicker oil protects better, too thick oil increases internal drag, reducing fuel efficiency. Conversely, too thin oil risks metal-on-metal contact and catastrophic failure.

How does the hydraulic system affect engine fuel burn?

The engine powers the hydraulic pump; if the pump is inefficient, the engine works harder. Clogged hydraulic filters force the engine to burn more fuel to push fluid through the restriction. Improper relief valve settings can also cause the engine to strain unnecessarily against high pressure.

Is it worth rebuilding an older excavator engine for efficiency?

Yes, if the core components are sound. A rebuild with modern kit parts can restore near-factory efficiency. However, you should compare the costs against a remanufactured "drop-in" diesel engine for sale, which might offer a better warranty and faster turnaround.

What is 'Wet Stacking' in diesel engines?

Wet stacking is a condition where unburned fuel accumulates in the exhaust system, creating a black, oozy substance. It is caused by prolonged idling or operating at very light loads where the engine never reaches optimal temperature. It reduces efficiency and can cause permanent cylinder damage.

How do Tier 4 Final engines differ in maintenance?

Tier 4 Final engines require Ultra-Low Sulfur Diesel (ULSD) and CJ-4/CK-4 low-ash oil. Maintenance includes DPF cleaning (regeneration) and Diesel Exhaust Fluid (DEF) management. Neglecting these systems leads to 'derate' modes, where the computer limits speed and power to protect the engine.

FAQ

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

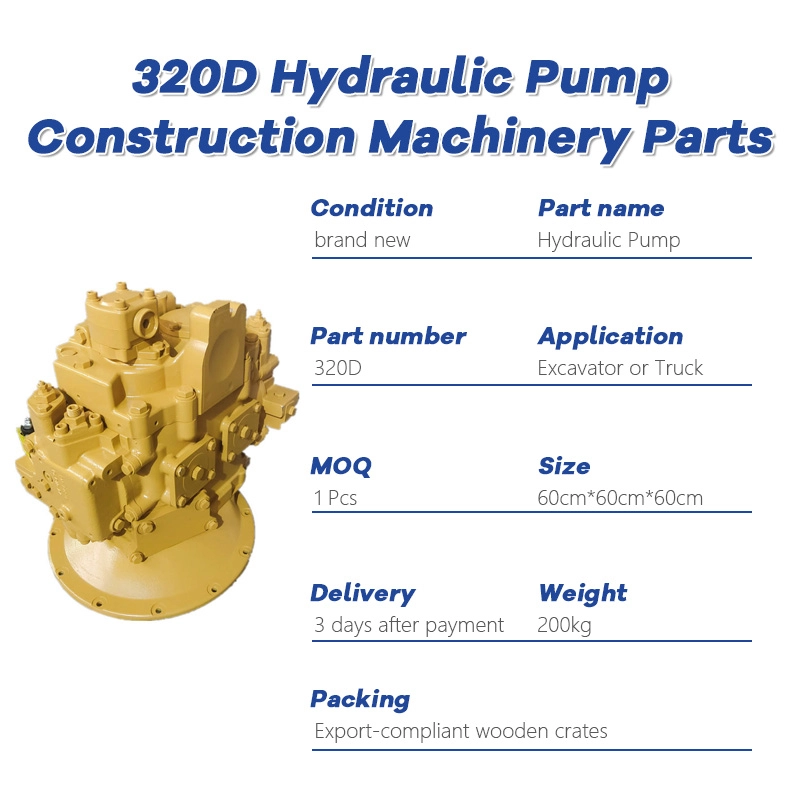

This high-performance SBS120 hydraulic pump is specially designed for the CAT 320D excavator. Built with premium materials and precision manufacturing, it ensures reliable power delivery and long-lasting performance in tough construction environments. Ideal as an OEM replacement or aftermarket solution, this pump supports your hydraulic system with smooth, efficient operation.

-

Fits: Caterpillar 320D

-

Model: SBS120

-

Application: Excavator main hydraulic pump

-

Condition: New / Aftermarket available

-

Warranty: 6-12 months (optional)

-

Worldwide shipping available

-

The CAT 980H and 980G hydraulic pumps are engineered to provide optimal hydraulic power and durability for Caterpillar loaders. Built with premium materials and precision manufacturing, these pumps are ideal for OEM replacements and high-quality aftermarket upgrades. They ensure smooth hydraulic operation and reliable performance in demanding construction environments.

-

✔️ Direct fit for CAT 980H and 980G loaders

-

✔️ Available in OEM and aftermarket versions

-

✔️ High-pressure, heavy-duty hydraulic performance

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for durability and efficiency

-

✔️ Fast global shipping and excellent customer support

- 🛒 Order your CAT 980H & 980G Hydraulic Pump now!

📞 Contact us for bulk orders, technical support, or custom requests.

📦 Fast worldwide shipping | OEM & aftermarket options available -

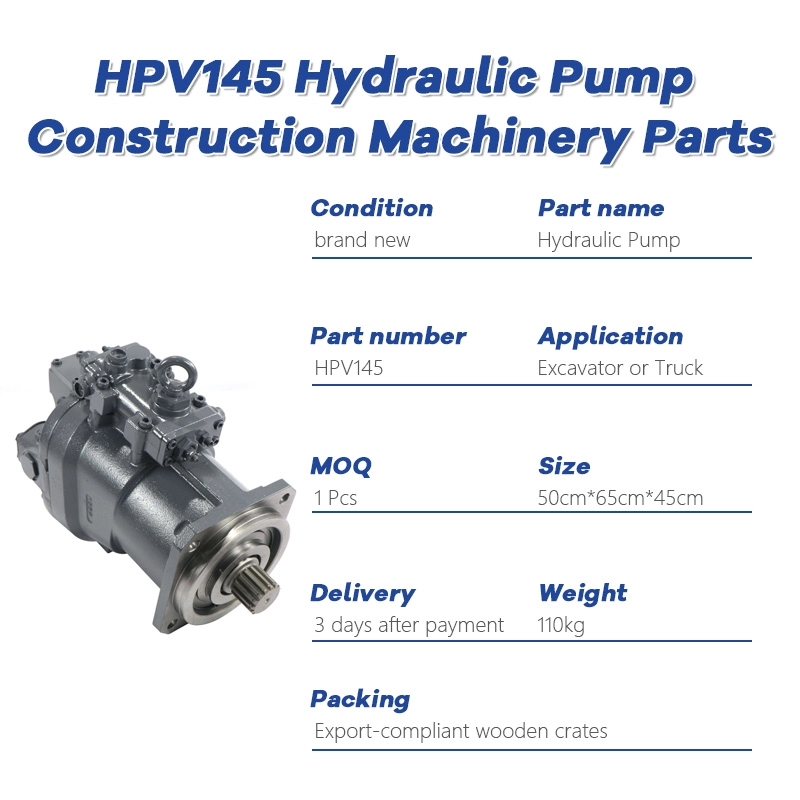

The HPV145 single pump with direct injection technology is designed for excavators and heavy-duty machinery requiring precise hydraulic control and efficient power delivery. Combining advanced direct injection control with durable axial piston pump construction, this model ensures high performance, long service life, and reliable operation. Available in OEM and aftermarket versions, it is ideal for replacement or system upgrades.

-

✔️ Direct injection electronic control for precise hydraulic output

-

✔️ Suitable for excavators and various heavy machinery

-

✔️ High-pressure axial piston single pump design

-

✔️ OEM and aftermarket options for flexibility and cost-effectiveness

-

✔️ Robust materials and quality seals for long-term durability

-

✔️ Fast worldwide shipping and comprehensive technical support

- 🛒 Order Your HPV145 Direct Injection Single Pump Today – Precision, Durability & Performance

📞 Contact Us for pricing, availability, and technical support

🌍 Fast Global Shipping | OEM & Aftermarket | Secure Payment Options -

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -