jackhuang5919@gmail.com

Why Your Hydraulic Pump is Failing: 10 Red Flags You Can't Ignore (2026 Guide)

- Introduction

- What are the most common signs of a failing hydraulic pump?

- The Importance of Early Diagnostics

- Auditory Red Flags: Listening to Your System

- Flag #1: High-Pitched Whining (Aeration)

- Flag #2: The "Marbles" Sound (Cavitation)

- Flag #3: Mechanical Knocks or Banging

- Thermal and Visual Red Flags

- Flag #4: Excessive Heat Generation

- Flag #5: External Seal Leakage

- Flag #6: Discolored or "Milky" Fluid

- Performance-Based Red Flags

- Flag #7: Slow Cycle Times

- Flag #8: Failure to Build Pressure

- Flag #9: Jerky or Erratic Cylinder Movement

- Flag #10: Frequent Filter Clogging

- Expert Analysis: The Root Causes

- Contamination: The #1 Killer

- Fluid Viscosity Issues

- Over-Pressurization

- The Cost of Ignoring Red Flags

- The Weihuparts Advantage

- Conclusion

- FAQs

- What does a hydraulic pump do in an excavator?

- What are the common types of excavator hydraulic pumps?

- What are the signs of a failing hydraulic pump?

- How long does an excavator hydraulic pump last?

- Can an aftermarket or remanufactured hydraulic pump replace an OEM pump?

Introduction

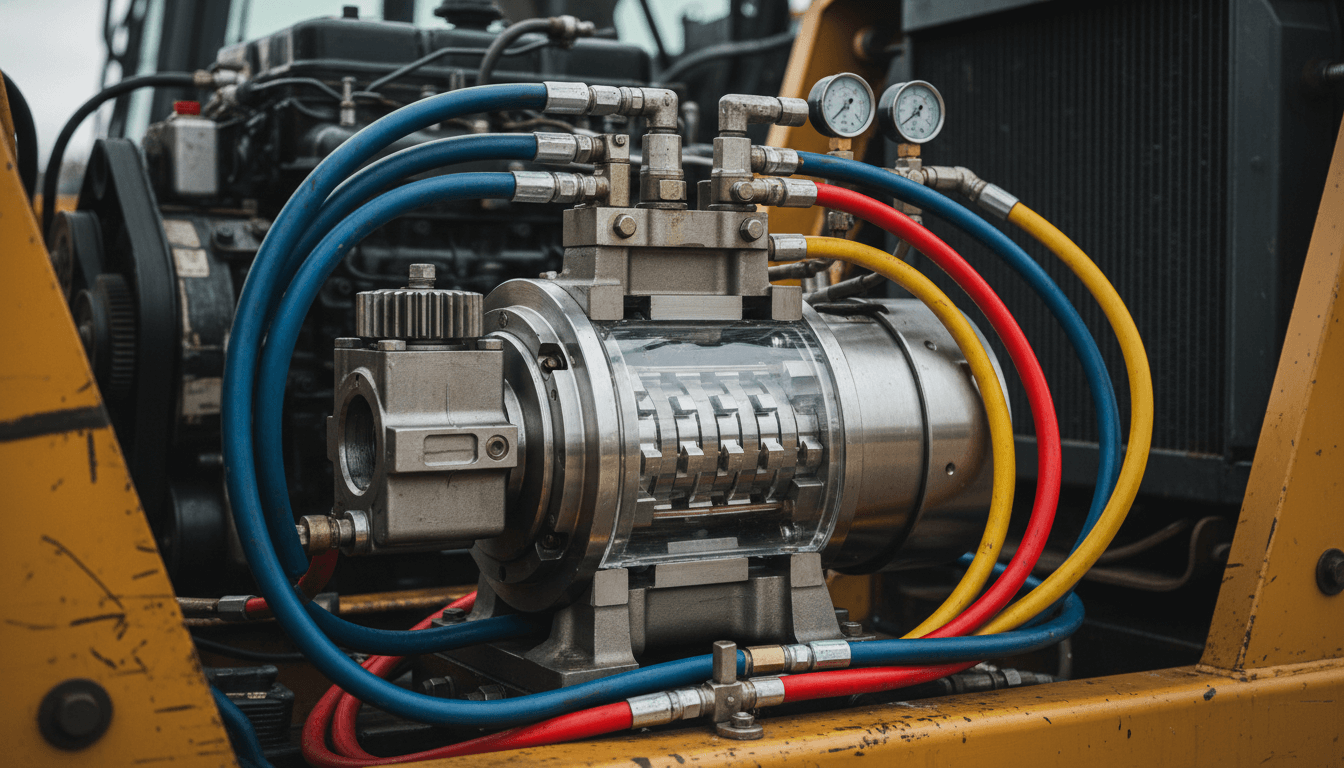

A failing hydraulic pump can instantly turn a profitable project into a logistical nightmare, costing thousands in unscheduled downtime. Whether you are operating a PTO driven hydraulic pump on a tractor or a high-precision electric hydraulic pump in an industrial setting, early detection is the only way to save your system. This guide breaks down the 10 critical symptoms of failure and how to fix them.

What are the most common signs of a failing hydraulic pump?

The most common signs of a failing pump include abnormal auditory cues (whining or banging), excessive heat generation above 180°F, visible fluid leaks, and sluggish cycle times. Identifying these symptoms early allows operators to perform hydraulic pump repair before catastrophic damage destroys the entire system.

The Importance of Early Diagnostics

Ignoring these signs doesn't just damage the pump; it contaminates your entire hydraulic circuit. When a pump disintegrates, it sends metal shards downstream, ruining valves, cylinders, and expensive hydraulic components. For operators sourcing parts of excavator machinery, understanding these red flags is essential for maintaining ROI.

If you are unsure about the basics of your system's core component, check our guide: What Is a Hydraulic Pump?.

Auditory Red Flags: Listening to Your System

Sound is often the first indicator of trouble. A healthy pump produces a consistent hum; any deviation suggests internal distress.

Flag #1: High-Pitched Whining (Aeration)

Aeration occurs when air enters the hydraulic fluid stream, creating a distinct, high-pitched screeching or whining noise. This typically happens due to air leaks in the suction line or low fluid levels in the reservoir. The air bubbles compress and explode under pressure, eroding metal surfaces.

Flag #2: The "Marbles" Sound (Cavitation)

Cavitation is frequently confused with aeration but has a different cause: restricted inlet flow. When the pump is starved of oil, vacuum bubbles form and implode with violent force, sounding like marbles or gravel rattling inside the housing. According to Machinery Lubrication, cavitation causes physical pitting on metal surfaces, leading to rapid structural failure.

Flag #3: Mechanical Knocks or Banging

Rhythmic banging or knocking usually indicates severe mechanical failure. This can be caused by:

- Worn Bearings: Allowing the shaft to wobble.

- Broken Gear Teeth: Causing a skip in the pumping cycle.

- Loose Couplings: Creating vibration between the motor and pump.

Thermal and Visual Red Flags

Visual inspections and temperature checks are vital for spotting hydraulic pump electric issues and mechanical wear before they stop production.

Flag #4: Excessive Heat Generation

Heat is a byproduct of inefficiency. If your pump is too hot to touch (safely), it is likely bypassing fluid internally due to wear. Most hydraulic systems should operate between 100°F and 140°F. Temperatures exceeding 180°F (82°C) degrade the oil's viscosity and harden seals, leading to leaks.

Flag #5: External Seal Leakage

Visible oil around the shaft seal or mounting flange is a clear red flag. While seals are wear items, premature failure often indicates:

- Excessive Case Pressure: The drain line may be clogged.

- Misalignment: Putting uneven stress on the shaft.

- Incompatible Fluid: Chemically attacking the seal material.

Flag #6: Discolored or "Milky" Fluid

Fluid analysis is the blood test of your machine.

- Milky Fluid: Indicates water contamination, which destroys lubrication properties.

- Dark/Burnt Fluid: Indicates overheating or oxidation.

- Glittery Fluid: Contains metal particles from internal component disintegration.

Performance-Based Red Flags

Operational changes are often subtle at first but escalate quickly. Whether you use a heavy-duty electric hydraulic pressure pump or a mobile excavator unit, watch for these performance drops.

Flag #7: Slow Cycle Times

If your excavator parts (like the boom or bucket) are moving slower than usual, the pump's flow rate (GPM) has likely decreased. This "sluggishness" is a classic sign of internal wear where oil slips past the gears or pistons rather than being pushed out to the work port.

Flag #8: Failure to Build Pressure

A pump that spins but cannot build pressure is effectively useless. This often points to:

- Severe Internal Leakage: The pump cannot hold the load.

- Relief Valve Failure: The fluid is being dumped back to the tank prematurely.

- Sheared Shaft: The internal mechanism isn't rotating even if the motor is.

Flag #9: Jerky or Erratic Cylinder Movement

Also known as the "stick-slip" phenomenon, jerky movement suggests inconsistent flow or trapped air. This can be dangerous, as it makes fine control of hydraulic components impossible, risking safety on the job site.

Flag #10: Frequent Filter Clogging

If you are changing filters more often than the manufacturer recommends, cut one open. Finding large metal flakes or debris means your pump is physically breaking apart. This is the final warning before a total system seizure.

Expert Analysis: The Root Causes

Understanding why these flags appear is key to prevention.

Contamination: The #1 Killer

Industry studies consistently show that 70% to 80% of all hydraulic system failures are caused by fluid contamination. Particulate matter acts like sandpaper, scouring the precision surfaces of the pump. To verify the cleanliness of your fluid, reference the ISO 4406 standard for particle counts.

Fluid Viscosity Issues

Using the wrong oil weight for your operating temperature can be disastrous. If the oil is too thin (low viscosity), it won't lubricate; if it is too thick (high viscosity), it causes cavitation.

Over-Pressurization

Tampering with the relief valve to get "more power" out of an electric hydraulic pump is a common mistake. Exceeding the design pressure spikes stress on bearings and shafts, drastically shortening the pump's lifespan.

For a deeper dive into modern pump technologies that mitigate these risks, read about Types & Trends of Hydraulic Pumps.

The Cost of Ignoring Red Flags

The economic impact of ignoring these red flags extends far beyond the cost of a replacement pump.

- Downtime Costs: An excavator sitting idle can cost hundreds of dollars per hour in lost revenue.

- System Cleanup: If a pump fails catastrophically, the entire system must be flushed, and all filters and oil replaced.

- Safety Risks: unexpected failure of parts of excavator arms or lifts can injure personnel.

The Weihuparts Advantage

At Guangzhou Weihu Engineering Machinery Parts Co., Ltd, we understand that reliability is non-negotiable. Our brand, Weihuparts, serves global clients by providing high-performance excavator parts developed through rigorous R&D. By choosing premium components that meet OEM standards, you reduce the risk of premature failure and ensure your machinery withstands the harshest operational environments.

Conclusion

Detecting hydraulic pump failure starts with vigilance. By monitoring for the 10 red flags—from the distinct noise of cavitation to the visual warning of leaks—you can intervene early. Proactive maintenance is always cheaper than reactive repair. Whether you need a robust hydraulic pump electric unit or specialized hydraulic components, prioritizing quality parts and clean fluid will secure your fleet's future.

Contact Weihuparts today to discuss your specific needs and find the durable solutions your machinery deserves.

FAQs

What does a hydraulic pump do in an excavator?

The hydraulic pump is a core excavator part responsible for converting mechanical power from the engine into hydraulic energy. It supplies pressurized hydraulic oil to key systems such as the boom, arm, bucket, swing motor, and travel motors, enabling precise and powerful machine operation.

What are the common types of excavator hydraulic pumps?

The most common hydraulic pumps used in excavators are axial piston pumps, including variable-displacement and fixed-displacement designs. Variable-displacement piston pumps are widely used in modern excavators because they improve fuel efficiency, allow load sensing, and provide smoother control under varying operating conditions.

What are the signs of a failing hydraulic pump?

Typical warning signs of hydraulic pump failure include reduced operating speed, loss of digging power, abnormal noise or vibration, overheating hydraulic oil, and unstable or jerky movements. Early detection is critical, as pump failure can lead to contamination and damage to other hydraulic components.

How long does an excavator hydraulic pump last?

Under normal operating conditions and with proper maintenance, an excavator hydraulic pump can last 5,000 to 10,000 operating hours. Service life depends heavily on oil cleanliness, operating pressure, duty cycle, and adherence to recommended maintenance intervals.

Can an aftermarket or remanufactured hydraulic pump replace an OEM pump?

Yes, a high-quality aftermarket or remanufactured hydraulic pump can replace an OEM unit, provided it is manufactured or rebuilt to OEM specifications, including correct displacement, pressure rating, and control configuration. When sourced from a qualified supplier, these pumps can offer comparable performance and reliability at a lower total cost of ownership.

FAQ

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -