jackhuang5919@gmail.com

What Is a Hydraulic Pump? Types, Working & Applications

Explore hydraulic pumps: types, working principles, piston & electric pumps, and their key industrial applications.

- Introduction

- What Is a Hydraulic Pump?

- How Does a Hydraulic Pump Work?

- Working Principle

- Types of Hydraulic Pumps

- Table: Types of Hydraulic Pumps

- Applications of Hydraulic Pumps

- Key Applications of Hydraulic Pumps:

- How to Choose the Right Hydraulic Pump

- Hydraulic Pump Maintenance Tips

- Our Hydraulic Pump Solutions

- FAQs about Hydraulic Pump

- 1. What is the most common type of hydraulic pump?

- 2. How long do hydraulic pumps last?

- 3. What causes hydraulic pump failure?

- 4. How do I know if my hydraulic pump is bad?

- 5. Can hydraulic pumps be repaired?

- 6. Is an electric hydraulic pump better?

- 7. When should I choose a piston hydraulic pump?

- 8. Where can I find a hydraulic pump for sale?

- Conclusion

Introduction

A hydraulic pump is key to any hydraulic system because it converts mechanical energy into hydraulic energy. This power is used by industrial machines, construction equipment, and manufacturing systems. Hydraulic pumps are used in modern equipment to maintain stable pressure, ensure smooth operation, and provide long-lasting durability. No matter if you're using an electric hydraulic pump for automated systems or a portable hydraulic pump for mobile work, picking the right model is key. Today's industries need efficient hydraulic oil pump technology to improve power output and reduce maintenance costs, so it's important to understand the different types of hydraulic pumps.For a complete overview, check out our Hydraulic Pumps Guide 2026.

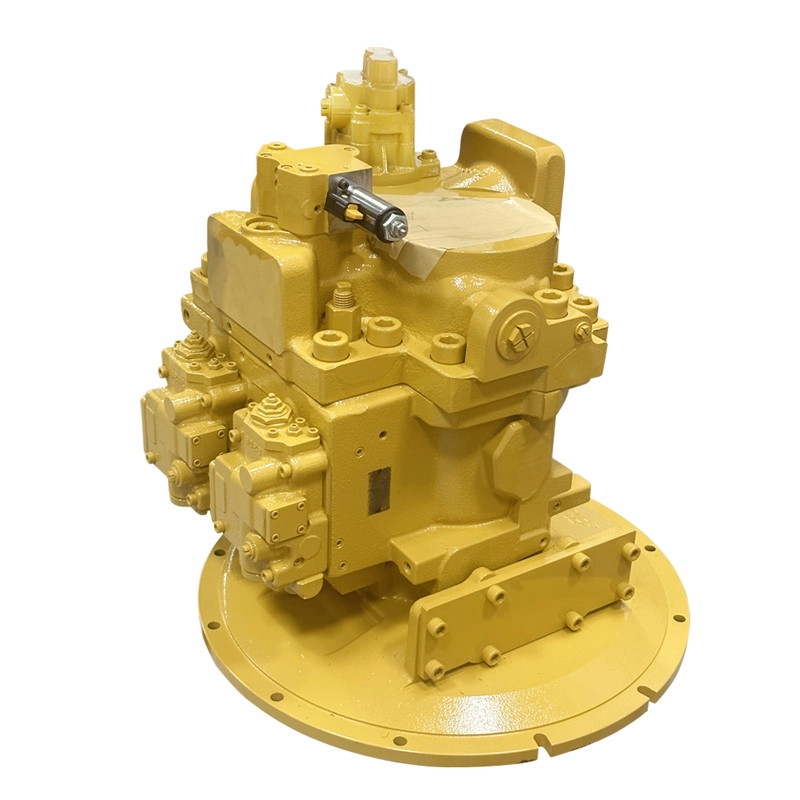

What Is a Hydraulic Pump?

A hydraulic pump is a device that creates flow and pressure in a hydraulic circuit, generating the power needed to move actuators and cylinders. Most hydraulic pumps work by drawing hydraulic fluid from a reservoir and forcing it into the system to create energy. Businesses often need different hydraulic pump parts based on the design, such as seals, pistons, gears, and swash plates. No matter what kind of hydraulic pump you're checking out, the goal is always the same: convert mechanical input into steady hydraulic output.

How Does a Hydraulic Pump Work?

If you're wondering how a hydraulic pump works, it's all about creating flow and changing pressure. A hydraulic pump creates low-pressure suction at its inlet and high-pressure discharge at its outlet, allowing hydraulic fluid to move through the system. Most hydraulic pumps use mechanical rotation from motors or engines to push hydraulic oil through internal chambers. This process makes it so an electric hydraulic pump or a hydraulic oil pump can deliver constant, reliable energy. Knowing how a hydraulic pump works can help you get more use out of it, reduce breakdowns, and keep it running smoothly.

Working Principle

A hydraulic pump basically takes mechanical energy and converts it into hydraulic energy. A piston hydraulic pump has pistons moving inside cylinders to generate high-pressure flow, while a gear hydraulic pump uses intermeshing gears to transfer energy to the hydraulic system. It works right when the hydraulic pump parts are the right size, the right amount of lubrication is used, and the system pressure is just right. Knowing how they work ensures that electric, portable, and standard hydraulic oil pumps will operate efficiently, reducing downtime and improving reliability.

Types of Hydraulic Pumps

There are numerous types of hydraulic pumps available, each with its own set of advantages for specific applications. Most industries use piston hydraulic pumps for high-pressure systems, while gear pumps and vane pumps are better for simple machinery. Knowing the types of hydraulic pumps helps operators pick the right hydraulic pump parts and avoid unnecessary downtime. Here's the recommended comparison format:

Table: Types of Hydraulic Pumps

| Pump Type | How It Works | Advantages | Applications |

|---|---|---|---|

| Gear Pump | Rotating gears trap and move oil | Low cost, reliable | Agriculture, small machines |

| Vane Pump | Sliding vanes create flow | Quiet, smooth | Industrial machinery |

| Axial Piston Pump | Pistons move parallel to the drive shaft | High pressure, durable | Excavators, CNC |

| Radial Piston Pump | Pistons arranged radially | Extremely high pressure | Heavy-duty systems |

| Bent-Axis Pump | Swash plate rotation changes displacement | Efficient, adjustable | Construction & mining |

| Fixed/Variable Displacement | Constant or adjustable flow | Flexible control | Automation & manufacturing |

Each type of hydraulic pump has its own strengths, and picking the right one affects how well the system performs, how energy efficient it is, and how much maintenance it costs.

Applications of Hydraulic Pumps

A hydraulic pump is key for industrial and mobile applications because it can handle heavy loads, provide precise control, and keep running. Most hydraulic pumps can handle high pressure and long hours. Depending on the task, operators might choose an electric hydraulic pump for automation and energy efficiency or a portable hydraulic pump for flexible field use. Picking the right hydraulic oil pump will make your equipment more productive, extend its lifespan, and reduce downtime. Knowing how different types of hydraulic pumps work helps engineers and technicians make the right decisions.

Key Applications of Hydraulic Pumps:

-

Construction Machinery:

-

Hydraulic pumps power excavators, loaders, and cranes, providing consistent force for lifting and digging. Many machines use piston hydraulic pumps or electric hydraulic pumps for precise control.

-

Agriculture & Forestry:

-

Hydraulic pumps drive agricultural sprayers, tractors, and logging equipment, ensuring efficient operation in the field. Portable hydraulic pumps are often preferred for mobile tasks.

-

Industrial Manufacturing:

-

Hydraulic pumps are critical for injection molding machines, CNC machinery, and metal forming systems. A reliable hydraulic oil pump improves precision and reduces production errors.

-

Marine & Shipping:

-

Ships and marine equipment use hydraulic pumps to operate steering, winches, and other heavy systems. Double acting hydraulic pumps or electric hydraulic pumps provide stable and efficient performance.

-

Mining & Heavy Equipment:

-

In mining, hydraulic pumps power drilling rigs, crushers, and loaders. Using the correct types of hydraulic pumps helps maintain safety and maximize efficiency.

How to Choose the Right Hydraulic Pump

When picking the right hydraulic pump, it's important to think about things like flow rate, pressure rating, fluid type, and how the system is designed. High-pressure systems often use a piston hydraulic pump, while simple machinery may only need gear pumps. When picking a hydraulic pump, it's important to consider things like temperature stability, duty cycle, noise level, and how well it'll work with your existing hydraulic pump parts. Some operations might prefer a fully automated electric hydraulic pump, while others need the flexibility of a double acting hydraulic pump for complex cylinders. Hey, just a friendly reminder to always compare specs before buying a hydraulic pump.

Hydraulic Pump Maintenance Tips

If you take care of it, your hydraulic pump will run smoothly and last a long time. Keeping the hydraulic fluid clean, checking the seals, and keeping an eye on the pump noise can help make the hydraulic pump last longer. It's crucial to keep oil free from contamination for any hydraulic oil pump, especially in high-pressure applications. Make sure you regularly inspect the hydraulic pump parts, like bearings and pistons, to avoid any downtime. Once operators know how hydraulic pumps work, it becomes easier to spot early warning signs like vibration, overheating, or inconsistent flow.

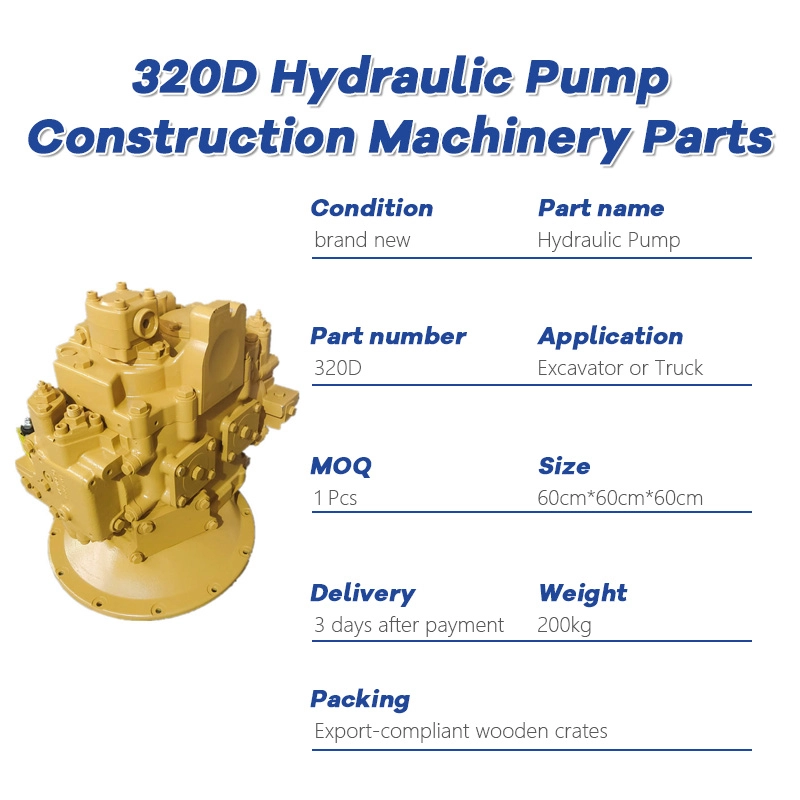

Our Hydraulic Pump Solutions

We've got all the hydraulic pump solutions you could need, including complete pumps and hydraulic pump parts that work with Caterpillar, Komatsu, Hitachi, Volvo, and other brands. Our catalog includes electric hydraulic pumps, piston hydraulic pumps, double acting hydraulic pumps, and durable hydraulic oil pumps for industrial use. Whether you need a 312D excavator hydraulic pump: a monologue of a "working pump"or custom parts, we've got you covered with dependable products built to last and perform at their best.

FAQs about Hydraulic Pump

1. What is the most common type of hydraulic pump?

The most common type of hydraulic pump is the gear pump because it's affordable, durable, and easy to maintain. A lot of industries go for gear-style hydraulic pumps for low- and medium-pressure systems. While electric and piston hydraulic pumps might be better for more complex tasks, gear pumps are still a go-to for simpler jobs. Their simple design also makes it easy to replace hydraulic pump parts and keep the system running for long periods with minimal downtime.

2. How long do hydraulic pumps last?

A normal hydraulic pump can last 5–10 years, but it depends on the load, temperature, and how well you take care of it. If you want your hydraulic pumps to work well, you've got to keep the oil clean, make sure the filters are working, and check on the pumps regularly. An electric hydraulic pump often lasts longer because of its stable motor control, while a portable hydraulic pump may wear faster from field use. Replacing worn hydraulic pump parts like seals and bearings can really extend the service life. It's key to keep your system clean and make sure the fluids are top-notch if you want it to perform well over time.

3. What causes hydraulic pump failure?

Most hydraulic pump failures are caused by contamination, overheating, cavitation, or low fluid levels. When hydraulic pumps run with dirty oil, they wear out faster and break down more quickly. If your filter is clogged, it can cause cavitation, which can damage even a strong piston hydraulic pump. If you don't use enough lubricant, it can also shorten the life of your hydraulic oil pump. If you regularly check the pressure, temperature, and parts of the hydraulic pump, you can prevent some pretty costly breakdowns. Preventive maintenance is key to avoiding sudden pump failure.

4. How do I know if my hydraulic pump is bad?

If your hydraulic pump is malfunctioning, you might hear strange noises, see slow operation, pressure drops, or overheating. If you've got hydraulic pumps that are operating with worn components, they might vibrate or lose efficiency. Even an electric hydraulic pump can have performance issues, like inconsistent flow or higher energy consumption. Taking a look at seals, bearings, and internal hydraulic pump parts can help you spot problems early on. If the pump doesn't reach its rated pressure, you might need to replace or repair it.

5. Can hydraulic pumps be repaired?

Yeah, a lot of hydraulic pump models can be fixed by replacing parts like pistons, gears, seals, and shafts. It's often cheaper to repair hydraulic pumps than to buy new ones, especially for big industrial systems. You can get an electric hydraulic pump or piston hydraulic pump back to near-new condition with quality hydraulic pump parts. But if the housing is damaged or the pump is really contaminated, replacement might be better in the long run.

6. Is an electric hydraulic pump better?

An electric hydraulic pump is great for manufacturing and automation because it's stable, energy efficient, and automatic. A lot of factories like electric hydraulic pumps because they deliver consistent pressure and work well with monitoring systems. But a portable hydraulic pump is better for field operations where there's no electricity. The best type of hydraulic pump depends on the environment and workload. They both perform well, but each is better for different things.

7. When should I choose a piston hydraulic pump?

A piston hydraulic pump is perfect for high-pressure, high-performance systems that need precision and constant operation. A lot of industries use piston hydraulic pumps in excavators, CNC equipment, and injection molding machines. Piston designs are more efficient and last longer than other types of hydraulic pumps. They might cost more than gear or vane pumps, but they're the go-to choice for tough environments because they work well with advanced hydraulic pump parts.

8. Where can I find a hydraulic pump for sale?

You can find a hydraulic pump for sale through industrial suppliers, OEM distributors, or specialized manufacturers. Our company's got all kinds of hydraulic pumps—like electric ones, portable ones, and piston ones—that'll work for whatever industry you've got going on. We also supply high-quality hydraulic pump parts for maintenance or replacement. Whether you need a single pump or bulk orders, choosing a trusted supplier ensures long life, stable performance, and competitive pricing.

Conclusion

A hydraulic pump is key to powering machinery in construction, manufacturing, agriculture, and automation. If you understand how hydraulic pumps work, the different types, and how to choose the right model, you can get better performance and reduce downtime. If you need an electric hydraulic pump, a portable hydraulic pump, or a high-pressure piston hydraulic pump, make sure you get good equipment and take care of all hydraulic pump parts. That way, you can count on your equipment for a long time. If you're looking for a reliable hydraulic pump, you can make a big difference in efficiency and lifespan.

FAQ

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -