jackhuang5919@gmail.com

Total Cost of Ownership: Excavator Hydraulic Pump for Fleet Managers

- Total Cost of Ownership: Excavator Hydraulic Pump for Fleet Managers

- Why the hydraulic hydraulic pump is central to excavator TCO

- Product spotlight: 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- Breaking down TCO for an excavator hydraulic pump (what fleet managers must track)

- How hydraulic pump performance affects fuel and productivity

- OEM vs Aftermarket vs Rebuilt: TCO comparison for fleet procurement

- Estimating downtime cost — how a pump failure affects the bottom line

- Preventive maintenance and monitoring to reduce TCO

- Installation, compatibility and warranty considerations (: hydraulic pump replacement)

- Rebuild vs replace: decision checklist

- Illustrative example: TCO scenario for a single CAT 336D pump over 5 years

- Brand and supplier considerations — why the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement can be a smart choice

- Practical procurement rules for fleet managers

- FAQs — Excavator hydraulic pump TCO and the 336D replacement

- Q: How often should the hydraulic pump on a CAT 336D be replaced?

- Q: Is it safer to buy OEM or aftermarket for my 336D pump?

- Q: Can a rebuild be as reliable as a new pump?

- Q: How do I minimize downtime when replacing a pump?

- Q: What is the most important maintenance action to extend pump life?

- Call to action — get the right pump and reduce your fleet TCO

- Authoritative references and further reading

- Contact / View product

Total Cost of Ownership: Excavator Hydraulic Pump for Fleet Managers

Why the hydraulic hydraulic pump is central to excavator TCO

For fleet managers responsible for uptime, budgets, and safety, the hydraulic hydraulic pump is not simply a component — it is a high-value system driver that influences fuel consumption, cycle times, maintenance intervals, and unplanned downtime. Understanding Total Cost of Ownership (TCO) for hydraulic pumps helps you move beyond purchase price and optimize lifecycle decisions across hundreds or thousands of machine-hours. Cost analysis must align with equipment compatibility. Reviewing the compatibility matrix: 336D pump fitment and performance factors ensures the selected pump delivers expected performance in real applications.

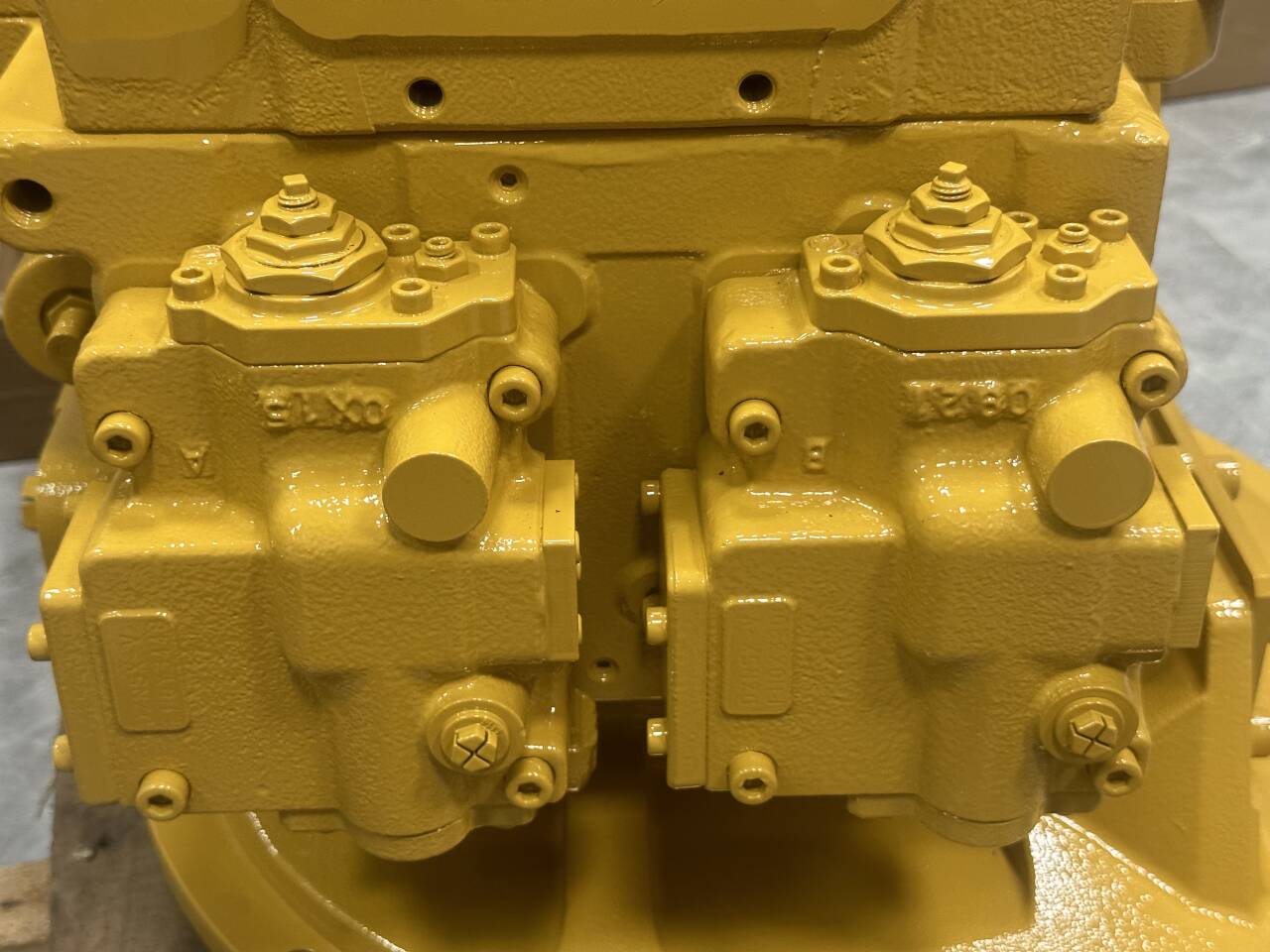

Product spotlight: 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Breaking down TCO for an excavator hydraulic pump (what fleet managers must track)

To make informed procurement choices, TCO should include hard and soft costs. Below are the core categories to quantify and monitor:

- Initial purchase price — OEM vs aftermarket unit cost, including freight and taxes.

- Installation and labor — shop hours, diagnostic time, hydraulic system flush and refill, calibration.

- Operating efficiency — pump volumetric and mechanical efficiency affect fuel consumption and cycle times.

- Maintenance and consumables — filter replacements, hydraulic oil changes, seals, periodic inspections.

- Downtime costs — lost production, rental replacements, crew idle time, contractual penalties.

- Repair or rebuild vs replacement — component-level repair costs and remaining useful life.

- Residual value and disposal — salvage or trade-in impacts on lifecycle economics.

How hydraulic pump performance affects fuel and productivity

Hydraulic pumps drive the hydraulic motors and cylinders that perform digging, lifting, and swinging. A pump running at suboptimal efficiency increases engine load and fuel burn. Even a 2–5% reduction in pump efficiency can translate into significant diesel cost increases across a large fleet. Monitoring pump flow, pressure stability, and slip (for gear pumps) gives early warning signs of wear.

OEM vs Aftermarket vs Rebuilt: TCO comparison for fleet procurement

Choosing between OEM, High Quality aftermarket, or rebuilt pumps depends on your fleet strategy. Below is a clear, practical comparison across the metrics fleet managers care about:

| Metric | OEM (New) | High Quality Aftermarket | Rebuilt/Reman |

|---|---|---|---|

| Initial cost | High | Moderate | Low–Moderate |

| Warranty | Manufacturer-backed (longer) | Supplier warranty (shorter) | Varies — limited |

| Fit & compatibility | Guaranteed | Usually direct fit | May require minor adjustments |

| Expected reliability | Highest consistency | High if High Quality | Depends on reman quality |

| Lead time | Often longer for new OEM parts | Faster availability for stocked lines | Can be fastest if reman in inventory |

| Lifecycle environmental impact | Higher new-manufacturing footprint | Lower than new | Lowest (recycling/upcycling) |

This table is designed to help fleet managers weigh trade-offs. Many fleets adopt a mixed strategy: OEM for critical machines with high uptime value, High Quality aftermarket for lower-criticality units, and rebuilt units for emergency or short-term coverage.

Estimating downtime cost — how a pump failure affects the bottom line

Downtime is usually the largest and least visible cost. To estimate, use this basic formula:

Downtime cost = (machine hourly revenue or replacement cost + crew idle cost + mobilization) × downtime hours

Example: If a 336D typically generates $180/hour in billable productivity (or avoids that cost when doing in-house work), a 12-hour unplanned pump failure equals $2,160 in lost productivity, plus any rental or overtime costs. Multiply across your fleet to see the real impact of reliability choices.

Preventive maintenance and monitoring to reduce TCO

Effective condition monitoring reduces unplanned failures and extends pump life. Key practices:

- Oil analysis for contamination and wear metals (ISO 4406 contamination codes and particle counts)

- Regular filter change schedules based on operating hours and environment

- Temperature and pressure trend logging to detect early seal or wear issues

- Proper system flushing when installing replacement or rebuilt pumps to avoid contamination-induced failures

- Using recommended hydraulic fluid viscosity and additives to minimize cavitation and wear

Investing in a simple sensor-and-telemetry package often pays back quickly by preventing catastrophic pump failures.

Installation, compatibility and warranty considerations (: hydraulic pump replacement)

When replacing a hydraulic pump on a CAT 336D, ensure the unit is a direct-fit model or a verified compatible option. Ask suppliers for:

- Cross-reference part numbers and serial compatibility

- Installation procedure and torque specs

- Warranty terms and remedies (turnaround, parts, labor)

- Documentation on testing and quality assurance for aftermarket or reman units

Improper installation or using a non-compatible pump can compromise system performance and void other equipment warranties — an expensive risk.

Rebuild vs replace: decision checklist

Choosing to rebuild a failed pump or replace it depends on: age of machine, remaining useful life, cost differential, and time sensitivity.

- Rebuild if the machine has many remaining hours, original housing is sound, and skilled reman service is available.

- Replace with new OEM or High Quality aftermarket if uptime is critical, long warranty is desired, or the system has had multiple prior rebuilds.

- Use rebuilt units for interim repairs where budget or lead time prevents new-purchase.

Illustrative example: TCO scenario for a single CAT 336D pump over 5 years

The table below is an illustrative scenario (example numbers) to show how initial cost, maintenance, and downtime interplay. Use your fleet data to replace assumptions.

| Item | OEM New | High Quality Aftermarket | Rebuilt |

|---|---|---|---|

| Initial purchase price | $12,000 | $8,000 | $4,500 |

| Average annual maintenance & fluids | $800 | $900 | $1,200 |

| Warranty period | 24 months | 12 months | 6–12 months |

| Expected unplanned downtime events (5 yrs) | 0–1 | 1–2 | 2–3 |

| Estimated downtime cost (5 yrs) | $2,000 | $4,500 | $9,000 |

| Total estimated 5-year TCO | $18,000 | $17,300 | $18,700 |

Notes: These are sample figures to demonstrate calculation methodology and relative trade-offs. Real values will depend on fleet operating profile, availability of parts, and supplier warranties. The High Quality aftermarket option can be competitive on TCO when reliability and warranty are strong.

Brand and supplier considerations — why the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement can be a smart choice

When buying for a CAT 336D fleet, consider suppliers who offer:

- Transparent test reports (flow, pressure, efficiency curves)

- Clear fitment validation and part-number cross reference

- Responsive global shipping and technical support

- Options for OEM, High Quality aftermarket, and reman so you can adopt a mixed procurement strategy

Our 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement is designed to meet these needs: direct fit, high-pressure performance, and quality testing. Choosing a supplier with documented quality control and responsive support reduces administrative friction and accelerates repair times — directly improving TCO.

Practical procurement rules for fleet managers

- Track actual downtime and maintenance costs per machine — good data beats guesswork.

- Standardize part numbers across similar fleet models to reduce inventory SKUs and improve buy-bulk pricing.

- Negotiate multi-unit discounts and service-level commitments (RMA turnaround, advance exchange).

- Require supplier test certificates and warranty terms in writing.

- Use condition monitoring so you can plan replacements during scheduled downtime windows.

FAQs — Excavator hydraulic pump TCO and the 336D replacement

Q: How often should the hydraulic pump on a CAT 336D be replaced?

A: There is no fixed interval — replacement is condition-driven. With good maintenance and clean fluids, a pump can last several thousand operating hours. Monitor flow, pressure, temperature, and oil cleanliness for signs of wear.

Q: Is it safer to buy OEM or aftermarket for my 336D pump?

A: OEM is the safest for guaranteed fit, documented performance, and longer warranty. High-quality aftermarket options can offer near-OEM performance at lower cost; evaluate supplier test data and warranty terms.

Q: Can a rebuild be as reliable as a new pump?

A: A professional rebuild with thorough inspection, replacement of wear parts, and testing can be highly reliable — especially when the original housing is in good condition. Warranty and reman quality vary widely; select experienced remanufacturers.

Q: How do I minimize downtime when replacing a pump?

A: Keep a stocked inventory of commonly used pumps, train technicians for rapid swap and system flush procedures, and consider advance-exchange programs from suppliers to reduce repair turnaround.

Q: What is the most important maintenance action to extend pump life?

A: Maintain fluid cleanliness and proper filtration. Contamination is the leading cause of hydraulic pump wear. Regular oil analysis and timely filter changes will extend pump life significantly.

Call to action — get the right pump and reduce your fleet TCO

If you manage CAT 336D equipment and want a robust, tested replacement, the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement is designed for direct fit, heavy-duty performance, and global support. Contact our parts team to request a quote, test documentation, and lead times — or view the product page to compare OEM and High Quality aftermarket options. Reach out now to schedule an assessment of your fleet's hydraulic pump TCO and an optimized procurement plan.

Authoritative references and further reading

- Hydraulic pump — Wikipedia

- Caterpillar — Official site (equipment and parts)

- ISO 4406:2017 — Hydraulic fluid power — Fluid contamination

- Hydraulics & Pneumatics — Industry articles and best practices

- Construction Equipment — Industry news and maintenance insights

Contact / View product

To request a quote or technical datasheet for the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement, contact our sales team or visit the product page. Our specialists can provide cross-references, warranty details, and guidance on whether OEM, High Quality aftermarket, or rebuilt units best match your fleet strategy.

Choosing an Original Hitachi Engine Supplier: ZAX870-5G Guide

Top Suppliers of High-Quality Excavator Parts in 2025: A Buyer's Guide

Comparing OEM engine assemblies vs aftermarket options

Top 10 excavator parts Manufacturers and Supplier Brands

FAQ

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -