jackhuang5919@gmail.com

Warranty, Testing and Quality Controls for Isuzu D1703

- Warranty, Testing and Quality Controls for Isuzu D1703

- Overview: Engineered Diesel Reliability in the Isuzu D1703

- Manufacturing Quality Controls: From Casting to Final Assembly

- End-of-Line Testing: What You Should Expect

- Laboratory and Dynamometer Tests: Performance and Durability

- Emissions and Regulatory Compliance Testing

- Component-Level Quality: Fuel Systems, Turbochargers, and Cooling

- Warranty Structures: What Is Typical and What to Watch For

- Certified Remanufactured and Aftermarket Engines: Quality and Warranty Differences

- Incoming Inspection Checklist for Buyers and Installers

- Maintenance Practices that Preserve Warranty and Longevity

- How Manufacturers and Vendors Handle Warranty Claims

- Verifying Quality: What Documentation to Request

- Brand Assurance: Why Choose Isuzu and Certified Suppliers

- FAQ — Frequently Asked Questions

- Contact Us / View Product

- Authoritative References

Warranty, Testing and Quality Controls for Isuzu D1703

Overview: Engineered Diesel Reliability in the Isuzu D1703

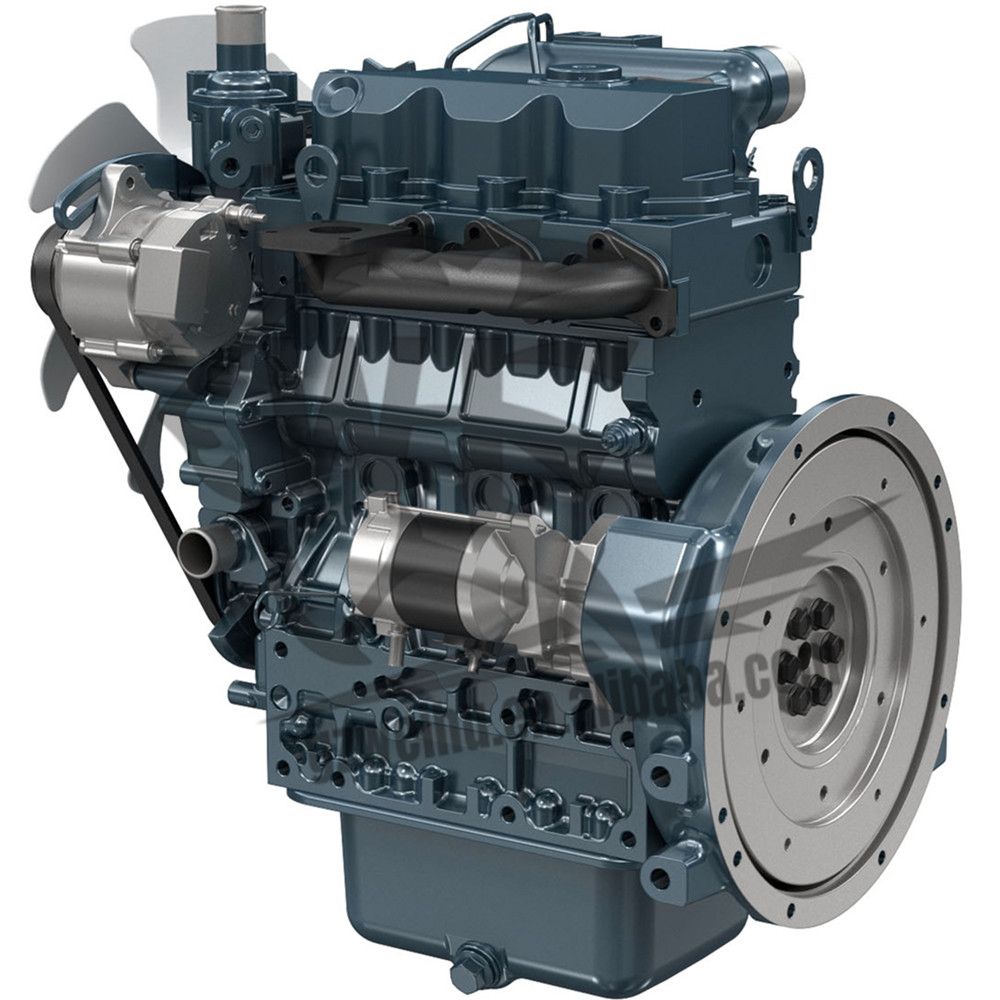

The Isuzu D1703 Diesel Engine | High-Performance Engine Assembly for Heavy Machinery is an engineered diesel solution built to deliver dependable power for excavators, construction equipment, and industrial applications. When selecting or supporting a heavy‑duty engine like the D1703, understanding warranty coverage, factory testing, and quality control processes is essential to reduce downtime, manage lifecycle costs, and ensure safe operation. This article explains the quality systems and tests commonly applied to modern diesel engines, how warranties are structured, and practical steps fleet managers and buyers should take to validate and protect their investment.

Manufacturing Quality Controls: From Casting to Final Assembly

High-quality engine production begins upstream at parts manufacturing and continues through assembly and final inspection. For an engineered diesel such as the Isuzu D1703, manufacturers typically implement documented quality management systems (for example, ISO 9001) that control processes including raw-material inspection, machining tolerances, heat treatment, surface finish, and assembly torque specifications. Key quality-control checkpoints include:

- Incoming material inspection — verifying metallurgy and dimensions.

- Component-level testing — pressure tests for cylinder heads, non-destructive testing (NDT) for critical castings.

- Sub-assembly verification — valve train timing, fuel pump calibration, turbocharger balancing.

- Final assembly checks — clearance measurements, torque audits, and leak tests.

Commercial-intent keyword: engineered diesel quality assurance.

End-of-Line Testing: What You Should Expect

End-of-line (EOL) testing validates that the assembled engine meets performance and safety targets before shipment. Typical EOL tests for an Isuzu D1703‑class engine include:

- Cold start and warm-up sequences to detect abnormal sounds or oil/coolant leaks.

- Leak-down and compression tests to verify sealing and cylinder integrity.

- Basic dyno runs or simulated-load testing to confirm power output, torque curve behavior, and fuel consumption within expected tolerances.

- Emissions verification where applicable to ensure compliance with regulatory limits (e.g., nonroad diesel regulations).

These tests are designed to catch assembly issues, sensor mis-calibrations, and early-life defects. Commercial-intent keyword: Isuzu D1703 diesel engine final testing.

Laboratory and Dynamometer Tests: Performance and Durability

Beyond EOL checks, engineered diesel engines undergo laboratory dyno and durability testing during development and production control. These controlled tests simulate extended use and harsh operating conditions to reveal wear modes and confirm durability limits:

- Performance mapping on engine dynamometers to produce torque and power curves at various speeds and loads (standards such as SAE J1349 or ISO 3046 are commonly referenced for reporting performance).

- Endurance runs that accumulate hundreds to thousands of hours on test rigs to evaluate component life, oil consumption, and thermal behavior.

- Transient testing to assess response during load changes—important for construction equipment duty cycles.

Including such testing in product development helps manufacturers deliver an engineered diesel product that balances power, fuel efficiency, and longevity. Commercial-intent keyword: Isuzu D1703 engineered diesel performance testing.

Emissions and Regulatory Compliance Testing

Modern diesel engines must meet regional emissions regulations (EPA, EU Stage, etc.). Compliance testing typically involves certified labs and standardized cycles that measure NOx, PM, CO, and HC under specified loads and temperatures. For nonroad engines used in excavators and construction equipment, manufacturers certify engines to nonroad emissions standards, and appropriate documentation should accompany each engine shipped to regulated markets.

For buyers and fleet managers: always request emissions certification and any compliance certificates relevant to your jurisdiction before purchase or installation. Commercial-intent keyword: emissions-tested engineered diesel.

Component-Level Quality: Fuel Systems, Turbochargers, and Cooling

Major subsystems contribute disproportionately to engine reliability. Common quality-control measures include:

- Fuel system calibration and leak testing — precision calibration of injectors and pumps reduces fuel-related failures and emissions variances.

- Turbocharger balancing and shaft-play checks — prevents premature bearing failure and vibration issues.

- Cooling-system pressure tests and flow verification — critical for preventing overheating in heavy-duty duty cycles.

When evaluating a D1703 or replacement assembly, ask for component traceability records and any batch testing certificates for high-risk parts. Commercial-intent keyword: Isuzu D1703 fuel system testing.

Warranty Structures: What Is Typical and What to Watch For

Warranty terms for heavy‑duty diesel engines vary by manufacturer and distributor, but they typically cover defects in materials and workmanship for a defined period or number of operating hours—whichever comes first. Common elements you should verify include:

- Duration and limits — examples include 12–24 months or a specific hourly limit (e.g., 1,000–2,000 hours) for nonroad engines — always confirm exact terms for the D1703 from the selling party.

- Coverage scope — whether it is full replacement, prorated, or limited to certain components (e.g., turbocharger, cylinder head, injectors).

- Exclusions — typical exclusions include misuse, improper maintenance, use of non‑approved lubricants or fuels, and unauthorized modifications.

- Claims process and required documentation — registration, maintenance logs, and proof of compliant installation are often prerequisites for a claim.

Pro tip: maintain a detailed service log from day one and follow OEM-recommended service intervals to preserve warranty eligibility. Commercial-intent keyword: Isuzu D1703 warranty terms.

Certified Remanufactured and Aftermarket Engines: Quality and Warranty Differences

Remanufactured or reconditioned D1703 engines can offer cost savings, but quality and warranty vary by provider. Certified remanufacturers typically disassemble the core, replace wear items to OEM standards, re-machine critical surfaces, and perform dyno testing. Compare these factors when choosing between new, remanufactured, or aftermarket options:

| Option | Typical Warranty | Testing & Quality Controls | Cost Consideration |

|---|---|---|---|

| New OEM Engine | Manufacturer warranty (parts & labor) — varies | Full factory testing, certified assembly, emissions certs | Highest initial cost, lowest risk |

| Certified Remanufactured | Remanufacturer warranty (limited duration) | Complete rebuild, end-of-line dyno tests (varies by vendor) | Lower cost, moderate risk if vendor certified |

| Aftermarket/New-Old-Stock | Limited or no warranty (depends on supplier) | Variable testing; may lack comprehensive dyno validation | Lowest cost, higher operational risk |

Always request written test reports and warranty terms before purchase. Commercial-intent keyword: Isuzu D1703 remanufactured warranty.

Incoming Inspection Checklist for Buyers and Installers

When you receive an Isuzu D1703 or an assembly claiming to be factory-tested, perform the following incoming checks to protect your investment and establish a baseline for warranty claims:

- Visual inspection for shipping damage, loose fittings, or missing parts.

- Verify serial numbers and labels against purchase documentation and emissions certificates.

- Ask for completed EOL test sheet / dyno report and check recorded hours on any test run.

- Confirm that consumables (oil, filters, coolant) were filled with recommended products and documented if required by warranty.

- Document installation with photos and initial service entry in your maintenance system.

Commercial-intent keyword: Isuzu D1703 incoming inspection.

Maintenance Practices that Preserve Warranty and Longevity

Routine maintenance and use of approved fluids and filters are often contractual requirements for warranty eligibility. Best practices include:

- Follow OEM service intervals for oil and filter changes.

- Use fuels and lubricants that meet manufacturer specifications.

- Monitor operating parameters (oil pressure, temperatures, exhaust behavior) and respond promptly to alarms.

- Keep accurate maintenance records and log all repairs and parts replacements.

Adhering to these practices minimizes the risk of avoidable failures and strengthens warranty claims if a covered defect appears. Commercial-intent keyword: engineered diesel maintenance.

How Manufacturers and Vendors Handle Warranty Claims

When a potential warranty issue appears, vendors usually require a structured claims process. Steps typically include:

- Immediate notification with description, serial number, and operating history.

- Submission of maintenance records and installation documentation.

- Initial inspection (remote troubleshooting or local dealer visit) to determine if the issue falls under warranty.

- If approved, repair/replacement per warranty terms; if denied, vendor provides a report explaining exclusions.

To streamline claims, keep photographic evidence, machine-hours logs, fuel quality records, and details of any external events (overheating, contamination) that might influence the decision. Commercial-intent keyword: Isuzu D1703 warranty claim process.

Verifying Quality: What Documentation to Request

For traceability and audit purposes, the following documents are valuable when buying an engine or assembly:

- Bill of materials and serial number list.

- End-of-line test reports and dyno graphs.

- Emissions certification and compliance statements.

- ISO or equivalent quality management certificates for the manufacturing site.

- Warranty policy and claim procedure documents.

Receiving complete documentation at delivery reduces ambiguity and protects both buyer and seller. Commercial-intent keyword: Isuzu D1703 quality documentation.

Brand Assurance: Why Choose Isuzu and Certified Suppliers

Isuzu has a long-standing reputation in commercial diesel engines for reliability and global service support. When combined with certified manufacturing and rigorous testing, the Isuzu D1703 Diesel Engine | High-Performance Engine Assembly for Heavy Machinery provides a strong balance of performance and lifecycle support. Choosing OEM or certified reman suppliers helps ensure consistent quality controls, traceability, and a clearer warranty path.

Commercial-intent keyword: Isuzu D1703 brand assurance engineered diesel.

FAQ — Frequently Asked Questions

Q1: What is typically covered under an Isuzu D1703 engine warranty?

A: Coverage usually includes defects in materials and workmanship for a specified time period or operating-hour limit. Coverage details (component exclusions, claim procedures) vary by seller—always review the written warranty provided at sale.

Q2: How can I confirm that a D1703 has passed factory testing?

A: Request the end-of-line test report, dyno graphs, and any emissions certification. Verify serial numbers and test-stamp evidence against the paperwork on delivery.

Q3: Are remanufactured D1703 engines reliable?

A: Certified remanufactured engines can be reliable if rebuilt to OEM tolerances and dyno-tested. Check the remanufacturer’s accreditation, warranty, and test documentation.

Q4: What maintenance will void a warranty?

A: Using non‑approved fuels or lubricants, missing scheduled maintenance, unauthorized modifications, or evidence of neglect/abuse are common grounds for denial of warranty claims.

Q5: Which tests are most important for heavy‑duty excavator applications?

A: Endurance/durability runs, transient response testing, and cooling-system verification are crucial because excavator duty cycles include frequent load changes and potential overheating risks.

Contact Us / View Product

With quality and warranty protections in place, operators can confidently move forward with upgrading heavy equipment with engineered diesel solutions.If you are considering the Isuzu D1703 Diesel Engine | High-Performance Engine Assembly for Heavy Machinery or need assistance validating test documentation and warranty coverage, contact our sales and technical team. We provide pre-delivery inspection services, certified reman options, and extended warranty packages to match your fleet's operational needs.

Authoritative References

- ISO — ISO 3046 series: Performance of internal combustion engines (https://www.iso.org/standard/38110.)

- SAE International — Engine power standards (SAE J1349) (https://www.sae.org/)

- United States Environmental Protection Agency (EPA) — Nonroad diesel engine regulations (https://www.epa.gov/regulations-emissions-vehicles-and-engines/regulations-emissions-nonroad-diesel-engines)

- Isuzu Motors — Corporate & product information (https://www.isuzu.com/)

- ISO — Quality management systems (ISO 9001) (https://www.iso.org/iso-9001-quality-management.)

- SAE International & industry guidance on durability and testing best practices (https://www.sae.org/)

- Wikipedia — Isuzu Motors overview (https://en.wikipedia.org/wiki/Isuzu_Motors)

Note: Specific warranty durations, hourly limits, and detailed test results for the Isuzu D1703 should be confirmed with the selling dealer or the official manufacturer documentation at the time of purchase.

Comparing OEM engine assemblies vs aftermarket options

Buyer's Guide: Choosing a Hydraulic Hydraulic Pump for Excavators

Selecting the right engine assemblies for heavy excavators

Top 5 excavator engine Company List and Products Compared

FAQ

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -