jackhuang5919@gmail.com

Supply Chain Risks and Lead Time Strategies for Pump Procurement

- Supply Chain Risks and Lead Time Strategies for Pump Procurement

- Why supply chain risk matters for hydraulic pump procurement

- Product snapshot: 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- Common supply chain risks impacting hydraulic pump procurement

- How lead time is composed for a hydraulic pump order

- OEM vs aftermarket: lead time, cost, and quality comparison

- Practical lead time reduction strategies for procurement teams

- Quick calculation example: reorder point for a 336D pump

- Quality assurance and inspection to avoid downstream delays

- When to choose remanufactured or aftermarket pumps

- Contracting and commercial levers to secure lead times

- Brand advantage: why choose our 336D Excavator Hydraulic Pump offerings

- Case study snapshot: reducing downtime through a two-source strategy

- Practical checklist before placing a pump order

- Frequently Asked Questions (FAQ)

- Q: How long does it take to get a 336D Excavator Hydraulic Pump?

- Q: Is an aftermarket or remanufactured pump safe to use on CAT equipment?

- Q: What should I do when I need a pump urgently?

- Q: Can we reduce lead time without increasing inventory holding too much?

- Q: What warranty coverage should I expect?

- Contact us / View product

- Authoritative references and further reading

Supply Chain Risks and Lead Time Strategies for Pump Procurement

Why supply chain risk matters for hydraulic pump procurement

Hydraulic systems are mission-critical on heavy equipment. When a hydraulic hydraulic pump fails, equipment downtime quickly turns into lost productivity and higher operating costs. Procurement teams therefore must understand the supply chain risks that affect availability, lead times, and total cost of ownership for parts like the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement. This article explains the main risks, shows practical strategies to reduce lead times, compares OEM and aftermarket choices, and gives procurement-ready tactics you can apply immediately.

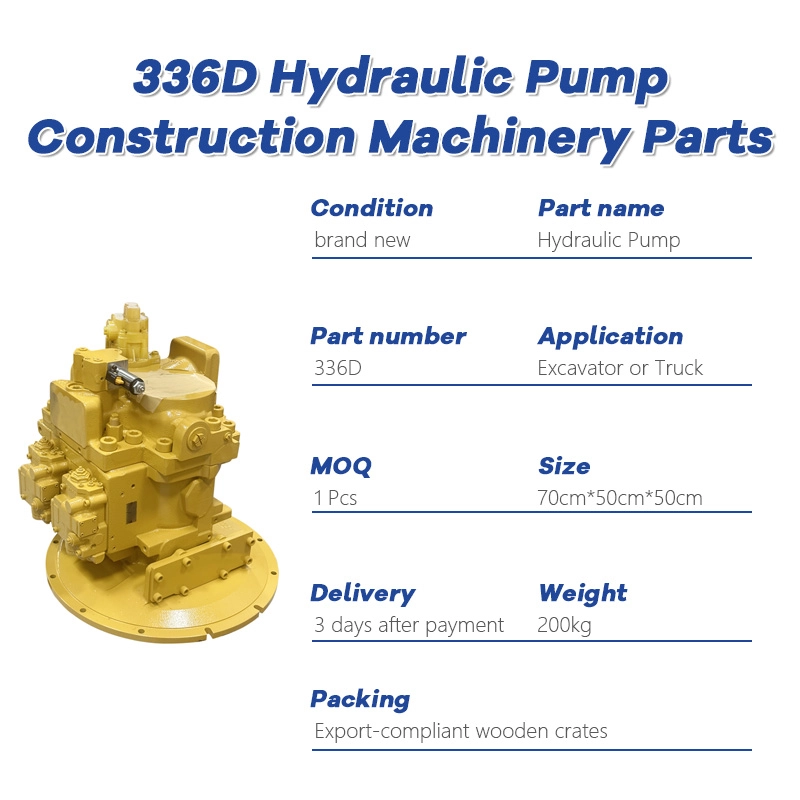

Product snapshot: 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Common supply chain risks impacting hydraulic pump procurement

Understanding risk categories helps you design controls and contingencies. Key risks for hydraulic pumps include:

- Supplier concentration and single-source risk: Relying on one vendor increases exposure to factory shutdowns, quality problems, or financial failure.

- Raw material and component shortages: Pumps require machined steel, precision bearings, seals, and often electronic sensors. Disruptions in steel, specialty elastomers, or semiconductors can delay production.

- Transportation and logistics delays: Port congestion, container shortages, and carrier rate volatility lengthen transit time and increase unpredictability.

- Geopolitical and regulatory risks: Trade restrictions, tariffs, or export controls can block parts or change costs suddenly.

- Quality and counterfeits: Low-quality or counterfeit components create rework, warranty issues, and safety risks.

- Demand volatility and forecasting error: Construction cycles and fleet changes can spike demand unexpectedly, exposing insufficient inventory policies.

How lead time is composed for a hydraulic pump order

Lead time commonly includes order processing, manufacturing, quality inspection, inland transport to port, ocean/air transit, customs clearance, and domestic delivery. For a heavy-duty CAT replacement pump such as the 336D Excavator Hydraulic Pump, a typical breakdown might look like this:

| Stage | Typical time (days) |

|---|---|

| Order processing and material allocation | 2-7 |

| Manufacturing or remanufacturing | 7-30 |

| Quality testing and inspection | 1-5 |

| Domestic transport to port | 1-7 |

| International transit (ocean) | 14-45 |

| Customs and inbound logistics | 2-10 |

| Last-mile delivery | 1-7 |

| Total typical lead time | 28-111 days |

The ranges are wide because some customers choose air freight, local stock, or remanufactured cores which shorten lead times, while others rely on offshore production that increases transit time.

OEM vs aftermarket: lead time, cost, and quality comparison

Deciding between OEM and aftermarket affects lead time, warranty, and lifecycle costs. The table below summarizes typical differences for pumps like the CAT 336D replacement:

| Aspect | OEM | High-quality aftermarket / reman |

|---|---|---|

| Typical lead time | 30-90 days if made-to-order or shipped from dealer stock | 7-30 days for established remanufacturers or stocked aftermarket lines |

| Unit price | Higher initial cost | Lower to moderate |

| Warranty | Longer OEM-backed warranty | Good warranty but varies by supplier |

| Parts traceability & specs | Full OEM traceability | Depends on quality controls |

| Availability in emergencies | Can be limited if dealer stock is low | Often faster if local reman or distributor stocks units |

Practical lead time reduction strategies for procurement teams

Here are proven tactics procurement and maintenance teams can apply to reduce downtime and improve supply certainty for hydraulic pump procurement:

- Hold critical spares (safety stock): Maintain at least 1-2 pumps per critical machine cluster or rotating inventory based on mean time between failures (MTBF).

- Diversify suppliers: Contract with both OEM dealers and certified aftermarket/remanufacturers to avoid single-source exposure.

- Stock locally or use consignment: Arrange consignment inventory at major depots or customer sites so parts are available on demand.

- Use expedited logistics selectively: For emergency repairs, air freight or top-tier carriers can cut transit time but at a High Quality. Use only when downtime cost justifies expense.

- Pre-qualify remanufacturers: Establish approved vendor lists (AVLs) with quality audits to fast-track aftermarket replacements when needed.

- Enter long-term agreements: Framework contracts with defined lead times, volume commitments, and penalties reduce variability and secure priority production slots.

- Implement predictive maintenance: Use vibration, temperature, and flow analytics to forecast pump failure weeks or months ahead and order replacements proactively.

- Optimize reorder point calculations: Use actual usage rates, supplier lead time variability, and service level targets to compute reorder points and reorder quantities (EOQ or continuous review models).

Quick calculation example: reorder point for a 336D pump

Assume fleet failure rate requires 4 pumps per year, average lead time 45 days, safety stock for 30-day coverage, and 365 days/year. Reorder point (units) = daily usage * lead time + safety stock.

- Daily usage = 4 / 365 = 0.011 pumps/day

- Lead time demand = 0.011 * 45 ≈ 0.5 pumps

- Safety stock demand (30 days) = 0.011 * 30 ≈ 0.33 pumps

- Reorder point ≈ 0.5 + 0.33 = 0.83 → maintain 1 pump available before ordering

This simple model shows why many fleets keep at least one spare pump per critical machine or have rapid access to a nearby reman supplier.

Quality assurance and inspection to avoid downstream delays

Receiving a defective pump causes rework, returns, and extended downtime. To prevent this:

- Inspect units on arrival against OEM specifications and serial numbers.

- Require test reports and torque/flow curves for remanufactured units.

- Adopt incoming quality checks and a non-conformance process with agreed return windows.

- Use asset tagging and traceability to ensure warranty coverage and support claim processing.

When to choose remanufactured or aftermarket pumps

Remanufactured pumps can offer faster availability and lower cost while providing performance comparable to OEM when sourced from reputable vendors. Choose aftermarket/reman when:

- Downtime cost outweighs incremental risk of non-OEM parts

- Supplier provides test certificates, warranty, and traceability

- Local supplier can deliver rapidly and offers technical support

Keep OEM as an option where full traceability, long-term warranty, or specific calibration is required.

Contracting and commercial levers to secure lead times

Procurement can use several contractual mechanisms to reduce supply risk:

- Priority allocation clauses that give you earlier access during shortages

- Fixed lead time SLAs with liquidated damages for missed delivery

- Consignment or vendor-managed inventory to shift stockholding to the supplier while ensuring immediate availability

- Forecast sharing and collaborative planning to help suppliers plan capacity

- Frame agreements with multiple geographical sources to mitigate regional disruptions

Brand advantage: why choose our 336D Excavator Hydraulic Pump offerings

We provide both OEM-equivalent and High Quality aftermarket 336D Excavator Hydraulic Pump options designed to reduce procurement risk and shorten downtime. Our advantages include:

- Global inventory and expedited shipping options to reduce transit time

- Certified remanufacturing partners with documented testing and traceability

- Flexible commercial terms including consignment, standing orders, and priority fulfillment

- Technical support from experienced hydraulic engineers to help with diagnostics and installation

- Competitive warranties that protect your service costs

Case study snapshot: reducing downtime through a two-source strategy

A medium-size contractor operating 10 CAT 336D excavators used to wait 60+ days for OEM pumps during peak season. After implementing a two-source strategy (one local reman supplier + OEM backup) and holding one spare pump per three machines, mean downtime per pump failure dropped from 12 days to 2.5 days. The total annual replacement cost decreased by 18% due to fewer emergency transports and less idle equipment.

Practical checklist before placing a pump order

- Confirm machine serial and exact pump model to avoid misordering

- Decide OEM vs reman based on urgency, warranty needs, and cost

- Check supplier lead times and current inventory status

- Request test certificates and warranty terms for remanufactured units

- Arrange expedited logistics if downtime cost justifies

- Plan installation window and personnel availability to avoid bench time

Frequently Asked Questions (FAQ)

Q: How long does it take to get a 336D Excavator Hydraulic Pump?

A: Typical total lead time ranges from 7 days (local stocked reman or expedited shipping) to 90+ days (custom OEM orders with standard ocean freight). The exact time depends on stock, supplier location, and selected shipping method.

Q: Is an aftermarket or remanufactured pump safe to use on CAT equipment?

A: High-quality remanufactured pumps from certified vendors are safe and perform comparably to OEM when they include proper testing and warranties. Always verify vendor certifications and ask for test reports and warranty terms.

Q: What should I do when I need a pump urgently?

A: Use a prioritized plan: confirm the exact pump part number, contact pre-approved reman suppliers for local stock, consider air freight if needed, and prepare installation resources in advance to minimize bench time.

Q: Can we reduce lead time without increasing inventory holding too much?

A: Yes — options include consignment inventory, vendor-managed inventory, framework agreements with guaranteed lead times, and predictive maintenance to order parts before failure.

Q: What warranty coverage should I expect?

A: OEM pumps typically include manufacturer warranties; reputable remanufacturers offer warranties that vary by provider. Always request warranty terms in writing and keep proof of installation and testing.

Contact us / View product

Supply reliability must be supported by documented quality assurance. Reviewing warranty, certifications and quality standards for heavy duty pumps protects buyers from compliance and liability issues.If you need fast replacements or a procurement plan for your fleet, contact our sales team to check current stock, lead times, and consignment options for the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement. We also provide technical guidance to match the right pump to your machine and operational needs.

View product details and request a quote for the 336D Excavator Hydraulic Pump

Authoritative references and further reading

- Manufacturers and OEM guidance: https://www.cat.com

- Hydraulic system basics (Wikipedia): https://en.wikipedia.org/wiki/Hydraulics

- Supply chain risk management concepts (ISO and frameworks): https://www.iso.org

- Logistics and shipping insights: https://www.worldshipping.org

- Standards for pumps and rotating equipment: https://www.pumps.org (Hydraulic Institute)

Maintenance Contracts vs Parts Replacement: Procurement Considerations

How to Choose the Right Excavator Engine for Your Construction Equipment

Integration Guide: Installing SY550 6WG1 into Existing Fleets

How SY550 6WG1 Improves Uptime and Maintenance Efficiency

FAQ

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -