jackhuang5919@gmail.com

Warranty, Certifications and Quality Standards for Heavy Duty Pumps

- Warranty, Certifications and Quality Standards for Heavy Duty Pumps — 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- Understanding coverage for your hydraulic hydraulic pump: Warranty basics for the 336D Excavator Hydraulic Pump

- What a robust warranty should include — : buy with warranty confidence

- Certifications that matter for heavy duty hydraulic pumps: Ensuring compliance and reliability

- Key industry and quality certifications for hydraulic pumps

- Testing and third-party validation — commercial reassurance for your investment

- Quality standards and manufacturing controls for heavy duty pumps: From casting to assembly

- Material selection and machining tolerances for a dependable hydraulic hydraulic pump

- Assembly controls, balancing and quality inspection — what to require

- OEM vs high-quality aftermarket: Comparing warranties, certifications and performance

- Side-by-side comparison of OEM and aftermarket 336D excavator hydraulic pumps

- Contamination control and maintenance standards that preserve warranty and performance

- Why hydraulic fluid cleanliness (hydraulic hydraulic pump health) matters

- Routine maintenance practices to protect warranties and extend service life

- Quality assurance testing: What to request before you buy a hydraulic pump

- Essential test reports and documentation to obtain

- Brand advantages: Why choose our 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- Combining warranty, certifications and proven performance

- How to make an informed purchase decision for your hydraulic hydraulic pump

- Checklist before buying a replacement pump for a 336D Excavator

- Frequently Asked Questions (FAQs)

- Q: What does the warranty for the 336D Excavator Hydraulic Pump typically cover?

- Q: Are aftermarket hydraulic pumps as reliable as OEM pumps for the 336D?

- Q: How does fluid cleanliness affect my pump warranty?

- Q: What documentation should I keep to support a warranty claim?

- Q: Can I get on-site support for pump replacement on my 336D excavator?

- Contact us / View product — CTA

- References and authoritative resources

Warranty, Certifications and Quality Standards for Heavy Duty Pumps — 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

Understanding coverage for your hydraulic hydraulic pump: Warranty basics for the 336D Excavator Hydraulic Pump

When you purchase a heavy duty hydraulic pump for a Caterpillar 336D excavator, understanding the warranty terms is the first defense against downtime and unexpected repair costs. Warranties for hydraulic pumps typically cover defects in materials and workmanship, and sometimes specific performance guarantees for a fixed time or operating-hours period. For the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement, warranties differ by whether you choose an OEM unit or a High Quality aftermarket replacement. OEM units from Caterpillar or authorized dealers often include a standardized parts warranty tied to the machine's serial and ownership records. High-quality aftermarket pumps commonly offer competitive limited warranties (for example: 12–24 months or a defined number of operating hours) that explicitly outline exclusions like contamination damage or improper installation.

What a robust warranty should include — : buy with warranty confidence

A strong warranty for a hydraulic hydraulic pump should clearly state: start date and duration, what is covered (parts, labor, return shipping), what is excluded (contamination, improper maintenance, misuse), claim procedures, and whether a remanufactured or replacement part is provided. For fleet operators and contractors who depend on a 336D Excavator Hydraulic Pump for continuous heavy-duty operations, pay attention to the turnaround time for warranty claims and whether on-site support is available. A warranty that requires authorized installation and documented maintenance is common — keep service records to preserve coverage.

Certifications that matter for heavy duty hydraulic pumps: Ensuring compliance and reliability

Key industry and quality certifications for hydraulic pumps

Certifications are evidence that a manufacturer adheres to recognized processes and performance benchmarks. Important certifications and standards for heavy duty hydraulic pumps include:

- ISO 9001 — Quality Management Systems: verifies consistent manufacturing and quality control processes.

- ISO 4406 — Hydraulic fluid cleanliness coding: crucial for fluid contamination control in hydraulic systems.

- SAE and industry test standards — performance and dimensional standards used in pump design and interchangeability.

- Manufacturer-specific approvals — e.g., Caterpillar or other machine OEM approvals for direct-fit replacement pumps.

When evaluating a pump for your 336D excavator, look for documentation or labeling that confirms these certifications. Certified suppliers reduce the risk of premature failures and often have tighter production tolerances and stronger process controls.

Testing and third-party validation — commercial reassurance for your investment

Beyond certificates, credible testing validates real-world performance. Typical tests include pressure and flow curve verification, endurance (run-to-failure or endurance cycles), contamination tolerance testing, and vibration/shock testing relevant to excavator environments. Third-party labs or OEM validation reports add an extra layer of confidence; companies that publish test data (or provide it upon request) are more likely to stand behind their products.

Quality standards and manufacturing controls for heavy duty pumps: From casting to assembly

Material selection and machining tolerances for a dependable hydraulic hydraulic pump

Durability of a heavy duty pump starts with raw materials and precision machining. Critical components — housing, rotors, shafts, and valve plates — must meet metallurgical specifications to resist wear, cavitation, and fatigue. Tighter machining tolerances reduce internal leakage and improve volumetric efficiency, which is essential for the high-pressure performance demanded by heavy excavator operations. Reputable manufacturers publish material data sheets and tolerance ranges for key dimensions; request these before purchasing replacement pumps for your 336D Excavator.

Assembly controls, balancing and quality inspection — what to require

Modern hydraulic pumps are assembled in controlled environments with documented process steps: component cleaning, precise press fits, dynamic balancing, and final bench testing. Quality inspection points commonly include surface finish checks, dimensional checks, leak testing, pressure and flow verification, and serial-number traceability. If a supplier cannot provide a traceable assembly and test report for each pump, consider it a risk for critical applications.

OEM vs high-quality aftermarket: Comparing warranties, certifications and performance

Side-by-side comparison of OEM and aftermarket 336D excavator hydraulic pumps

Choosing between OEM and aftermarket pumps involves trade-offs among cost, warranty scope, available certifications, and lead time. The table below highlights common differences to help commercial buyers make informed decisions when replacing or upgrading a 336D Excavator Hydraulic Pump.

| Factor | OEM (Caterpillar) | High-Quality Aftermarket |

|---|---|---|

| Warranty | Usually standardized, tied to dealer policies; often comprehensive | Competitive limited warranty (12–24 months common); details vary by brand |

| Certifications | OEM-approved; meets OEM specifications and fitment | ISO 9001 common; some brands obtain OEM-approval or equivalent testing |

| Price | Higher cost | Lower to mid cost depending on brand and tests |

| Parts availability | Through dealer networks; may have lead times | Often faster availability and global shipping options |

| Quality control | Strict OEM controls | Varies by manufacturer; best aftermarket brands offer rigorous QC and test reports |

High-quality aftermarket pumps can match or closely approach OEM performance and often offer better lead times and pricing — but verify warranty terms, test documentation, and return policies first.

Contamination control and maintenance standards that preserve warranty and performance

Why hydraulic fluid cleanliness (hydraulic hydraulic pump health) matters

Contamination is the number-one cause of hydraulic pump failure. Fine particles, water, and degraded fluids accelerate wear on critical surfaces. Standards such as ISO 4406 define contamination coding and acceptable cleanliness levels for hydraulic systems. Maintaining fluid cleanliness within recommended standards is often a condition of warranty coverage. For a 336D Excavator Hydraulic Pump, use recommended hydraulic fluids, follow filtration guidelines, and replace filters on schedule to reduce the risk of voided warranty claims.

Routine maintenance practices to protect warranties and extend service life

- Follow manufacturer-recommended service intervals and document each maintenance action.

- Use the correct fluid viscosity and specification for the 336D hydraulic system.

- Monitor filter indicators and replace hydraulic filters based on hours or differential pressure.

- Perform regular fluid sampling and particle counts; retain reports as part of warranty evidence.

- Ensure proper installation by trained technicians; many warranties require authorized or documented professional installation.

Quality assurance testing: What to request before you buy a hydraulic pump

Essential test reports and documentation to obtain

Ask suppliers for the following before purchase to validate quality claims:

- Individual serial-numbered test certificates (pressure/flow curves, leakage, vibration).

- Material certifications and heat-treatment records for critical parts.

- ISO 9001 certification copy and factory quality audit summaries.

- Contamination control procedures and cleanliness verification for shipped units.

- Warranty policy document and RMA/claim procedures.

Suppliers that provide these documents make it easier to handle claims, perform root cause analysis, and ensure faster resolution when problems occur.

Brand advantages: Why choose our 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

Combining warranty, certifications and proven performance

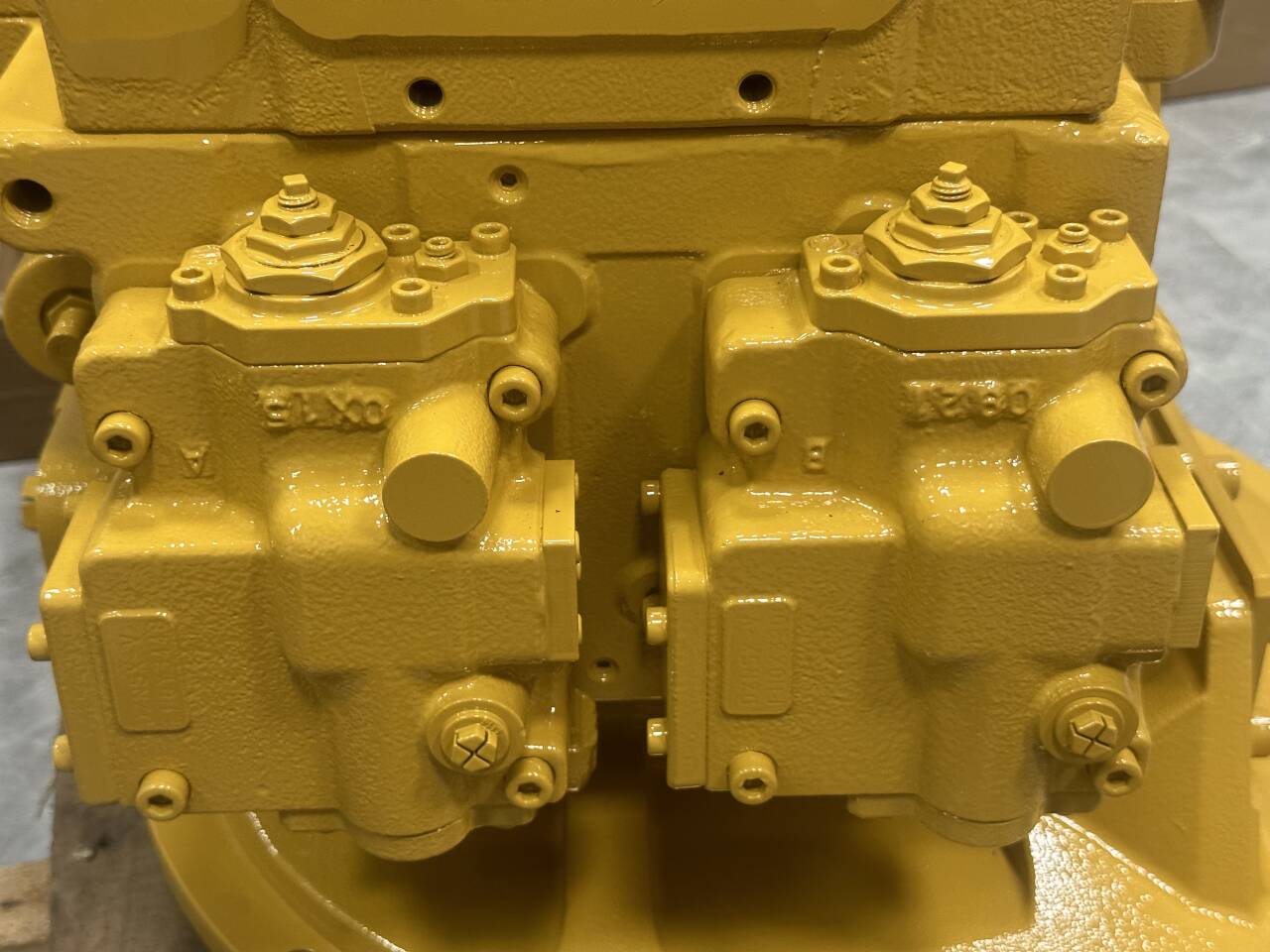

Our 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

We provide transparent warranty terms, documented test reports, and traceability for every pump. Our aftermarket pumps are manufactured under ISO 9001 systems and undergo strict bench testing to match OEM performance curves.

How to make an informed purchase decision for your hydraulic hydraulic pump

Checklist before buying a replacement pump for a 336D Excavator

Use this quick checklist to evaluate any replacement hydraulic pump:

- Verify fitment: confirm model compatibility with Caterpillar 336D serial numbers.

- Compare warranty scope and exclusions in writing.

- Request test certificates and ISO compliance documentation.

- Confirm return policy and RMA procedures.

- Plan installation by trained technicians and retain service records.

- Ask about lead times, support, and spare parts availability.

Frequently Asked Questions (FAQs)

Q: What does the warranty for the 336D Excavator Hydraulic Pump typically cover?

A: Warranties commonly cover defects in materials and workmanship for a stated period (often 12–24 months or a specified number of operating hours). Coverage usually excludes damage from contamination, improper installation, misuse, and normal wear. Always read the warranty document carefully.

Q: Are aftermarket hydraulic pumps as reliable as OEM pumps for the 336D?

A: High-quality aftermarket pumps can approach OEM reliability and cost less, but quality varies by manufacturer. Choose aftermarket pumps with ISO 9001 certification, documented test results, and a clear warranty to minimize risk.

Q: How does fluid cleanliness affect my pump warranty?

A: Contamination is a leading cause of hydraulic pump failure. Many warranties exclude damage from contaminated fluids. Adhering to ISO 4406 cleanliness levels and documenting fluid sampling and filter changes helps preserve warranty coverage.

Q: What documentation should I keep to support a warranty claim?

A: Keep purchase invoices, serial numbers, installation records, maintenance logs, filter-change records, and fluid sample reports. These documents prove proper use and maintenance if a warranty claim arises.

Q: Can I get on-site support for pump replacement on my 336D excavator?

A: Many suppliers and authorized dealers offer on-site installation or can recommend certified service centers. Confirm availability and costs before purchase.

Contact us / View product — CTA

Ready to secure a reliable replacement? View the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement product page or contact our sales team for warranty details, test reports, and availability. Our specialists will help you choose OEM or High Quality aftermarket options and arrange global shipping and installation support. With quality standards confirmed, organizations must choose how to support equipment long term. Comparing maintenance contracts vs parts replacement: procurement considerations helps define the most cost-effective support model.

References and authoritative resources

For industry standards and background reading, see the following authoritative sources:

- Hydraulic pump overview — Wikipedia: https://en.wikipedia.org/wiki/Hydraulic_pump

- ISO 9001 — Quality management systems — ISO: https://www.iso.org/iso-9001-quality-management.

- ISO 4406 — Hydraulic fluid contamination (information): https://en.wikipedia.org/wiki/ISO_4406

- Caterpillar official site — Excavators and parts: https://www.cat.com

- Society of Automotive Engineers (SAE) — Standards and technical information: https://www.sae.org

- Parker Hannifin — Hydraulics technical resources: https://www.parker.com

If you need the full test documentation or a customized quote for your Caterpillar 336D excavator, contact our parts team and provide your machine serial number for accurate fitment and warranty information.

Performance Under Load: Isuzu D1703 Engineered Diesel Review

Top 10 excavator spare parts Manufacturers and Supplier Brands

Excavator Engine Replacement: When and How

Best Practices for Maintaining Your Excavator Engine for Maximum Longevity

FAQ

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -