jackhuang5919@gmail.com

Selecting the Right Hydraulic Pump for CAT 336D Excavators

- Understanding Hydraulic Pump Basics and Why It Matters

- What a hydraulic pump does in a 336D

- Key performance parameters you must check

- Common pump types for heavy excavators

- Match Pump Specs to 336D Hydraulic System Requirements

- Displacement, flow and engine rpm: simple sizing rules

- Pressure rating and safety margins

- Compatibility: shaft, mounting, controls and electronics

- OEM vs High Quality Aftermarket: Choosing Between Authentic and High-Quality Replacements

- Direct comparison: what changes between OEM and aftermarket?

- Cost, lead time, and total life-cycle value

- Side-by-side spec comparison

- Practical Reliability Factors: Filtration, Fluid, and Maintenance

- Hydraulic fluid cleanliness and filtration

- Seal materials, temperature, and fluid compatibility

- Predictive maintenance and diagnostics

- Installation, Testing, and Field Commissioning Best Practices

- Pre-installation checklist

- Initial bench and field testing

- Troubleshooting common startup issues

- 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement (Product Highlight)

- References and further reading

- Frequently Asked Questions (FAQ)

- How do I know whether my CAT 336D needs a pump replacement or repair?

- Can I use an aftermarket pump in my 336D without problems?

- What filtration level should I maintain to protect a new hydraulic pump?

- How important is it to match the pump to the excavator's serial or model year?

- What maintenance steps extend the life of a hydraulic pump?

- Contact / View Product

Selecting the correct hydraulic pump for a CAT 336D excavator is a high-impact decision for fleet managers, maintenance technicians, and equipment owners. The right pump optimizes digging power, hydraulic responsiveness, and fuel efficiency while reducing downtime and life-cycle cost. This guide provides practical, actionable advice on pump selection—covering pump type, displacement, pressure rating, mounting and shaft compatibility, filtration and contamination control, testing and installation best practices—so you can choose a durable, reliable hydraulic pump that fits your operational needs.

Understanding Hydraulic Pump Basics and Why It Matters

What a hydraulic pump does in a 336D

A hydraulic pump converts mechanical power from the engine into hydraulic energy—producing flow (volume) and pressure that drive actuators, swing motors, and other hydraulic components. For the CAT 336D, the pump must supply adequate flow at the correct system pressure to achieve rated digging forces, smooth control, and efficient cycle times. For a technical overview, see the Hydraulic pump (Wikipedia).

Key performance parameters you must check

When selecting a hydraulic pump, evaluate these core specifications: displacement (cc/rev), maximum pressure rating (bar or psi), nominal flow at operating rpm (L/min or GPM), volumetric and mechanical efficiency, and shaft/mounting interface. These parameters determine whether the pump will deliver the required power without overheating, cavitation, or premature wear.

Common pump types for heavy excavators

Caterpillar excavators like the 336D typically use axial piston pumps (variable or fixed displacement) because they offer high pressure capability and efficiency. Gear pumps are more common in auxiliary circuits. Understanding the difference—axial piston pumps for primary work functions versus gear/ vane pumps for pilot or charge circuits—helps match the right component to the hydraulic circuit.

Match Pump Specs to 336D Hydraulic System Requirements

Displacement, flow and engine rpm: simple sizing rules

Select a pump displacement that delivers the desired flow at the engine rpm where the machine operates most often. Use the basic relation: Flow = Displacement × RPM. For example, if a pump has 120 cc/rev and the engine-driven pump shaft runs at 1,500 rpm, theoretical flow = 120 cc/rev × 1,500 rev/min = 180,000 cc/min = 180 L/min (minus losses). Consider volumetric efficiency (usually 85–95%) when calculating expected flow under load.

Pressure rating and safety margins

Verify the pump's maximum pressure rating exceeds the 336D system working pressure plus transient spikes. Pumps rated for at least 10–20% above the maximum system pressure reduce the risk of cavitation-related damage and extend seal life. Always coordinate with system relief valve settings and manufacturer specifications.

Compatibility: shaft, mounting, controls and electronics

Confirm physical fit: mounting pattern, shaft diameter and keyway, flange orientation, and coupler type. For variable-displacement pumps, confirm control linkages or electronic signal compatibility. Mismatches here lead to installation delays and potential hydraulic performance issues.

OEM vs High Quality Aftermarket: Choosing Between Authentic and High-Quality Replacements

Direct comparison: what changes between OEM and aftermarket?

OEM pumps are built to the original Caterpillar design and typically match factory tolerances, materials, and quality control. High Quality aftermarket pumps can match or exceed performance at a lower cost but vary by manufacturer. Key differences often appear in internal component materials, seal compounds, testing protocols, and warranty terms.

Cost, lead time, and total life-cycle value

Initial purchase price is only part of the story. Life-cycle cost considers uptime, fuel efficiency, maintenance intervals, and warranty support. An OEM pump with a higher purchase price may save money if it reduces downtime and maintenance. Conversely, a well-manufactured aftermarket pump can offer comparable performance and a shorter lead time.

Side-by-side spec comparison

| Feature | OEM Pump | High Quality Aftermarket Pump |

|---|---|---|

| Fit & Compatibility | Guaranteed direct fit to CAT 336D | Often direct fit; verify shaft/mount |

| Build Materials | Factory-specified alloys & seals | High-quality alloys; some use improved seal compounds |

| Testing & QA | Factory-tested to CAT standards | Varies; High Quality brands perform rigorous bench testing |

| Warranty & Support | Backed by CAT dealer network | Manufacturer warranty; dealer support varies |

| Price | Higher | Lower to comparable |

Practical Reliability Factors: Filtration, Fluid, and Maintenance

Hydraulic fluid cleanliness and filtration

Contamination is the top cause of hydraulic component failure. Follow ISO 4406 cleanliness targets appropriate for the 336D hydraulic system and install adequate filtration on return and pressure lines. For guidance on contamination control and fluid cleanliness, consult ISO 4406 (Hydraulic fluid contamination standard) and resources on hydraulic contamination management like Noria's hydraulic contamination resources.

Seal materials, temperature, and fluid compatibility

Choose pumps that use seals compatible with the hydraulic fluid you run (e.g., petroleum-based, biodegradable synthetic). Temperature extremes affect seal swelling and hardness—use materials rated for the service temperature range to avoid leaks. High Quality seal compounds can improve longevity in abrasive or hot conditions.

Predictive maintenance and diagnostics

Monitor pump health with simple checks: pressure and flow tests, suction condition (to avoid cavitation), operating temperature, and vibration analysis. Modern sensorization and telematics let you spot efficiency drops before catastrophic failure. A proactive maintenance plan reduces unscheduled downtime and lowers total operating cost.

Installation, Testing, and Field Commissioning Best Practices

Pre-installation checklist

- Verify pump model, mounting, and shaft orientation against machine serial and hydraulic schematics.

- Inspect hydraulic fluid cleanliness and top up or replace if needed to meet recommended ISO codes.

- Confirm hoses, couplings, and relief valve settings are correct for the pump’s flow and pressure.

Initial bench and field testing

On installation, perform a controlled run-in: gradually bring the pump up to operating pressure while monitoring for leaks, abnormal noise, and temperature rise. Check for correct flow at specified rpm, and validate relief valve setpoints. If available, use a calibrated flow meter and pressure gauge for objective verification.

Troubleshooting common startup issues

Typical early problems include air ingestion (suction leaks), cavitation, incorrect relief valve adjustment, and contamination. Solve suction-side problems by checking lines and fittings for tightness and unrestricted flow. If cavitation is suspected, inspect the suction line for restrictions, check inlet conditions, and verify the pump is sized properly for the system demands.

336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement (Product Highlight)

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Key features to evaluate when choosing this pump include displacement options, maximum pressure ratings, efficiency at rated rpm, and installed seal materials. If you need help confirming fit or control compatibility with your specific 336D serial number, consult your service manual or contact a certified technician.

References and further reading

- Hydraulic pump — Wikipedia

- ISO 4406 — Hydraulic fluid cleanliness standard

- Hydraulic fluid contamination resources — Noria

- Caterpillar (official)

Frequently Asked Questions (FAQ)

How do I know whether my CAT 336D needs a pump replacement or repair?

Signs that indicate replacement include persistent loss of flow or pressure, metal particles in hydraulic fluid, excessive noise, overheating, and frequent leak repairs. Conduct a flow and pressure test; if the pump shows poor volumetric efficiency or internal wear, replacement is often the more cost-effective option versus rebuild—especially if the pump has extensive internal damage.

Can I use an aftermarket pump in my 336D without problems?

Yes—provided the aftermarket pump meets the correct displacement, pressure rating, mounting and shaft specs, and uses compatible materials and seals. Choose High Quality aftermarket brands with strong QA, documented test results, and a warranty. When in doubt, compare specifications and request bench test data.

What filtration level should I maintain to protect a new hydraulic pump?

Target ISO cleanliness codes recommended for heavy equipment hydraulic systems commonly range from ISO 18/16/13 down to ISO 16/14/11 depending on component sensitivity. Consult your hydraulic component manufacturer for exact targets, and use high-quality filters on return and pressure circuits. For a detailed primer on contamination and filtration, see Noria’s resources.

How important is it to match the pump to the excavator's serial or model year?

Very important. Small changes in mounting flanges, control electronics, coupler types, or hydraulic circuit designs between production runs can require different pump variants. Always confirm compatibility by referencing the machine serial number and the parts catalog or a qualified dealer.

What maintenance steps extend the life of a hydraulic pump?

Maintain correct fluid levels and cleanliness, use the recommended hydraulic fluid, keep suction lines short and free of restrictions, maintain correct relief settings, and perform periodic vibration/temperature monitoring. Early intervention on detected anomalies prevents severe damage.

Contact / View Product

If you’re ready to replace or upgrade the hydraulic pump on your CAT 336D, view the product and full specifications or contact our sales and technical support team for fitment checks and quotes:

- View 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- Contact support: sales@example.com or call +1-800-555-1234

Our technical team can help you select OEM or High Quality aftermarket options, verify compatibility with your 336D’s serial number, and provide lead time and warranty details to keep your excavator productive.

Top 5 excavator hydraulic pump Company List and Products Compared

Excavator Engine Diagnostics: Tools and Techniques

How Hydraulic Pump Specs Affect 336D Excavator Performance

Common Causes of Excavator Hydraulic Pump Failure — Prevent, Diagnose, Replace

FAQ

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

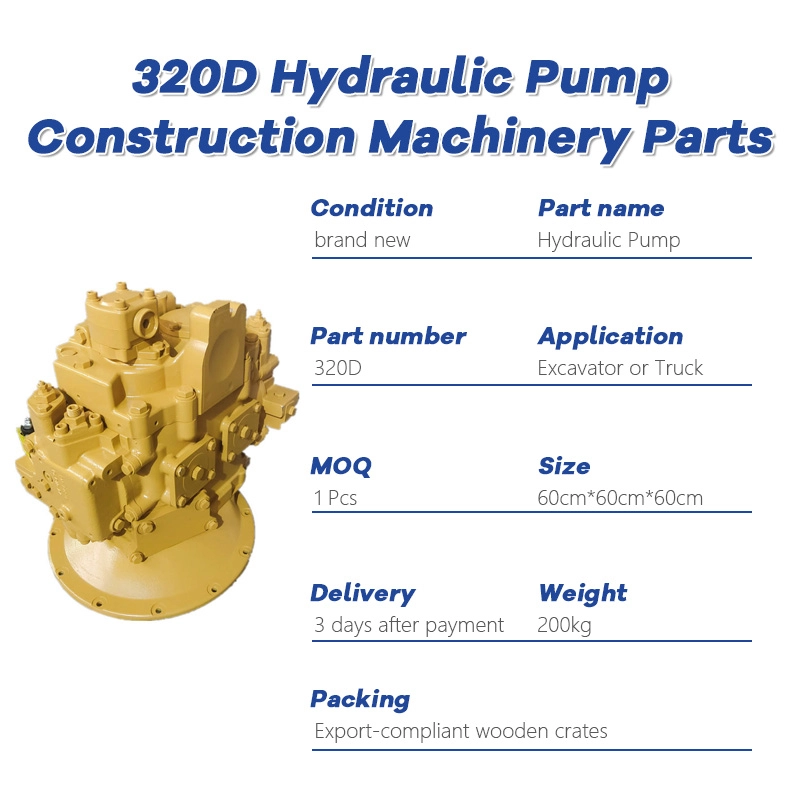

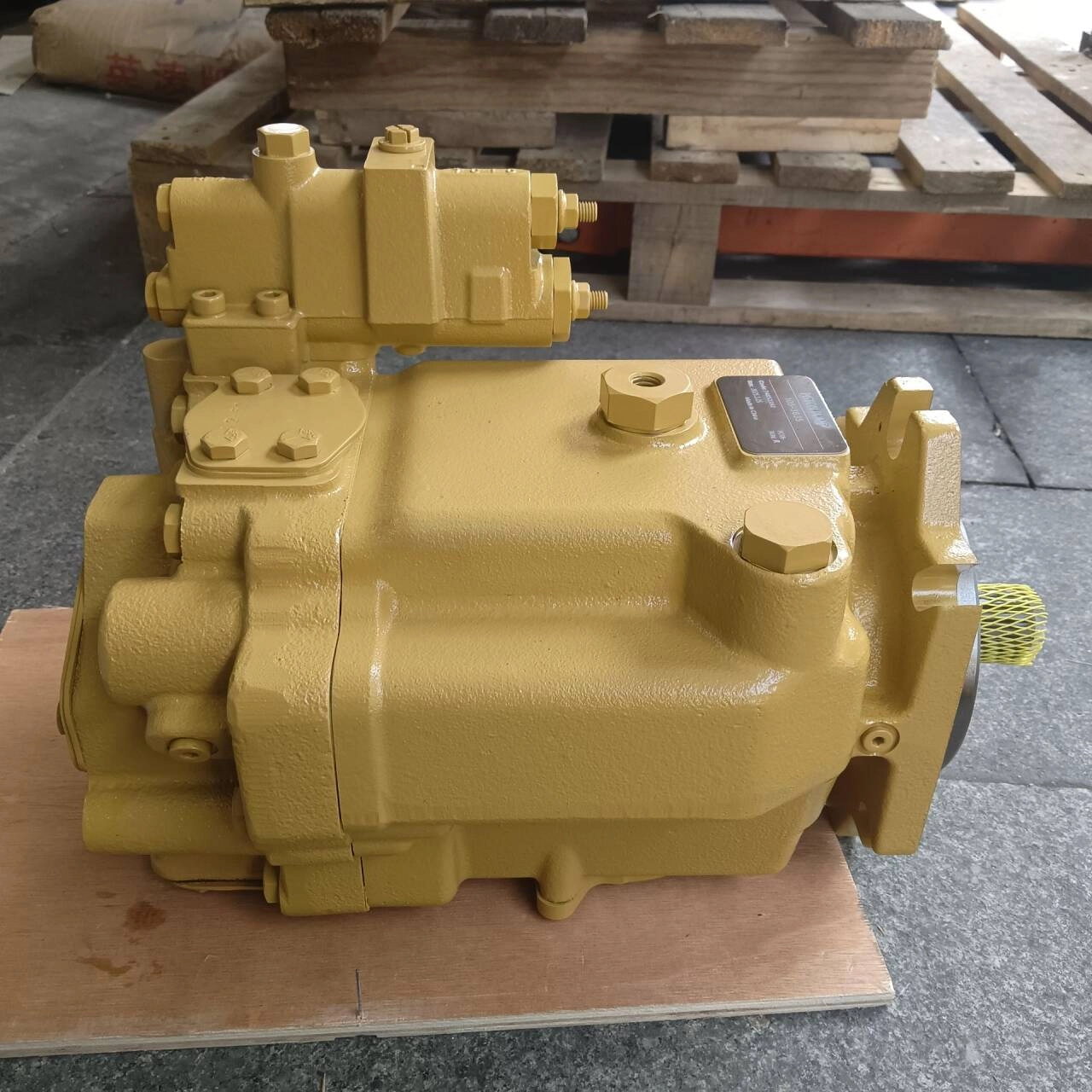

CAT 320D SBS120 Hydraulic Pump for Excavator | High Quality Replacement

This high-performance SBS120 hydraulic pump is specially designed for the CAT 320D excavator. Built with premium materials and precision manufacturing, it ensures reliable power delivery and long-lasting performance in tough construction environments. Ideal as an OEM replacement or aftermarket solution, this pump supports your hydraulic system with smooth, efficient operation.

-

Fits: Caterpillar 320D

-

Model: SBS120

-

Application: Excavator main hydraulic pump

-

Condition: New / Aftermarket available

-

Warranty: 6-12 months (optional)

-

Worldwide shipping available

-

CAT 980H Hydraulic Pump | Heavy-Duty Loader Replacement Part

The CAT 980H and 980G hydraulic pumps are engineered to provide optimal hydraulic power and durability for Caterpillar loaders. Built with premium materials and precision manufacturing, these pumps are ideal for OEM replacements and high-quality aftermarket upgrades. They ensure smooth hydraulic operation and reliable performance in demanding construction environments.

-

✔️ Direct fit for CAT 980H and 980G loaders

-

✔️ Available in OEM and aftermarket versions

-

✔️ High-pressure, heavy-duty hydraulic performance

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for durability and efficiency

-

✔️ Fast global shipping and excellent customer support

- 🛒 Order your CAT 980H & 980G Hydraulic Pump now!

📞 Contact us for bulk orders, technical support, or custom requests.

📦 Fast worldwide shipping | OEM & aftermarket options available -

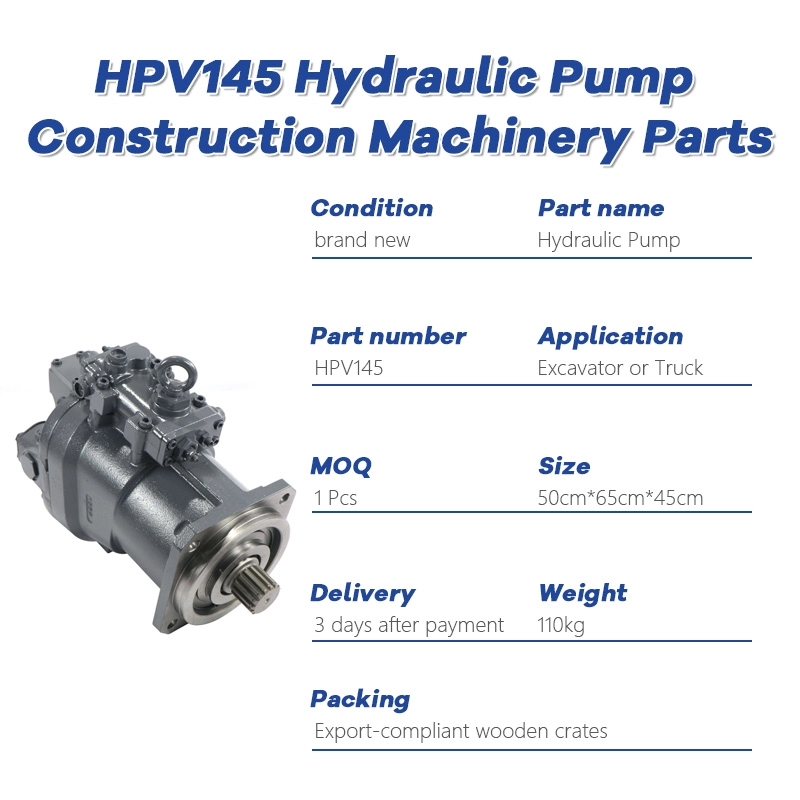

HPV145 Hydraulic Pump (Direct Injection) | Excavator Main Pump Replacement

The HPV145 single pump with direct injection technology is designed for excavators and heavy-duty machinery requiring precise hydraulic control and efficient power delivery. Combining advanced direct injection control with durable axial piston pump construction, this model ensures high performance, long service life, and reliable operation. Available in OEM and aftermarket versions, it is ideal for replacement or system upgrades.

-

✔️ Direct injection electronic control for precise hydraulic output

-

✔️ Suitable for excavators and various heavy machinery

-

✔️ High-pressure axial piston single pump design

-

✔️ OEM and aftermarket options for flexibility and cost-effectiveness

-

✔️ Robust materials and quality seals for long-term durability

-

✔️ Fast worldwide shipping and comprehensive technical support

- 🛒 Order Your HPV145 Direct Injection Single Pump Today – Precision, Durability & Performance

📞 Contact Us for pricing, availability, and technical support

🌍 Fast Global Shipping | OEM & Aftermarket | Secure Payment Options -

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -