jackhuang5919@gmail.com

How Hydraulic Pump Specs Affect 336D Excavator Performance

- Core hydraulic pump specs that determine 336D performance

- Flow rate and displacement: speed vs. force

- Maximum pressure and working pressure: hydraulic force and safety margins

- Volumetric and mechanical efficiency: real-world output and fuel use

- Pump types, control modes, and their impact on machine behavior

- Axial-piston vs. gear pumps: suitability for heavy-duty excavators

- Variable displacement and load-sensing controls

- Electro-proportional control compatibility

- How pump specs translate into field performance metrics

- Digging cycle time, bucket fill, and fuel consumption

- Push/pull forces and breakout torque

- Heat generation and hydraulic fluid life

- Selecting between OEM and high-quality aftermarket 336D hydraulic pumps

- Performance parity and warranty considerations

- Build materials, machining tolerances, and testing

- Cost of ownership: downtime, serviceability, and parts availability

- Installation, commissioning, and maintenance best practices

- Pre-install checks and hydraulic cleanliness

- Bleeding, setting relief pressures, and calibration

- Proactive monitoring and diagnostic indicators

- Data-driven comparison: OEM vs. High Quality aftermarket 336D pump (example values)

- Regulatory and standards references

- Practical recommendations for buying a 336D hydraulic pump

- Verify compatibility and control integration

- Demand test data and return policies

- Plan for downtime and spares strategy

- FAQ — Frequently asked questions

- Q: Can I replace a CAT 336D hydraulic pump with a lower-cost gear pump?

- Q: How do I confirm the new pump is compatible with my machine’s load-sensing system?

- Q: Will a higher-flow pump cause hydraulic system damage?

- Q: What maintenance steps extend pump life on a 336D?

- Q: Is an aftermarket pump as reliable as OEM for the 336D?

This article explains how hydraulic pump specifications affect the operational behavior and productivity of the CAT 336D excavator. It is written to help fleet managers, service technicians, and purchasing decision-makers quickly assess which pump characteristics matter most for digging force, swing torque, cycle times, fuel efficiency, and long-term reliability. The guidance combines engineering principles with practical field considerations to support effective choices between OEM and High Quality aftermarket 336D excavator hydraulic pumps.

Core hydraulic pump specs that determine 336D performance

Flow rate and displacement: speed vs. force

Flow rate (measured in liters per minute or gallons per minute) and pump displacement (cc/rev or in3/rev) are primary determinants of how quickly hydraulic actuators move. For the CAT 336D, higher pump flow increases boom/crowd/swing cylinder speeds and shortens cycle times, which translates into higher productivity on loading, trenching, and grading tasks. However, flow alone does not produce force — hydraulic pressure does.

Maximum pressure and working pressure: hydraulic force and safety margins

Maximum pressure rating and the recommended working pressure determine the achievable digging force and breakout torque. A pump rated for higher continuous working pressure lets the excavator generate greater cylinder thrust and swing torque without cavitation or excessive heat. Operators should ensure the pump's pressure rating matches the machine’s hydraulic relief and system design to avoid safety and reliability problems.

Volumetric and mechanical efficiency: real-world output and fuel use

Volumetric efficiency (how much fluid the pump actually delivers versus theoretical displacement) and mechanical efficiency (internal friction and losses) define how much engine power is converted into useful hydraulic work. Higher efficiencies reduce engine load and fuel consumption while maintaining performance under heavy duty cycles. When choosing a 336D hydraulic pump, prioritize pumps with documented efficiency curves and low internal leakage.

Pump types, control modes, and their impact on machine behavior

Axial-piston vs. gear pumps: suitability for heavy-duty excavators

Most modern excavators like the CAT 336D use variable-displacement axial-piston pumps rather than simple gear pumps. Axial-piston pumps offer controlled flow, higher pressure capacity, and better efficiency under varying loads. Gear pumps may be cheaper but typically lack the volumetric efficiency and pressure control needed for consistent heavy-duty operation on large machines.

Variable displacement and load-sensing controls

Variable displacement pumps with load-sensing (LS) control automatically adjust output to match demand, reducing wasted flow and lowering fuel consumption. On a 336D, LS pumps maintain hydraulic responsiveness during simultaneous multi-function operations (e.g., swing while crowding), improving controllability and operator comfort. Make sure replacement pumps support the machine’s existing LS or electro-hydraulic control scheme.

Electro-proportional control compatibility

If the machine uses electro-proportional valves and electronic control systems, the hydraulic pump must integrate seamlessly with those controls. Mismatched pump control characteristics can increase response time, produce jerky motion, or trigger alarms. Confirm electronic compatibility and sensor ports when selecting a replacement pump for the 336D.

How pump specs translate into field performance metrics

Digging cycle time, bucket fill, and fuel consumption

Higher usable flow usually shortens digging cycles and increases cubic meters moved per hour, but only when combined with adequate pressure and efficiency. A pump with poor volumetric efficiency or internal leakage can increase engine RPM and fuel use while delivering reduced flow under load. Selecting a high-performance CAT 336D hydraulic pump—whether OEM or a high-quality aftermarket option—protects cycle time and fuel efficiency.

Push/pull forces and breakout torque

Breakout force depends on system pressure and actuator area. A pump that can sustain required working pressure without excessive drop ensures consistent breakout torque. If a replacement pump has lower pressure capacity or thermal limitations, the machine will exhibit reduced digging power, especially in deep or compacted materials.

Heat generation and hydraulic fluid life

Pumps with lower efficiency generate more heat, stressing hydraulic fluid and seals. Elevated operating temperatures accelerate oxidation and contamination, shortening component life. Choosing a pump with high mechanical and volumetric efficiency helps keep operating temperatures within recommended ranges and extends time between fluid changes and service intervals.

Selecting between OEM and high-quality aftermarket 336D hydraulic pumps

Performance parity and warranty considerations

OEM pumps are engineered to match factory performance, materials, and control characteristics. Many High Quality aftermarket manufacturers now achieve near-OEM performance with cost savings. When evaluating options for a 336D, compare published specs (flow, max/working pressure, displacement), test data for volumetric/mechanical efficiency, and warranty terms. Prefer suppliers who provide performance curves and test certificates.

Build materials, machining tolerances, and testing

Look for pumps with hardened surfaces, precision-bearing assemblies, and proper sealing technology. Rigorous factory testing—pressure, endurance, leak, and noise tests—indicates quality control. The provided product, CAT 336D hydraulic pump, notes high-pressure performance and rigorous testing; confirm similar claims with independent test reports or ISO-aligned procedures.

Cost of ownership: downtime, serviceability, and parts availability

Lower upfront cost from a discount aftermarket pump can be offset by higher downtime, shortened seal life, or poorer efficiency. Factor in time-to-repair, local parts availability, and global shipping support. The listed product emphasizes global shipping and responsive support—key considerations for contractors who cannot afford extended downtime on site.

Installation, commissioning, and maintenance best practices

Pre-install checks and hydraulic cleanliness

Before installing a replacement pump on a CAT 336D, confirm system cleanliness; particulate contamination is a leading cause of pump failure. Follow ISO 4406 cleanliness targets recommended for hydraulic systems (see ISO cleanliness standards) and flush lines if necessary. Use manufacturer-recommended filtration and replace suction strainers and return-line filters during pump changeover.

Bleeding, setting relief pressures, and calibration

After installation, bleed air and confirm relief and counterbalance settings match the machine’s specification. Improper relief pressure settings can overload the pump or the machine’s components. Verify that electronic load-sensing signals and pressure transducers are calibrated when applicable.

Proactive monitoring and diagnostic indicators

Use temperature, pressure, and return-line particle monitors to spot developing issues early. A rising return-line temperature or increased particulate counts indicate wear or contamination. Implement scheduled inspections: check for seepage, unusual noise, and vibration—common early signs of hydraulic pump degradation.

Data-driven comparison: OEM vs. High Quality aftermarket 336D pump (example values)

| Spec | OEM CAT 336D Pump | High Quality Aftermarket Pump |

|---|---|---|

| Nominal Flow | 400 L/min (example) | 395–410 L/min (tested range) |

| Max Working Pressure | 350 bar | Up to 350 bar (specified) |

| Volumetric Efficiency @ rated load | ~96% | ~94–96% (depends on design) |

| Warranty | Manufacturer warranty | 1–3 years (vendor-dependent) |

| Typical Price | Higher upfront | Lower to comparable |

Note: the values above are illustrative—always verify exact specifications from product datasheets and performance certificates before purchase.

Regulatory and standards references

When assessing pump specifications and installation procedures, consult internationally recognized standards for hydraulic systems and components. Relevant references include the hydraulic pump overview on Wikipedia: Hydraulic pump for fundamental principles, and the ISO 4413 standard for hydraulic fluid power safety and general rules. Industry publications and technical resources such as Hydraulics & Pneumatics provide applied guidance on pump selection and system troubleshooting.

For machine-specific guidance and parts compatibility, refer to official Caterpillar documentation and parts catalogues available through Cat.com or authorized dealers.

Practical recommendations for buying a 336D hydraulic pump

Verify compatibility and control integration

Confirm that the replacement pump matches mounting, shaft, porting, and control interfaces (mechanical/electronic) of the CAT 336D. Mismatches can necessitate adapter plates, custom hoses, or reprogramming—each adding cost and risk.

Demand test data and return policies

Reputable vendors will provide performance curves, efficiency curves, pressure vs. flow charts, and test certificates. A clear return policy and warranty that covers working pressure and premature failures are strong indicators of product confidence.

Plan for downtime and spares strategy

Large excavators are critical assets—minimize downtime by keeping a spare pump on hand for multi-machine fleets, or aligning replacement timing with scheduled maintenance windows. For remote sites, verify global shipping and vendor support to reduce lead times; the featured CAT 336D hydraulic pump highlights global shipping and responsive support as key benefits.

FAQ — Frequently asked questions

Q: Can I replace a CAT 336D hydraulic pump with a lower-cost gear pump?

A: For the CAT 336D, a gear pump is generally not recommended because it will not provide the control, pressure capacity, or efficiency of a variable-displacement axial-piston pump. This will reduce performance, increase fuel use, and likely shorten component life.

Q: How do I confirm the new pump is compatible with my machine’s load-sensing system?

A: Check the pump’s control ports, signal response characteristics, and manufacturer documentation. If possible, obtain compatibility confirmation in writing from the vendor and verify during commissioning with the machine’s diagnostic tools.

Q: Will a higher-flow pump cause hydraulic system damage?

A: Not if the system is designed for it. Excessive flow without proper valve sizing or heat rejection can create higher internal velocities and turbulence, increasing heat and wear. Always ensure the control valves, hoses, and coolers are sized for the selected pump flow and that relief settings are correctly adjusted.

Q: What maintenance steps extend pump life on a 336D?

A: Maintain hydraulic cleanliness (ISO 4406 targets), use the correct hydraulic fluid and viscosity recommended by the OEM, monitor return-line temperature and particle counts, and adhere to scheduled filter and fluid changes. Address leaks and vibration issues promptly.

Q: Is an aftermarket pump as reliable as OEM for the 336D?

A: High-quality aftermarket pumps from reputable manufacturers can match OEM reliability and performance. Verify through test data, warranty offerings, and field references. Beware of low-cost unknown suppliers without verifiable test records.

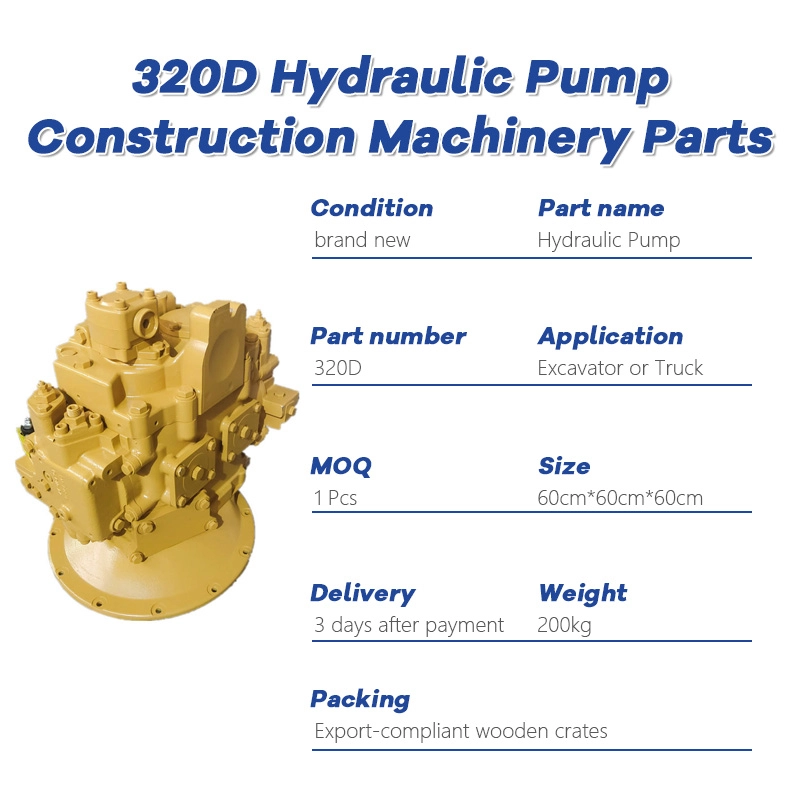

If you need a direct-fit replacement or upgrade for your machine, consider the 336D product described here:

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Contact our technical sales team to discuss pump specifications, request performance curves, or schedule installation support: sales@example.com. View the product details and order the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement on our product page: /products/336d-excavator-hydraulic-pump.

Authoritative references: Wikipedia (hydraulic pump) https://en.wikipedia.org/wiki/Hydraulic_pump; ISO 4413 (Hydraulic fluid power — general rules) https://www.iso.org/standard/57725.; Hydraulics & Pneumatics technical resources https://www.hydraulicspneumatics.com/; Caterpillar home page https://www.cat.com.

Hydraulic Pump Retrofit Options for Older Excavators 2026

Hydraulic Pump Flow Control Valve Optimization 2026

Lifecycle cost benefits of original engine assemblies

Choosing the Right Hydraulic Pump for Doosan DX65

FAQ

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

CAT 320D SBS120 Hydraulic Pump for Excavator | High Quality Replacement

This high-performance SBS120 hydraulic pump is specially designed for the CAT 320D excavator. Built with premium materials and precision manufacturing, it ensures reliable power delivery and long-lasting performance in tough construction environments. Ideal as an OEM replacement or aftermarket solution, this pump supports your hydraulic system with smooth, efficient operation.

-

Fits: Caterpillar 320D

-

Model: SBS120

-

Application: Excavator main hydraulic pump

-

Condition: New / Aftermarket available

-

Warranty: 6-12 months (optional)

-

Worldwide shipping available

-

CAT 980H Hydraulic Pump | Heavy-Duty Loader Replacement Part

The CAT 980H and 980G hydraulic pumps are engineered to provide optimal hydraulic power and durability for Caterpillar loaders. Built with premium materials and precision manufacturing, these pumps are ideal for OEM replacements and high-quality aftermarket upgrades. They ensure smooth hydraulic operation and reliable performance in demanding construction environments.

-

✔️ Direct fit for CAT 980H and 980G loaders

-

✔️ Available in OEM and aftermarket versions

-

✔️ High-pressure, heavy-duty hydraulic performance

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for durability and efficiency

-

✔️ Fast global shipping and excellent customer support

- 🛒 Order your CAT 980H & 980G Hydraulic Pump now!

📞 Contact us for bulk orders, technical support, or custom requests.

📦 Fast worldwide shipping | OEM & aftermarket options available -

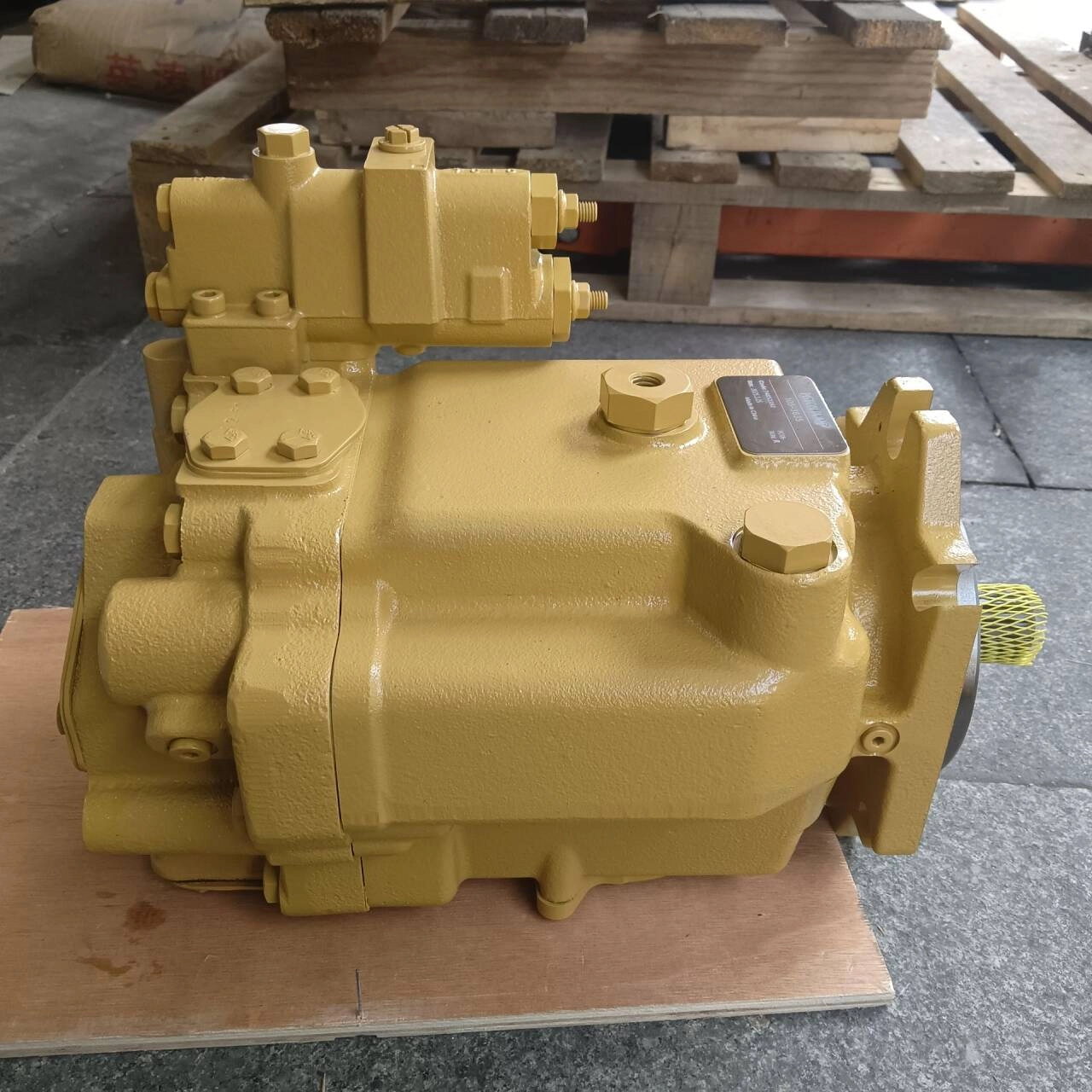

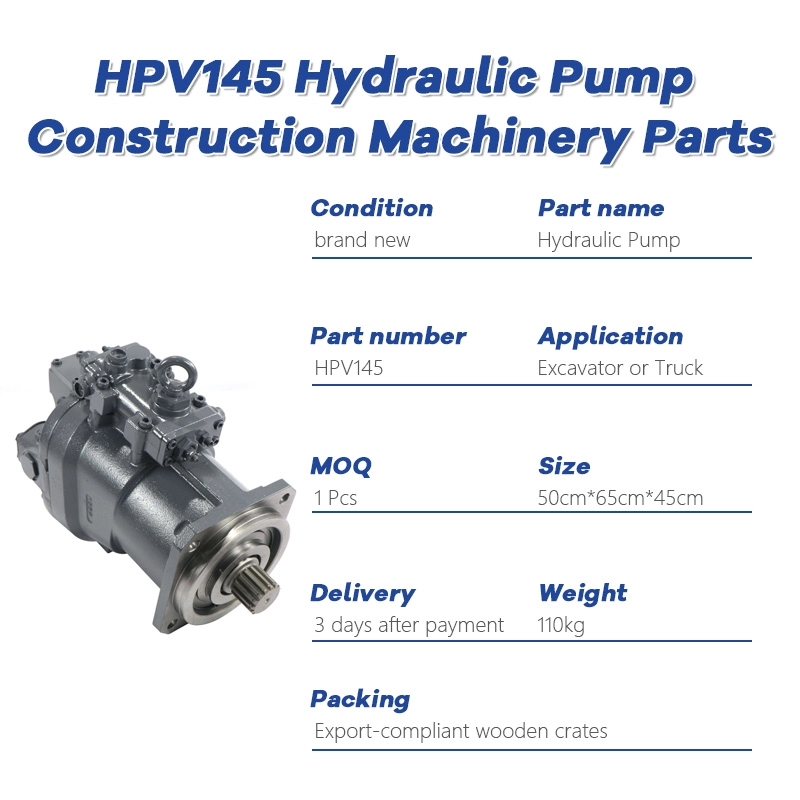

HPV145 Hydraulic Pump (Direct Injection) | Excavator Main Pump Replacement

The HPV145 single pump with direct injection technology is designed for excavators and heavy-duty machinery requiring precise hydraulic control and efficient power delivery. Combining advanced direct injection control with durable axial piston pump construction, this model ensures high performance, long service life, and reliable operation. Available in OEM and aftermarket versions, it is ideal for replacement or system upgrades.

-

✔️ Direct injection electronic control for precise hydraulic output

-

✔️ Suitable for excavators and various heavy machinery

-

✔️ High-pressure axial piston single pump design

-

✔️ OEM and aftermarket options for flexibility and cost-effectiveness

-

✔️ Robust materials and quality seals for long-term durability

-

✔️ Fast worldwide shipping and comprehensive technical support

- 🛒 Order Your HPV145 Direct Injection Single Pump Today – Precision, Durability & Performance

📞 Contact Us for pricing, availability, and technical support

🌍 Fast Global Shipping | OEM & Aftermarket | Secure Payment Options -

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -