jackhuang5919@gmail.com

Installation Checklist for Doosan DX65 Main Hydraulic Pump

- Pre-Installation Preparation for DX65 Hydraulic Pump

- Tools, Safety Equipment and Workspace Setup

- Verify Pump Compatibility and Part Verification

- Inspect Existing Hydraulic System and Pre-Clean Steps

- Step-by-Step Installation Checklist

- Removal of the Old Pump

- Mounting the New Pump and Torque Specifications

- Hydraulic Connections, Seals and Bleeding

- Testing, Calibration and Troubleshooting

- Pressure and Performance Testing

- Common Installation Issues and Solutions

- Post-Installation Calibration and Break-In

- Maintenance Practices to Extend Pump Life

- Routine Inspections and Fluid Management

- Preventive Measures and Scheduled Maintenance

- When to Replace vs Repair

- Product & Brand Advantages — Why Choose Our DX65 Hydraulic Pump

- OEM and Aftermarket Quality

- Testing, Packaging and Global Support

- Warranty, Documentation and Expert Support

- Frequently Asked Questions (FAQ)

- Q: How do I confirm the replacement pump fits my Doosan DX65?

- Q: What hydraulic fluid should I use after installation?

- Q: How long is the break-in period and what steps should I follow?

- Q: Can I use an aftermarket pump instead of OEM?

- Q: Why did my new pump fail quickly after installation?

The Doosan DX65 Excavator Hydraulic Pump | High-Performance Main Pump is engineered for Doosan DX65 mini excavators, delivering consistent hydraulic power for smooth machine operation. Whether replacing a worn hydraulic pump or upgrading to a higher-performance axial piston pump, our OEM and aftermarket DX65 pumps are built with high-quality materials and precision engineering to reduce downtime and extend service life. This checklist offers a practical, step-by-step installation and verification workflow so your machine returns to full capability safely and reliably.

With your pump installed and operational, revisit the choosing the right hydraulic pump for Doosan DX65 process for any future upgrades or maintenance, ensuring you’re always ready to make the best decision for your fleet.

Pre-Installation Preparation for DX65 Hydraulic Pump

Tools, Safety Equipment and Workspace Setup

Prepare a clean, level workspace and collect the following: torque wrench (range suited to pump mounting bolts), hydraulic line wrenches, new O-rings and seals, pump mounting gasket (if required), calibrated pressure gauge, hydraulic fluid recommended by Doosan, clean fluid containers, lifting sling or engine hoist (if needed), and PPE (gloves, eye protection). A contamination-controlled area reduces the risk of debris entering the hydraulic system — contamination is a leading cause of hydraulic pump failure according to industry guidance (see general pump contamination risks: Wikipedia - Hydraulic pump).

Verify Pump Compatibility and Part Verification

Confirm the replacement pump matches the Doosan DX65 specifications. Check part numbers, shaft orientation, mounting flange, displacement, and port locations. Our DX65 hydraulic pump is 100% fit for Doosan DX65 excavators and available in axial piston configurations for compact high-power installation. If you source OEM vs aftermarket, compare test records for pressure and fluid consistency; both OEM and high-quality aftermarket options should include testing documentation.

Inspect Existing Hydraulic System and Pre-Clean Steps

Before removal, inspect hoses, fittings, and filters. Note any signs of contamination, metal particles, or degraded seals. Replace hydraulic filters and drain the system into clean, sealed containers for inspection. A quick particle count or visual check can indicate prior pump wear. If severe contamination is present, perform a system flush; otherwise, contaminants can destroy a new hydraulic pump within hours.

Step-by-Step Installation Checklist

Removal of the Old Pump

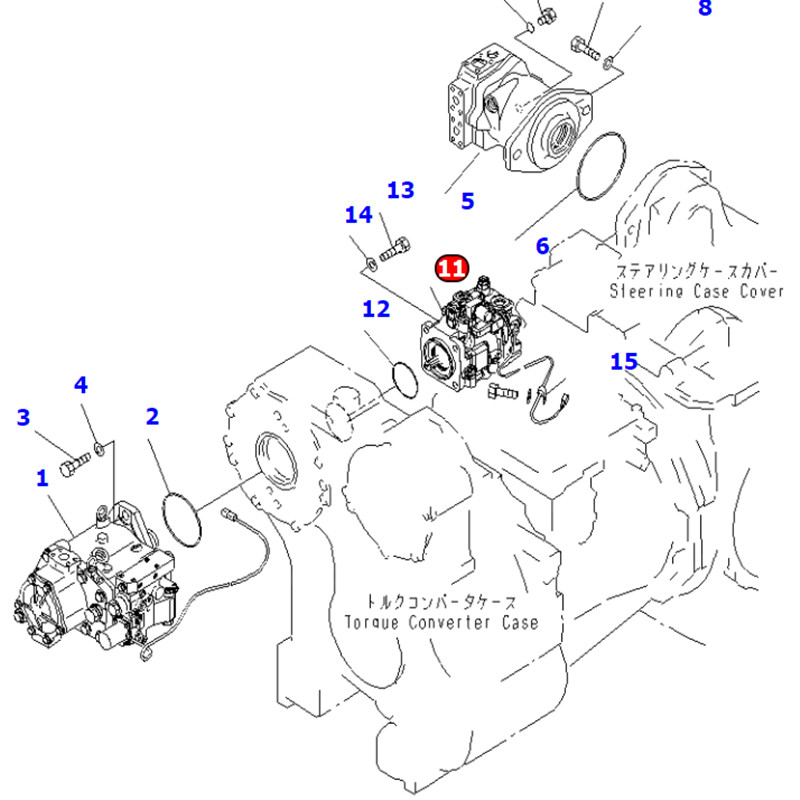

1) Depressurize the hydraulic system per Doosan safety guidelines. 2) Tag and photo all hydraulic lines and electrical connectors to ensure correct reconnection. 3) Remove supply and return lines using correct wrenches; cap lines to prevent contamination. 4) Loosen mounting bolts in a star pattern and support the pump. Carefully extract the old pump, noting mounting gasket condition and alignment dowel pins.

Mounting the New Pump and Torque Specifications

Inspect the mounting flange for burrs or damage. Install a new gasket or seal if required. Align pump keyed shaft and dowel pins precisely to avoid misalignment loads. Tighten mounting bolts in a star pattern to the torque values specified below. Under- or over-torquing can lead to misalignment, leakage, or stress cracks.

| Item | Recommended Value | Notes |

|---|---|---|

| Mounting bolt torque | 25–45 N·m (check OEM manual) | Typical range; confirm with pump plate-specific spec |

| Operating pressure (max) | Up to 250 bar (model dependent) | Test with calibrated gauge prior to load |

| Hydraulic fluid | Doosan-recommended hydraulic oil (ISO VG 46 commonly used) | Use manufacturer fluid to ensure compatibility |

Note: The torque and pressure values above are general guidelines. Consult the Doosan service manual for the DX65 for exact mounting torque and hydraulic pressure limits available at Doosan's official site (Doosan).

Hydraulic Connections, Seals and Bleeding

Reconnect supply and return lines using new O-rings or bonded seals where applicable. Tighten fittings to manufacturer spec, then slowly fill the system with clean hydraulic fluid. Bleed air from the circuit following this sequence: prime the pump by turning the engine at low idle (or using electric priming if provided), cycle the control valves to purge trapped air, and re-check fluid level. Air in the hydraulic circuit reduces flow and causes noise, cavitation and premature pump wear.

Testing, Calibration and Troubleshooting

Pressure and Performance Testing

With the pump installed and the system bled, conduct pressure and flow tests. Attach a calibrated gauge to the test port, and verify that relief and work pressures reach expected values without excessive fluctuation. Compare results to baseline specifications. The DX65 pump is tested for pressure and performance before shipping, but field verification is essential for system-specific factors such as hose length and valve settings.

Common Installation Issues and Solutions

1) Low flow or pressure: Check for air in the system, incorrect pump displacement selection, clogged suction filters, or incorrect shaft rotation. 2) Noise or cavitation: Inspect fluid level, suction line leaks, or restrictions. 3) External leakage: Ensure seals and fittings are properly seated and torqued; replace damaged O-rings. 4) Rapid wear: Check contamination levels and filtration strategy.

Post-Installation Calibration and Break-In

Run the machine under light load for the initial break-in period (typically one to two hours) while monitoring temperature, pressure, and fluid condition. Check for leaks again and retorque critical fasteners after initial thermal cycles. Record performance data for warranty and future maintenance reference. Proper break-in improves surface mating in axial piston pumps and stabilizes performance.

Maintenance Practices to Extend Pump Life

Routine Inspections and Fluid Management

Regularly inspect hydraulic fluid condition, filter condition, and connection points. Replace filters per Doosan intervals or more frequently in dusty applications. Use particle counters or laboratory fluid analysis for fleets — early detection of wear metals helps avoid catastrophic failures.

Preventive Measures and Scheduled Maintenance

Maintain a maintenance log, and schedule periodic system flushes if contamination levels increase. Ensure ventilation and cooling systems are functioning to prevent fluid overheating, which accelerates seal degradation. The use of correct fluid viscosity and additives recommended by Doosan ensures proper lubrication of pump components.

When to Replace vs Repair

If hydraulic pump performance drops below acceptable levels (recurrent cavitation, metal particles in filters, excessive internal leakage), replacement of the main hydraulic pump is usually the most cost-effective solution compared to repeated repairs. Our DX65 pumps undergo precision sealing with robust alloy components to reduce lifecycle costs and downtime.

Product & Brand Advantages — Why Choose Our DX65 Hydraulic Pump

OEM and Aftermarket Quality

We supply both OEM and high-quality aftermarket Doosan DX65 hydraulic pumps. Each pump is manufactured with precision engineering and high-quality materials. The DX65 pump is an axial piston pump — compact and powerful — designed for reliable excavator service. Independent testing for pressure, performance, and fluid consistency is available to customers prior to shipping.

Testing, Packaging and Global Support

All pumps are tested for pressure and flow before dispatch. We ship globally with secure wooden packaging to prevent transport damage and offer global logistics support. For large orders we provide bulk pricing, compatibility checks, and inventory updates. Order your Doosan DX65 Hydraulic Pump today — performance you can trust.

Warranty, Documentation and Expert Support

We provide installation support documentation and technical help for installation, testing, and troubleshooting. Warranty coverage and tested returns procedures are available — contact our technical team for compatibility confirmation and installation guidance.

Frequently Asked Questions (FAQ)

Q: How do I confirm the replacement pump fits my Doosan DX65?

A: Verify the OEM part number, shaft orientation, mounting flange pattern, and pump displacement. Photos and measurements can be submitted to our compatibility team for confirmation. Our DX65 hydraulic pump models are 100% fit for Doosan DX65 excavators.

Q: What hydraulic fluid should I use after installation?

A: Use the Doosan-recommended hydraulic oil. Many DX65 applications use ISO VG 46 hydraulic fluid, but always confirm with the excavator service manual or the fluid label. Using the correct fluid preserves valve function and pump longevity. See Doosan's general maintenance guidance at Doosan.

Q: How long is the break-in period and what steps should I follow?

A: Run the machine at light load for 1–2 hours, cycling all controls to seat moving parts and purge residual air. Monitor temperature, pressure and fluid level continuously during this period.

Q: Can I use an aftermarket pump instead of OEM?

A: High-quality aftermarket pumps can meet or approach OEM performance while offering cost savings. Choose a supplier who provides testing documentation for pressure and flow, and aligns components with Doosan design dimensions. We offer both OEM and trusted aftermarket DX65 pumps tested for performance and consistency.

Q: Why did my new pump fail quickly after installation?

A: Rapid failure is often caused by contamination, trapped air, insufficient filtration, incorrect fluid, or misalignment during installation. Follow the checklist above: ensure cleanliness, correct torques, proper bleeding, and filtration to prevent early failure.

Contact & Product Call to Action

Order your Doosan DX65 Hydraulic Pump today — performance you can trust. For stock availability, bulk pricing, compatibility checks, or installation support, contact our sales team or visit the product page. Fast global shipping, OEM & aftermarket options, and secure payment solutions are available.

References: General hydraulic pump overview: Wikipedia - Hydraulic pump. Manufacturer information and service recommendations: Doosan.

Upgrading Your Excavator Engine for More Power

Selecting the Right Flow and Pressure for DX65 Pump

Hydraulic Pump Replacement Checklist for Excavator Parts 2026

Emissions and Regulations: ZAX870-5G 6WG1 Compliance Tips

FAQ

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -