jackhuang5919@gmail.com

Buyer's Guide: Choosing a Hydraulic Hydraulic Pump for Excavators

- Buyer's Guide: Choosing a Hydraulic Hydraulic Pump for Excavators

- Why the Right Hydraulic Hydraulic Pump Matters for Excavator Performance

- Overview: 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- Understanding Pump Types and How They Impact Excavator Duty

- Compatibility Checklist: Ensuring a Correct Fit for CAT 336D

- OEM vs Aftermarket: Which Hydraulic Pump Should You Choose?

- Performance Specs You Must Verify

- Installation Tips to Avoid Early Failures

- Maintenance Best Practices for Long Pump Life

- Troubleshooting Common Pump Problems

- Cost of Ownership: What to Budget For

- How to Verify Seller Credibility and Product Quality

- Brand Advantages: Why Choose the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- FAQ — Frequently Asked Questions

- Contact & Where to Buy — Next Steps

- Authoritative References

Buyer's Guide: Choosing a Hydraulic Hydraulic Pump for Excavators

Why the Right Hydraulic Hydraulic Pump Matters for Excavator Performance

The hydraulic hydraulic pump is the heart of an excavator's powertrain. It converts engine mechanical power into hydraulic energy that moves the boom, arm, bucket, and swing systems. Choosing the correct pump affects machine productivity, fuel efficiency, component life, and downtime. For operators and fleet managers running heavy machines like the CAT 336D, selecting a durable, high-pressure pump that fits correctly is essential to maintain performance in harsh construction environments. After reading the buyer’s guide: choosing a hydraulic hydraulic pump for excavators, procurement teams often move to model-specific requirements, starting with the spec checklist for 336D excavator hydraulic pump replacements.

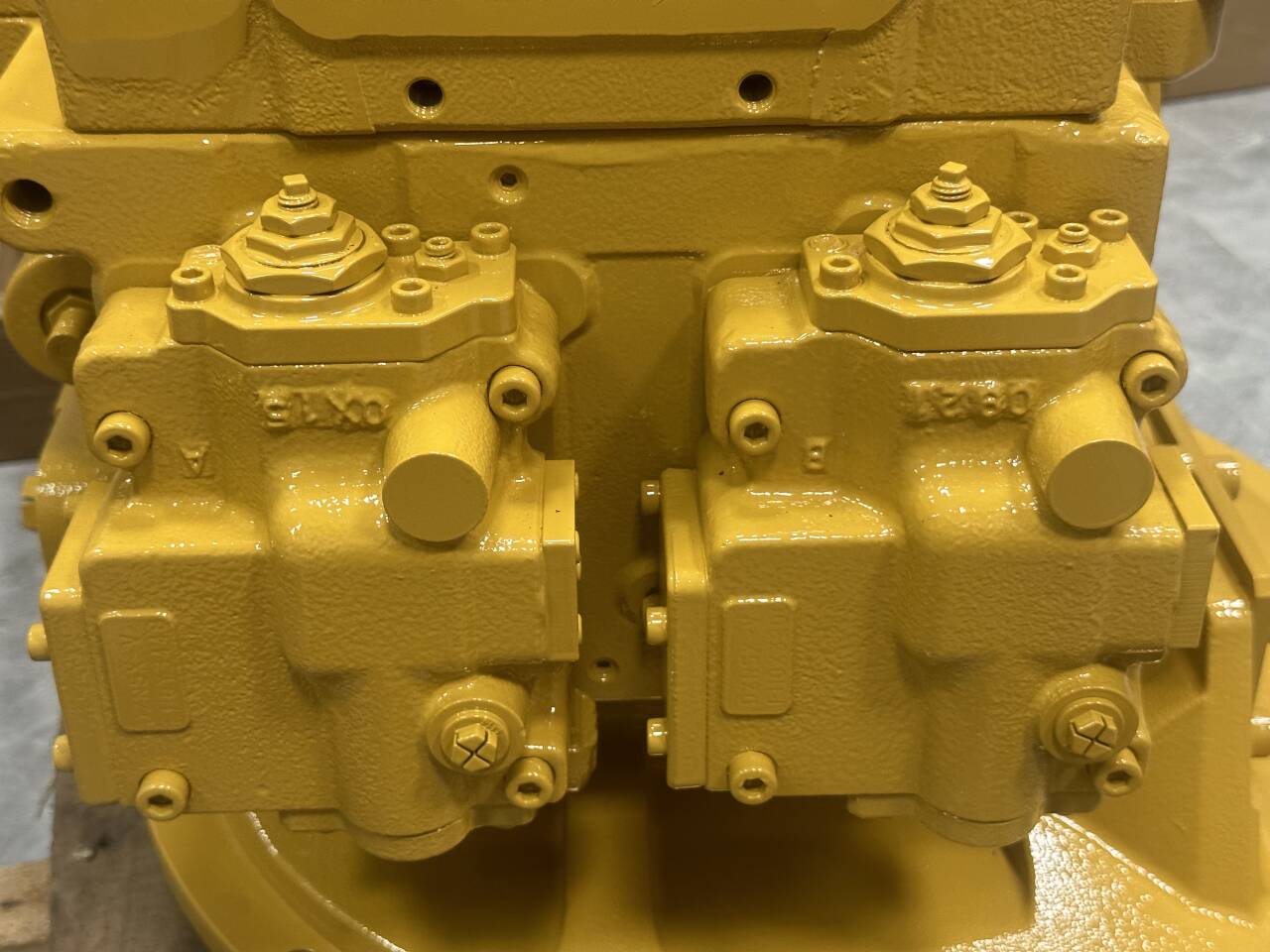

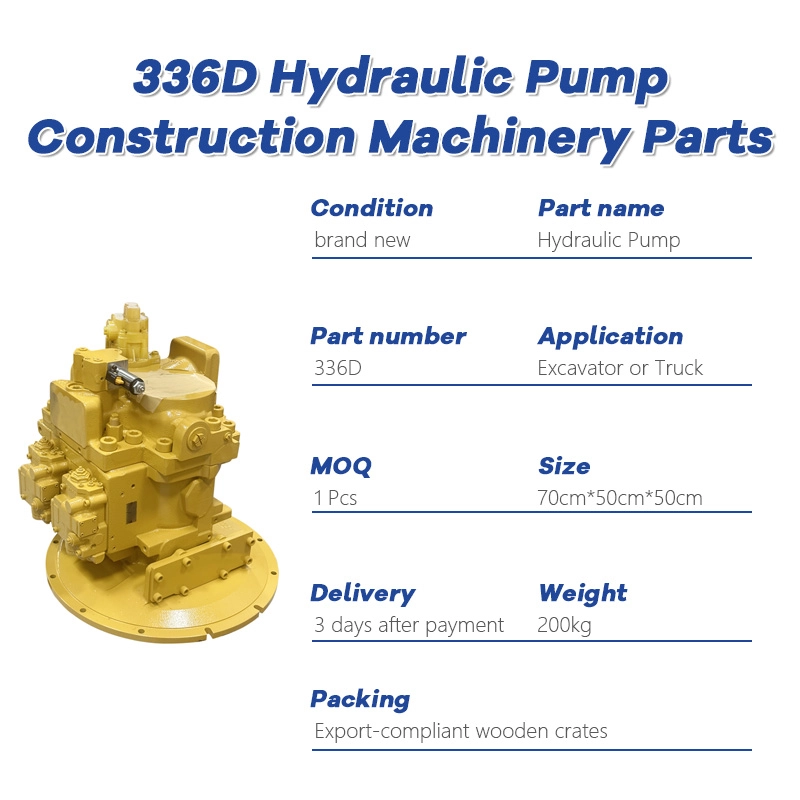

Overview: 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Understanding Pump Types and How They Impact Excavator Duty

Hydraulic pumps for excavators typically come in three categories: gear, vane, and piston pumps. For heavy excavators such as the CAT 336D, axial piston pumps are the common choice because they deliver high pressure, better efficiency, and variable displacement capabilities to match different loads. When choosing a hydraulic hydraulic pump, focus on these attributes:

- Displacement and flow rate: Match pump displacement to the hydraulic system's required flow (L/min or gpm).

- Maximum pressure: Verify the pump's rated pressure meets or exceeds the system's peak pressure.

- Variable vs fixed displacement: Variable pumps offer efficiency and control advantages for modern excavator controls.

- Mounting and shaft interface: Ensure the pump's flange, bolt pattern, and shaft type are compatible with the CAT 336D drive train.

Compatibility Checklist: Ensuring a Correct Fit for CAT 336D

Before purchasing a hydraulic hydraulic pump, confirm these points to avoid fitment or performance issues:

- Model and serial number verification—match to excavator SAM (Service and Maintenance) records.

- Physical dimensions and weight—to ensure proper installation and clearance.

- Hydraulic ports and thread types—metric vs imperial and orientation matters.

- Drive shaft splines or keyway specification—incorrect coupling causes failure.

- Control signal compatibility—electro-hydraulic systems may need matching sensors or swashplate actuators.

OEM vs Aftermarket: Which Hydraulic Pump Should You Choose?

There is often a trade-off between cost and risk when deciding on OEM (original equipment manufacturer) versus High Quality aftermarket pumps. Below is a direct comparison to help weigh the options.

| Feature | OEM CAT Pump | High Quality Aftermarket Pump |

|---|---|---|

| Fit & Compatibility | Guaranteed direct fit for CAT 336D | Often direct fit; verify part number and specs |

| Performance & Tolerances | Manufacturer-tested to original specs | High-quality options meet or exceed specs; variability exists |

| Warranty & Support | Comprehensive factory warranty and dealer support | Good aftermarket warranties available; check provider reputation |

| Price | Higher initial cost | Typically lower cost; better value with High Quality brands |

| Lead Time | Often available through dealer networks | May be faster or slower depending on supplier stock |

| Quality Consistency | High and consistent | High for High Quality suppliers; lower for unknown brands |

Recommendation: For fleets where uptime and predictable lifecycle costs matter, OEM parts are a safer bet. For cost-sensitive repairs, choose a reputable aftermarket supplier that provides clear specifications, documentation, and warranty.

Performance Specs You Must Verify

When evaluating a pump listing or datasheet, confirm these essential specifications:

- Rated pressure (bar/psi).

- Maximum flow (L/min or gpm) at rated speed.

- Displacement per revolution (cc/rev).

- Operating speed range (rpm).

- Mounting pattern and flange type.

- Shaft diameter, spline count, and keyway details.

- Recommended hydraulic fluid type and viscosity range.

Installation Tips to Avoid Early Failures

Proper installation is critical to ensure the longevity of your hydraulic hydraulic pump and the entire excavator hydraulic system. Follow these practical steps:

- Always clean the area and use clean tools—contaminants cause rapid wear.

- Replace hydraulic filters before startup to prevent debris recirculation.

- Bleed air from the system per the manufacturer procedure to prevent cavitation.

- Use the recommended hydraulic oil and fill to specified levels; wrong fluid can reduce lubrication and cause overheating.

- Torque bolts to specified values to avoid misalignment or leaks.

- Run the system at low loads initially and check for leaks, unusual noise, or vibration.

Maintenance Best Practices for Long Pump Life

Routine maintenance increases pump longevity and lowers lifetime costs. Implement these practices in your maintenance schedule:

- Regularly inspect for leaks, bearing play, and unusual noise.

- Change hydraulic oil and filters on the schedule recommended by Caterpillar or your pump supplier.

- Monitor operating temperatures—overheating shortens seal and component life.

- Use particle counters or oil analysis to detect early wear signs.

- Keep hydraulic hoses and fittings in good condition to prevent pressure spikes.

Troubleshooting Common Pump Problems

Recognizing symptoms early saves expensive repairs. Common issues and likely causes:

- Low pressure or slow movements: Worn pump components or internal leakage—check displacement and wear limits.

- Excessive noise: Cavitation from air in fluid, clogged suction, or fluid viscosity issues.

- Overheating: Excessive load, low fluid level, or wrong oil viscosity.

- Leakage: External seals failing—inspect fittings and mounting gaskets.

Cost of Ownership: What to Budget For

When budgeting for a replacement hydraulic hydraulic pump for a CAT 336D, consider these cost elements:

- Part cost (OEM vs aftermarket).

- Labor for removal, installation, and testing.

- Associated parts: seals, filters, hoses, fluids.

- Potential downtime and loss of productivity.

- Extended warranty or service plans to reduce future risk.

How to Verify Seller Credibility and Product Quality

When buying a replacement pump, especially aftermarket units, verify the seller and product with these checks:

- Supplier certifications (ISO, aftermarket manufacturer certifications).

- Customer reviews and case studies with heavy equipment users.

- Warranty terms and clear RMA policies.

- Availability of technical support and replacement parts.

- Documentation—detailed datasheets, installation guides, and test certificates.

Brand Advantages: Why Choose the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

The 336D Excavator Hydraulic Pump — Heavy Duty CAT Replacement — combines compatibility, tested performance, and global support. Key brand advantages include:

- Engineered or specified to fit CAT 336D machines for a direct-fit replacement.

- Available in OEM and High Quality aftermarket options to suit budgets and uptime needs.

- Designed for high-pressure, heavy-duty operations with improved hydraulic flow characteristics.

- Rigorously tested to ensure durability under construction and mining conditions.

- Global shipping and responsive customer service to minimize downtime.

FAQ — Frequently Asked Questions

Q: Can I replace my CAT 336D pump with a generic aftermarket unit?

A: Yes, but choose a reputable aftermarket supplier and ensure exact specification and fitment. High Quality aftermarket pumps can meet or exceed OEM performance when matched correctly.

Q: How long should a hydraulic pump last on an excavator?

A: With proper maintenance, correct fluid, and proper operating practices, a high-quality pump can last several thousand hours. Life expectancy varies by duty cycle and operating conditions.

Q: What causes pump cavitation and how do I prevent it?

A: Cavitation is caused by air or vapor bubbles forming in the suction line due to low inlet pressure or clogged suction filters. Prevention includes maintaining correct fluid levels, using the right oil viscosity, and ensuring suction piping is unobstructed.

Q: Is it necessary to replace hoses when replacing the pump?

A: Not always, but inspect hoses and fittings and replace any that show wear, cracks, or swelling. Replacing hoses proactively can prevent future failures after pump installation.

Q: Do aftermarket pumps void the excavator's warranty?

A: Using aftermarket parts may affect warranty coverage depending on the original equipment manufacturer's policies. Always check your machine's warranty terms.

Contact & Where to Buy — Next Steps

If you need assistance selecting a replacement hydraulic hydraulic pump for your CAT 336D, our specialists can help with fit verification, parts options (OEM or High Quality aftermarket), and shipping logistics. Contact our sales and technical support to check availability, request a quote, or schedule installation support. View the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement on our product page or reach out for an expedited quote and global shipping options.

Authoritative References

Where to Buy excavator parts in China

Preventive Maintenance Schedule for Excavator Engines

Comparing Heavy Duty CAT Replacement Hydraulic Pumps

How to Choose the Right Excavator Parts for Your Machine — Practical Guide

FAQ

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -