jackhuang5919@gmail.com

Key Features to Look for in a 336D Hydraulic Pump

- Selecting the Right Hydraulic Pump for Heavy Excavators

- Understanding the role of a hydraulic pump

- Key operational metrics: pressure, flow, and displacement

- Critical Technical Features to Inspect

- Material quality and internal machining

- Seals, bearings, and contamination resistance

- Hydraulic efficiency and heat management

- Fitment, Compatibility, and Installation Considerations

- Direct fit vs. adaptation

- OEM vs. High Quality Aftermarket: practical comparison

- Testing, Standards, and Warranty — what to verify

- Manufacturer testing and certification

- Standards and regulatory references

- Warranty and after-sales support

- Maintenance, Diagnostics, and Troubleshooting

- Preventive maintenance checklist

- Common failure modes and diagnostics

- When to replace vs rebuild

- Buying Guide and Practical Recommendations

- Checklist before purchase

- Installation best practices

- Operational tips to extend pump life

- Frequently Asked Questions (FAQ)

- Q: How do I know if my 336D hydraulic pump needs replacing?

- Q: Is OEM always better than aftermarket for hydraulic pumps?

- Q: What filtration level should I maintain for a 336D hydraulic system?

- Q: Can I install a superior-rated pump (higher pressure) on my 336D?

- Q: Where can I get replacement parts and service for a 336D hydraulic pump?

This concise guide helps fleet managers, mechanics, and equipment owners identify the most important attributes of a hydraulic pump for the CAT 336D excavator. It provides practical, actionable criteria—pressure and flow specs, displacement, material and seal quality, contamination control (ISO-aligned), installation compatibility, and maintenance best practices—to ensure uptime, safe operation, and long service life. Use this as your checklist when choosing the right 336D hydraulic pump—OEM or High Quality aftermarket.

Selecting the Right Hydraulic Pump for Heavy Excavators

Understanding the role of a hydraulic pump

A hydraulic pump is the heart of the excavator's hydraulic system. It converts mechanical energy from the engine into hydraulic flow and pressure that actuates the boom, stick, bucket, swing, and travel motors. For a machine like the CAT 336D, the pump must deliver consistent high-pressure performance while tolerating continuous heavy-duty cycles without overheating or cavitation. Learn the operational demands of your machine and match pump specifications accordingly. For general pump types and principles, see the hydraulic pump overview on Wikipedia (Wikipedia).

Key operational metrics: pressure, flow, and displacement

Two specifications define pump performance: maximum working pressure (psi or bar) and flow rate (liters per minute or gallons per minute). Displacement (cc/rev or in3/rev) determines how much fluid the pump moves per revolution and influences torque requirements and engine loading. For a 336D excavator hydraulic pump, prioritize pumps rated for high-pressure heavy-duty operation and matched flow curves to the hydraulic system to avoid stalling or excessive heat buildup.

Critical Technical Features to Inspect

Material quality and internal machining

Durable materials and precise machining reduce wear, prevent scoring, and maintain close tolerances critical for volumetric efficiency. Look for hardened components, quality alloys for gears or pistons, and low-porosity cast housings. These features extend service intervals and improve resilience in construction environments where shock loads and particulate contamination are common.

Seals, bearings, and contamination resistance

High-quality elastomers and bearings designed for elevated temperatures and hydraulic fluids provide leak resistance and long life. Contamination is a leading cause of pump failure—follow ISO 4406 contamination codes and filtration recommendations. For an industry standard on contamination control, see ISO 4406 information (ISO). Ensure the hydraulic pump design minimizes dead volume and includes robust suction ports and integrated pressure relief to reduce cavitation risk.

Hydraulic efficiency and heat management

High volumetric and mechanical efficiency reduce fuel consumption and heat generation. Efficient pumps maintain cooler oil temperatures under peak loads, reducing oxidation and seal degradation. Evaluate manufacturer test curves and efficiency maps to compare expected in-field performance.

Fitment, Compatibility, and Installation Considerations

Direct fit vs. adaptation

Whenever possible, select a direct-fit replacement. The 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement is engineered as a direct fit for CAT 336D excavators, reducing installation time and the risk of misalignment-related failures. Direct-fit pumps preserve factory mounting points, shaft spline sizes, and port locations, which keeps hydraulic line routing and couplings intact.

OEM vs. High Quality Aftermarket: practical comparison

OEM pumps are built to original specifications and often come with manufacturer-backed warranties. High Quality aftermarket pumps can match or exceed OEM performance at lower cost, but quality varies by vendor. Investigate material certificates, test reports, and customer reviews before selecting an aftermarket option.

| Feature | OEM Pump | High Quality Aftermarket Pump |

|---|---|---|

| Fitment | Guaranteed direct fit for CAT 336D | Often direct fit; verify mount and shaft specs |

| Materials & Tolerances | Made to original spec; controlled tolerances | Can equal or exceed OEM; dependent on supplier QA |

| Price | Higher | Lower to comparable |

| Warranty & Support | Manufacturer warranty and dealer support | Varies; choose reputable aftermarket brand |

| Testing | Factory testing to machine standards | Independent testing possible; ask for test results |

The product we provide—336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement—is available in both OEM and high-quality aftermarket versions. It offers direct-fit compatibility, high-pressure performance for heavy-duty operations, smooth hydraulic flow, and rigorous testing for quality and durability. Below is the product’s official description for quick reference:

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Testing, Standards, and Warranty — what to verify

Manufacturer testing and certification

Ask for test certificates showing pressure testing, leakage, volumetric efficiency, and noise/temperature measurements. Reputable vendors provide test runs and performance curves. Some suppliers provide end-of-line testing reports or traceability documents for critical parts.

Standards and regulatory references

Look for pumps built or tested against recognized industry standards. For hydraulic cleanliness and contamination control, reference ISO 4406. For industry trends and equipment guidance, the Association of Equipment Manufacturers (AEM) provides resources for heavy equipment users (AEM). For original equipment specifications and service documents, refer to Caterpillar’s official resources and manuals (Caterpillar).

Warranty and after-sales support

A solid warranty and responsive technical support reduce risk. OEM parts typically include factory warranties and dealer networks, while high-quality aftermarket suppliers may offer competitive warranties—check terms for coverage on failure modes (manufacturing defects vs wear-and-tear). Ensure the vendor provides parts availability and global shipping if you operate internationally.

Maintenance, Diagnostics, and Troubleshooting

Preventive maintenance checklist

Routine maintenance extends pump life: maintain clean hydraulic fluid, change filters at intervals aligned with site contamination levels, check suction strainers, maintain cooling systems, and follow torque and alignment specs during installation. Use oil analysis and ISO contamination counts to set filter change intervals.

Common failure modes and diagnostics

Watch for these signs of pump issues: reduced hydraulic speed (low flow), unusual noise (cavitation or bearing failure), overheating, erratic spool movement, and external leaks. Diagnose by checking fluid level and condition, filter condition, suction line kinks, air ingress, and pressure relief settings. Quick intervention prevents secondary damage to valves and actuators.

When to replace vs rebuild

Minor wear or seal failure may be addressed with rebuild kits; however, extensive scoring, rotor/cam damage, or bearing failure usually justify full replacement. Consider downtime cost, total rebuild cost, and expected remaining life. A brand-new direct-fit pump often restores original performance most quickly and predictably, while a professional rebuild can be cost-effective if performed by a certified shop using OEM parts.

Buying Guide and Practical Recommendations

Checklist before purchase

1) Confirm exact machine serial number and pump part number to ensure direct fit. 2) Request test reports and warranty terms. 3) Verify material specs and sealing compounds for your operating temperatures and hydraulic fluid. 4) Confirm shipping lead time and after-sales support. 5) If choosing aftermarket, insist on sample pressure/flow curves and customer references.

Installation best practices

Always follow torque specs, alignment procedures, and fluid bleeding steps specified by the machine manual. Use clean tools and maintain a contamination-free environment during installation—cover open ports with caps and use lint-free towels. After installation, monitor for leaks, unusual vibrations, or pressure anomalies during the initial run-in period.

Operational tips to extend pump life

Maintain proper oil temperature and cleanliness, avoid repeated stalling under heavy loads, and allow cool-down periods where possible. Implement hydraulic fluid sampling and trending to detect early signs of wear or contamination.

Frequently Asked Questions (FAQ)

Q: How do I know if my 336D hydraulic pump needs replacing?

A: Common indicators include loss of hydraulic power or speed, rising oil temperature, excessive noise (whining or grinding), visible leaks, and erratic machine movements. Perform a basic diagnostic—check fluid level/condition, filters, relief valve settings, and suction line for air leaks. Persistent symptoms after these checks usually mean replacement or rebuild is required.

Q: Is OEM always better than aftermarket for hydraulic pumps?

A: Not always. OEM parts guarantee original fit and factory support, but High Quality aftermarket pumps can offer equal or better performance at lower cost. Evaluate supplier reputation, certifications, materials, and test data before deciding.

Q: What filtration level should I maintain for a 336D hydraulic system?

A: Aim to meet the cleanliness levels recommended by the machine manual, often expressed using ISO 4406 codes. Many heavy excavators require cleanliness around ISO 18/16/13 or better, depending on system sensitivity. Use particle counters and oil analysis to confirm.Reference: ISO 4406 summary (ISO 4406).

Q: Can I install a superior-rated pump (higher pressure) on my 336D?

A: Only if the rest of the hydraulic system (hoses, valves, cylinders, relief settings) can safely handle the increased pressure. Upgrading to a higher-pressure pump without adjusting system components can cause damage. Consult a hydraulic system engineer or the equipment manual.

Q: Where can I get replacement parts and service for a 336D hydraulic pump?

A: Purchase from authorized dealers, reputable aftermarket suppliers, or directly from OEM channels. For machine-specific guidance and parts compatibility, refer to Caterpillar's official resources (Caterpillar) and industry guidance from AEM (AEM).

Need the right pump for your CAT 336D? Contact our technical sales team for application verification, test reports, and quotes. View the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement product page or get support for ordering and installation. Reach out now for fast shipping and responsive service.

Contact / View Product: View product & support • Contact sales

Buying Guide: Where to Source Excavator Hydraulic Pumps

Troubleshooting engine assemblies: noise, smoke, and leaks

Procurement Checklist: 336D Excavator Hydraulic Pump Specs

Compatibility Guide: Doosan DX65 Hydraulic Pump Fitment

FAQ

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

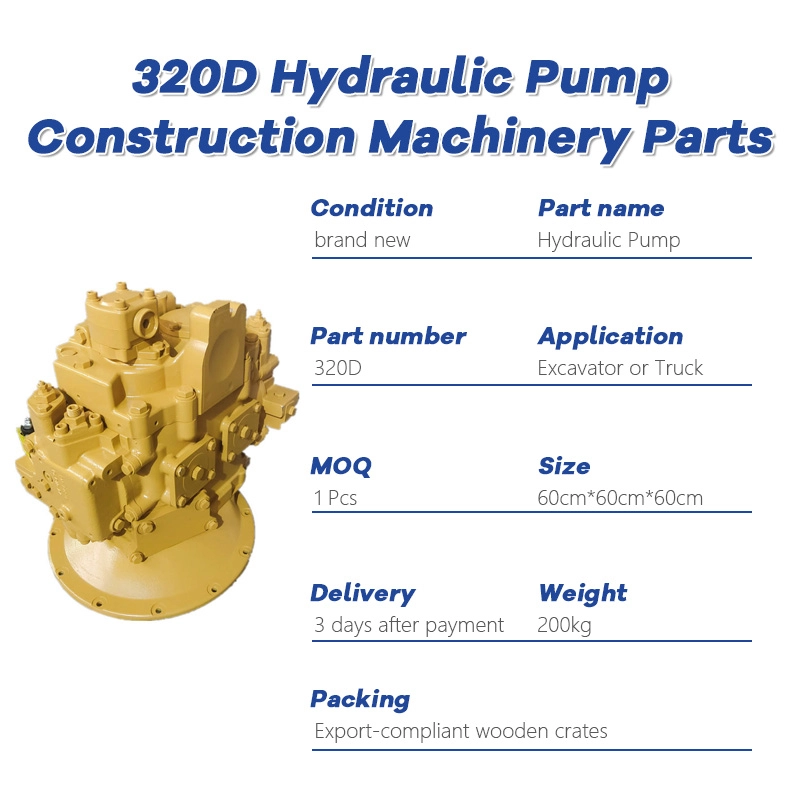

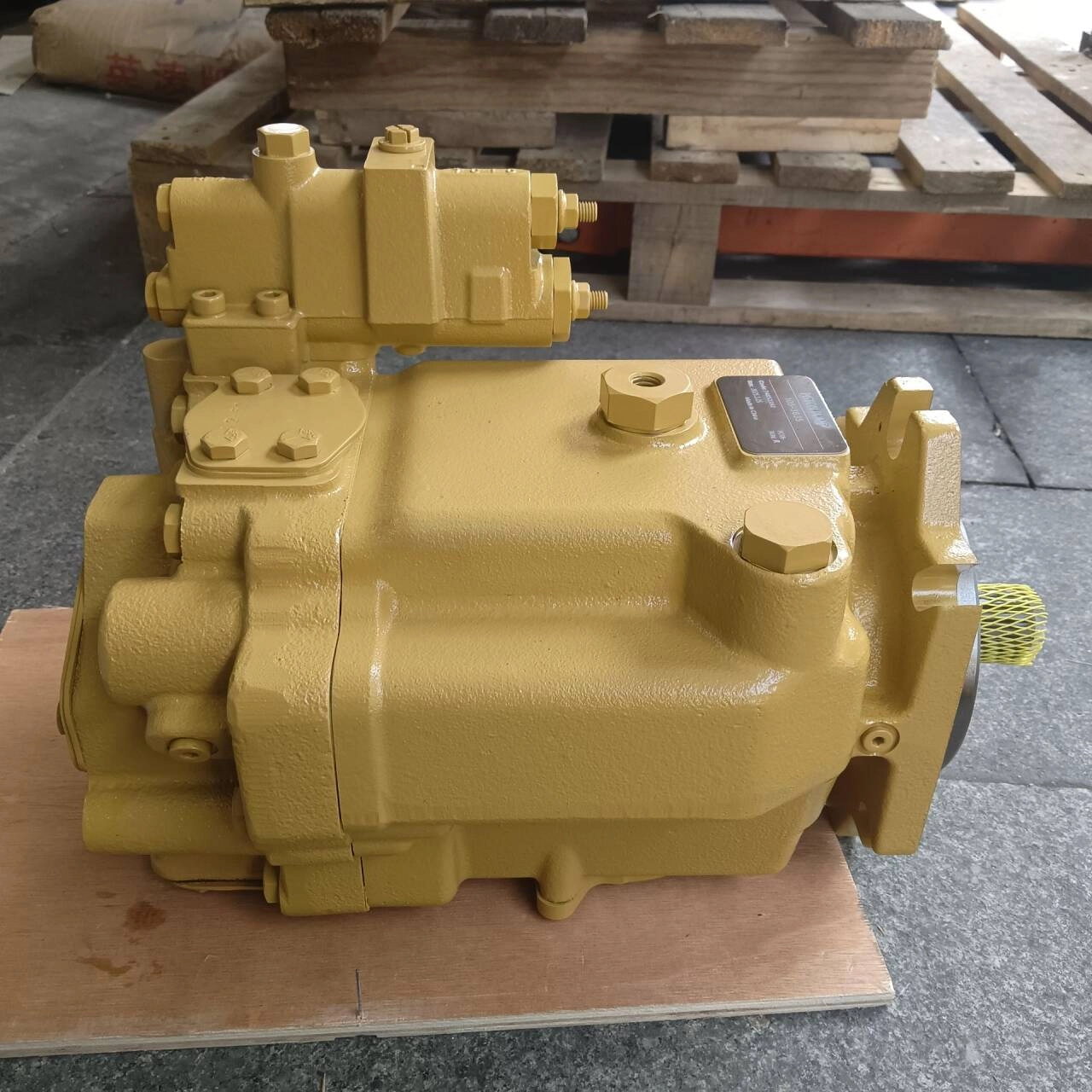

CAT 320D SBS120 Hydraulic Pump for Excavator | High Quality Replacement

This high-performance SBS120 hydraulic pump is specially designed for the CAT 320D excavator. Built with premium materials and precision manufacturing, it ensures reliable power delivery and long-lasting performance in tough construction environments. Ideal as an OEM replacement or aftermarket solution, this pump supports your hydraulic system with smooth, efficient operation.

-

Fits: Caterpillar 320D

-

Model: SBS120

-

Application: Excavator main hydraulic pump

-

Condition: New / Aftermarket available

-

Warranty: 6-12 months (optional)

-

Worldwide shipping available

-

CAT 980H Hydraulic Pump | Heavy-Duty Loader Replacement Part

The CAT 980H and 980G hydraulic pumps are engineered to provide optimal hydraulic power and durability for Caterpillar loaders. Built with premium materials and precision manufacturing, these pumps are ideal for OEM replacements and high-quality aftermarket upgrades. They ensure smooth hydraulic operation and reliable performance in demanding construction environments.

-

✔️ Direct fit for CAT 980H and 980G loaders

-

✔️ Available in OEM and aftermarket versions

-

✔️ High-pressure, heavy-duty hydraulic performance

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for durability and efficiency

-

✔️ Fast global shipping and excellent customer support

- 🛒 Order your CAT 980H & 980G Hydraulic Pump now!

📞 Contact us for bulk orders, technical support, or custom requests.

📦 Fast worldwide shipping | OEM & aftermarket options available -

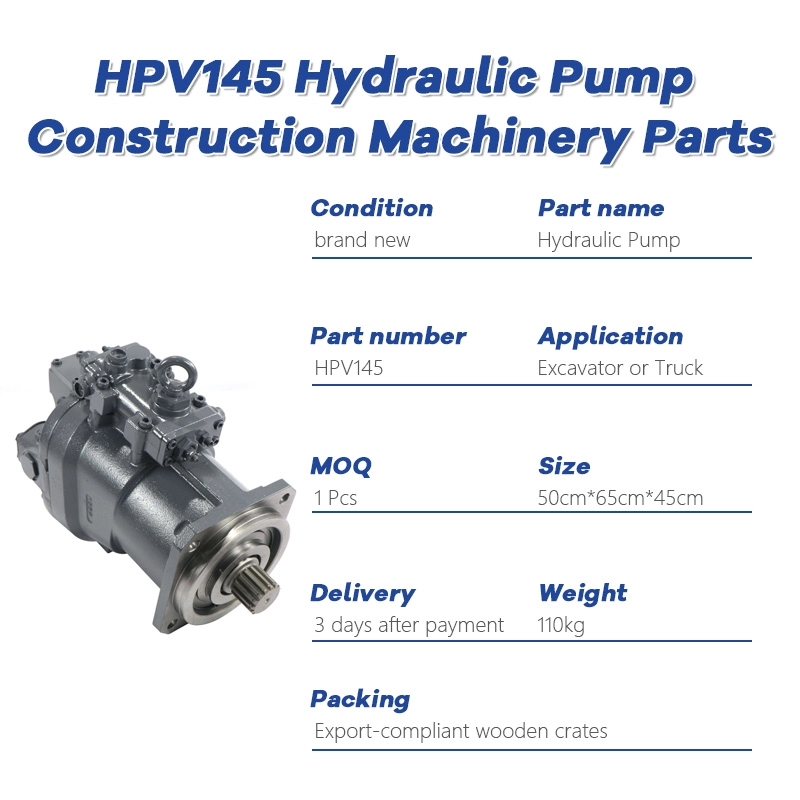

HPV145 Hydraulic Pump (Direct Injection) | Excavator Main Pump Replacement

The HPV145 single pump with direct injection technology is designed for excavators and heavy-duty machinery requiring precise hydraulic control and efficient power delivery. Combining advanced direct injection control with durable axial piston pump construction, this model ensures high performance, long service life, and reliable operation. Available in OEM and aftermarket versions, it is ideal for replacement or system upgrades.

-

✔️ Direct injection electronic control for precise hydraulic output

-

✔️ Suitable for excavators and various heavy machinery

-

✔️ High-pressure axial piston single pump design

-

✔️ OEM and aftermarket options for flexibility and cost-effectiveness

-

✔️ Robust materials and quality seals for long-term durability

-

✔️ Fast worldwide shipping and comprehensive technical support

- 🛒 Order Your HPV145 Direct Injection Single Pump Today – Precision, Durability & Performance

📞 Contact Us for pricing, availability, and technical support

🌍 Fast Global Shipping | OEM & Aftermarket | Secure Payment Options -

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -