jackhuang5919@gmail.com

Procurement Checklist: 336D Excavator Hydraulic Pump Specs

- Procurement Checklist: 336D Excavator Hydraulic Pump Specs

- Product Overview — 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- Why Hydraulic Pump Specs Matter When Procuring for CAT 336D

- Key Hydraulic Pump Specifications to Verify

- Compatibility Checklist — Ensuring a Direct Fit for CAT 336D

- OEM vs High Quality Aftermarket: Which 336D Hydraulic Pump to Buy?

- Testing, Quality Validation and Documentation

- Installation Best Practices for 336D Excavator Hydraulic Pumps

- Maintenance Tips to Maximize Pump Lifetime

- Procurement Step-by-Step Checklist (Quick Reference)

- Cost, Lead Time and Logistics Considerations for Bulk Procurement

- Brand Advantages — Why Choose 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

- FAQ — Common Questions About 336D Hydraulic Pump Procurement

- Q: How do I identify the correct pump model for my CAT 336D?

- Q: Can I replace an OEM pump with a High Quality aftermarket pump?

- Q: What are the signs of hydraulic pump failure?

- Q: Is hydraulic fluid type critical for pump life?

- Q: Do pumps come pre-tested?

- Contact & Purchase CTA

- Authoritative References and Further Reading

- Final Recommendations

- Related Materials

Procurement Checklist: 336D Excavator Hydraulic Pump Specs

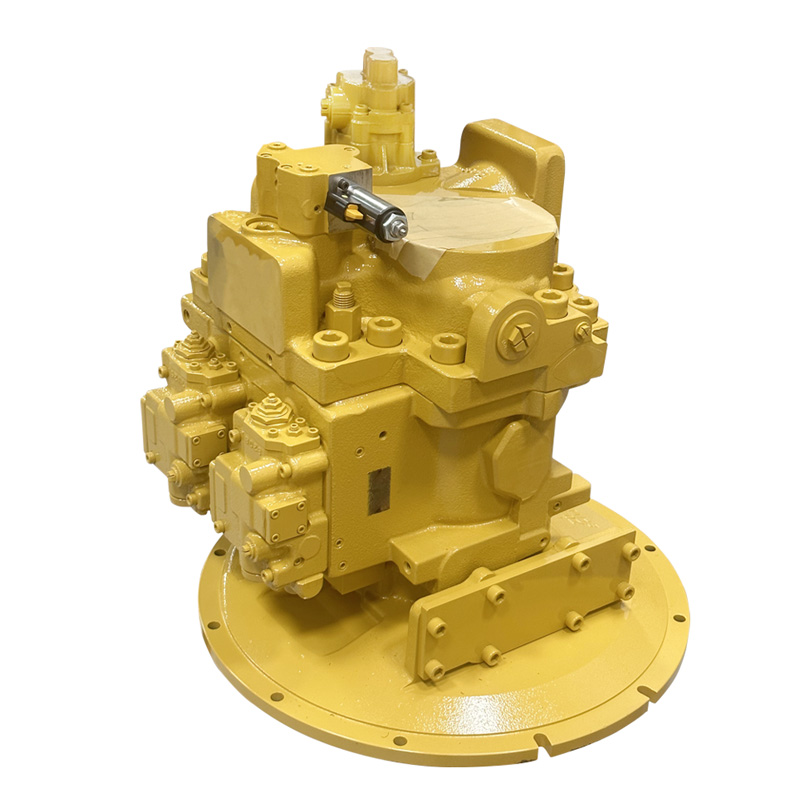

Product Overview — 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Why Hydraulic Pump Specs Matter When Procuring for CAT 336D

Choosing the correct hydraulic pump is not just about physical fit — hydraulic pumps determine system pressure capability, flow rate, efficiency and ly the excavator's performance and operating cost. A pump mismatch can cause poor digging speed, overheating, excessive wear, or even catastrophic failure. Therefore, understanding the key specifications and quality measures is essential before purchase.

Key Hydraulic Pump Specifications to Verify

Before ordering a 336D hydraulic pump, verify the following critical specs to ensure compatibility and performance:

- Displacement (cc/rev or in³/rev) — Determines how much oil the pump moves per revolution. Match to the engine speed and actuator requirements to achieve intended cylinder speeds.

- Maximum Operating Pressure (bar / psi) — Ensure the pump rating meets or exceeds the machine’s system pressure. For heavy-duty CAT excavators, verify high-pressure capability for breakout forces.

- Flow Rate (L/min or GPM) at specified RPM — Flow curve should match hydraulic circuit demands across operating RPM ranges.

- Drive Shaft Type and Spline Details — Count splines, measure diameter, and confirm keyway or pilot fit to avoid coupling problems.

- Mounting Flange and Bolt Pattern — Direct-fit mounting reduces adapter cost and downtime.

- Port Type & Orientation (SAE/Metric; Inlet/Outlet sizes) — Incorrect ports require adapters or new hoses.

- Rotation (clockwise/ccw) — Pump rotation must match the machine’s hydraulic drive direction.

- Weight, Dimensions & Center of Gravity — Impacts handling and installation clearances.

- Materials & Coatings — High-wear components, bearing materials, and corrosion-resistant coatings extend life.

- Part Numbers & Cross References — Verify OEM part numbers and aftermarket cross-reference lists to prevent ordering wrong items.

Compatibility Checklist — Ensuring a Direct Fit for CAT 336D

To confirm compatibility with a CAT 336D excavator, follow these practical steps:

- Locate the existing pump’s model and part number stamped on the housing; document serial numbers.

- Confirm spline count, shaft diameter and key orientation against technical drawings or the new pump datasheet.

- Compare mounting flange dimensions and bolt patterns to ensure bolt holes line up precisely.

- Check port thread size and orientation; match hose fittings and adapters if necessary.

- Verify rotation and displacement to match system design and pump pairing (if multiple pumps are used).

- When in doubt, consult the equipment’s service manual or the supplier’s fitment guide.

OEM vs High Quality Aftermarket: Which 336D Hydraulic Pump to Buy?

One of the most frequent procurement decisions is whether to purchase an OEM pump or a High Quality aftermarket replacement. Each has trade-offs in price, warranty, availability and quality control. Use the table below for a direct comparison.

| Attribute | OEM CAT Pump | High Quality Aftermarket Pump |

|---|---|---|

| Fit & Compatibility | Guaranteed direct fit; engineered to spec | Many are direct-fit; verify part cross-reference |

| Quality Control | Manufacturer QA and traceability | High-quality brands offer comparable QC; varies by maker |

| Price | Typically higher | Often lower cost; better value options available |

| Warranty | Robust OEM warranty | Competitive warranties from reputable suppliers |

| Availability & Lead Time | May have longer lead times depending on supply chain | Often faster or locally stocked |

| After-sales Support | Manufacturer network and technical resources | Supplier-dependent; choose vendors with good service |

Testing, Quality Validation and Documentation

Rigorously testing the pump before installation reduces field failures. Look for suppliers that provide:

- Test certificates showing pressure, flow and leakage results.

- Material traceability and batch numbers for critical components.

- Dimensional drawings and datasheets with clear tolerances.

- Manufacturer service manuals and recommended maintenance intervals.

Additionally, confirm any conformity to industry standards such as SAE shaft/port standards, and cleanliness protocols (ISO hydraulic fluid cleanliness practices) when relevant.

Installation Best Practices for 336D Excavator Hydraulic Pumps

Proper installation protects the new pump and ensures maximum lifespan:

- Use clean work areas and keep all hydraulic openings capped until final hose/coupling fitment.

- Flush the hydraulic system or thoroughly filter return lines if contamination is suspected.

- Torque mounting bolts to manufacturer specifications to avoid housing distortion.

- Prime the pump per the supplier’s instructions — many pumps require specific priming procedures to avoid dry starts.

- Verify system pressure settings, relief valves, and filtration after installation.

- Run a staged break-in: low-load start, check for leaks and abnormal noises, then gradually move to normal operation.

Maintenance Tips to Maximize Pump Lifetime

Routine care will keep the hydraulic pump performing reliably:

- Follow OEM or supplier-recommended oil change intervals and use the specified hydraulic fluid viscosity and anti-wear additives.

- Monitor oil cleanliness—install particle counters or sample and test regularly.

- Replace suction screens, return-line filters and breather elements per schedule.

- Check pump mounting and shaft couplings for signs of misalignment and tension-related wear.

- Record runtime hours and operating conditions to predict end-of-life and plan replacements.

Procurement Step-by-Step Checklist (Quick Reference)

Use this concise checklist during procurement to reduce errors and downtime:

- Record existing pump model, part number, serial number, spline count and rotation.

- Confirm pump displacement, max pressure and flow requirements for your 336D configuration.

- Decide OEM vs aftermarket based on budget, lead time and warranty needs.

- Request datasheets and test certificates from the supplier.

- Verify mounting, shaft, and port compatibility (measure where necessary).

- Check stock availability and lead time; order spare parts (seals, O-rings) as needed.

- Plan installation window and ensure filtration/priming materials are on hand.

- Confirm warranty, returns policy, and after-sales technical support contact details.

Cost, Lead Time and Logistics Considerations for Bulk Procurement

For fleets and contractors, total cost of ownership matters more than unit price. Consider:

- Volume discounts and consignment stocking to keep downtime low.

- Warranty terms that reduce long-term maintenance expense.

- Local stocking or expedited shipping options to meet emergency needs.

- Import compliance and spare-part documentation for cross-border shipments.

Brand Advantages — Why Choose 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement

Our 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement is engineered to meet the rigors of construction, mining and heavy earthmoving. Key brand advantages include:

- Direct-fit design that minimizes installation time and avoids adapter modifications.

- Dual availability: OEM-level components for customers requiring factory-spec parts and High Quality aftermarket options for cost-sensitive operations.

- Pressure-tested and quality-checked with documented test reports to prove performance under rated conditions.

- Global shipping and responsive support to coordinate emergency replacements and technical guidance.

- Comprehensive warranty and clear replacement policies to protect fleet uptime.

FAQ — Common Questions About 336D Hydraulic Pump Procurement

Q: How do I identify the correct pump model for my CAT 336D?

A: Locate the part number and serial stamp on the current pump housing. Cross-reference that number with the service manual or supplier’s fitment guide. Measure shaft splines and flange dimensions if the tag is missing.

Q: Can I replace an OEM pump with a High Quality aftermarket pump?

A: Yes — reputable High Quality aftermarket pumps are designed to match OEM specs. Verify dimensional fit, shaft spline, displacement and rotation. Review test documentation and warranty before purchase.

Q: What are the signs of hydraulic pump failure?

A: Common signs include reduced lifting/digging speed, unusual noises (knocking, whining), overheating, increased fluid contamination, and visible leaks. Address early to limit secondary damage to motors and valves.

Q: Is hydraulic fluid type critical for pump life?

A: Absolutely. Use the viscosity and specification recommended by Caterpillar or the pump supplier, and maintain cleanliness standards. Contaminated or incorrect fluids majorly shorten pump life.

Q: Do pumps come pre-tested?

A: Many reputable suppliers ship pumps with factory test certificates showing pressure, flow and leakage results. Request these documents and retain them with service records.

Contact & Purchase CTA

When following the procurement checklist for 336D excavator hydraulic pump specs, it’s essential to compare options by comparing heavy duty CAT replacement hydraulic pumps to ensure you select parts that match performance and reliability requirements.If you are ready to buy or need assistance confirming fitment, contact our support team or view the product page for the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement:

- View product details & order

- Contact parts support: parts@yourcompany.com

- Phone: +1-800-XXX-XXXX (support available 24/7 for urgent replacements)

Authoritative References and Further Reading

For technical standards, background and official OEM information consult these resources:

- Hydraulic pump — Wikipedia

- Caterpillar — Official website

- CAT Parts — Official parts portal

- ISO 4406 — Hydraulic fluid contamination (overview)

- Hydraulics & Pneumatics — Industry articles and best practices

Final Recommendations

Procurement of a CAT 336D hydraulic pump should be systematic: verify specs, insist on test documentation, plan installation and filtration, and select a supplier who provides clear warranties and responsive support. Whether you opt for OEM or a High Quality aftermarket pump, careful verification using this checklist will reduce downtime and total cost of ownership while keeping your 336D excavator working at peak performance.

Related Materials

Keep the following on hand during procurement and installation: service manual for CAT 336D, pump datasheets, test certificates, replacement seal kits, and torque specifications.

Excavator Engine Diagnostics: Tools and Techniques

How Cold Starts Affect Excavator Engine Performance

Emissions and Regulations: ZAX870-5G 6WG1 Compliance Tips

Compatibility Matrix: 336D Pump Fitment and Performance Factors

FAQ

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -