jackhuang5919@gmail.com

Ultimate Guide to Excavator Parts: Identification, Maintenance, & Sourcing for 2026

This comprehensive guide serves as the definitive resource for excavator parts in 2026. It covers the core anatomy of excavators, including detailed breakdowns of the undercarriage, hydraulic systems, and attachments. Readers will gain expert insights into maintenance schedules, identifying wear patterns, and sourcing strategies (OEM vs. aftermarket). The article also explores future trends like smart components and electrification, providing actionable advice for operators and buyers.

- Introduction: Navigating the World of Excavator Parts

- The Core Anatomy of an Excavator: Main Sections and Their Components

- The Undercarriage: Foundation of Mobility

- The House/Upper Structure: Power, Control, and Stability

- The Working Group: Boom, Arm, and Bucket

- Beyond the Basics: Specialized Excavator Attachments

- Commonly Replaced Excavator Parts: Wear & Lifespan

- Undercarriage Wear

- Hydraulic System Health

- Ground Engaging Tools (GET)

- A Buyer's Guide to Excavator Parts: Sourcing Smartly

- Maximizing Excavator Part Lifespan Through Maintenance

- The Future of Excavator Parts: Innovation and Technology

- Frequently Asked Questions

- What are the most critical excavator parts for daily operation?

- How often should excavator hydraulic filters be replaced?

- What is the difference between OEM and aftermarket excavator parts?

- How can I identify the correct replacement part for my excavator?

- What are common signs of wear in excavator undercarriage components?

- Can I use used excavator parts?

- What role does the counterweight play in an excavator?

- Are there eco-friendly excavator parts options available?

- References

Introduction: Navigating the World of Excavator Parts

Excavators are the backbone of modern construction, mining, and forestry industries. Their ability to perform heavy-duty tasks—from digging trenches to demolishing structures—relies entirely on the synergy of thousands of specialized components. For operators, fleet managers, and parts purchasers, a surface-level understanding of these machines is no longer sufficient.

In 2026, the market for heavy machinery parts is evolving rapidly, driven by technological advancements and shifting supply chain dynamics. Whether you are troubleshooting a hydraulic failure or comparing excavator parts to determine the most reliable options, or looking for the best excavator parts to extend your machine's lifecycle, deep technical knowledge is your most valuable asset. This guide provides a "Skyscraper" level deep dive into excavator anatomy, offering a definitive reference for identification, maintenance, and smart sourcing strategies.

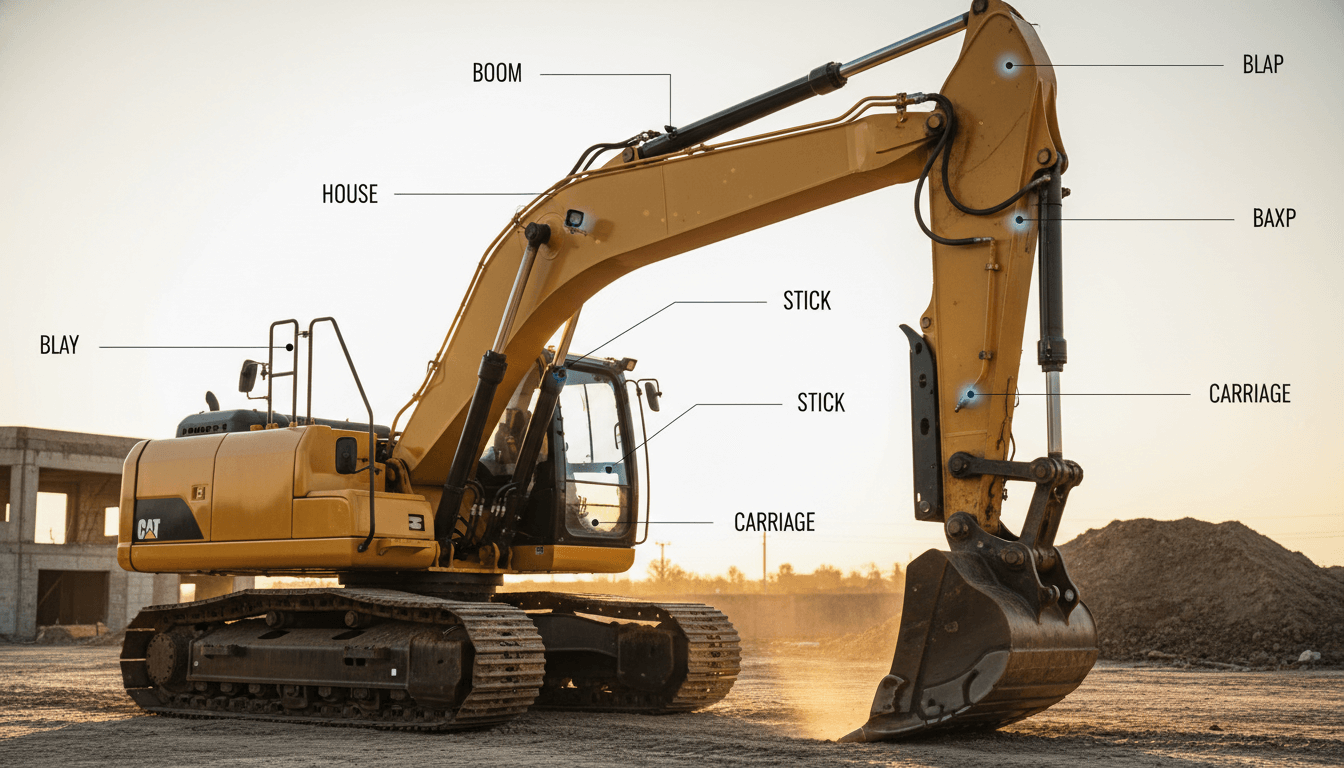

The Core Anatomy of an Excavator: Main Sections and Their Components

Understanding the distinct sections of an excavator is fundamental to diagnostics and procurement. The machine is generally divided into three main assemblies: the Undercarriage, the Upper Structure (House), and the Working Group.

The Undercarriage: Foundation of Mobility

The undercarriage is the most expensive operational component, often accounting for 50% of total maintenance costs over the machine's life. It supports the entire weight of the excavator and enables mobility over rough terrain.

· Tracks (Steel vs. Rubber): Steel tracks provide durability for harsh environments like quarries, while rubber tracks reduce ground disturbance on paved surfaces or finished lawns.

· Track Frame: The structural chassis that holds the moving parts.

· Rollers (Carrier & Track): Track rollers (bottom) support the machine's weight, while carrier rollers (top) prevent the track chain from sagging.

· Idlers: Located at the front, idlers maintain track tension and absorb shock loads. Improper tension is a leading cause of premature wear.

· Sprockets: Toothed wheels at the rear that engage the track links to drive the machine. "Shark-finning" on sprocket teeth is a key indicator of wear.

· Final Drives: Complex planetary gearboxes that convert high-speed hydraulic power into the high-torque rotation needed to move the tracks.

The House/Upper Structure: Power, Control, and Stability

This section sits atop the undercarriage and can rotate 360 degrees, allowing for versatile operation.

· Operator Cab: The command center featuring ergonomic controls, ROPS (Rollover Protective Structures), and FOPS (Falling Object Protective Structures) for safety.

· Engine: The primary power source, typically a diesel engine, though electric variants are gaining traction. It drives the hydraulic pumps.

· Hydraulic System: The "muscle" of the excavator. Key components include the Main Pump (converts mechanical energy to flow), Control Valves (direct flow to cylinders/motors), and Hydraulic Tank (reservoir).

· Swing Drive/Slewing Ring: A massive bearing and motor assembly that enables the house to rotate relative to the undercarriage.

· Counterweight: A heavy mass at the rear that balances the machine when lifting heavy loads, preventing tipping.

The Working Group: Boom, Arm, and Bucket

This assembly is responsible for the actual digging and lifting actions, defined by the International Organization for Standardization (ISO) 6015 standards for tool forces.

· Boom: The main angled arm attached to the house. Options include Mono Booms for general use and Articulated Booms for confined spaces.

· Arm (Stick/Dipper): Connects the boom to the bucket, providing reach and digging depth.

· Bucket: The ground-engaging tool. Variations include trenching, grading, and rock buckets.

· Cylinders: Hydraulic rams that actuate the boom, arm, and bucket. They operate on Pascal’s Law, where pressurized fluid generates linear force.

· Linkages & Pins: High-stress connection points that require daily greasing to prevent "slop" or play in the movement.

Beyond the Basics: Specialized Excavator Attachments

To maximize utility, modern excavators utilize a range of hydraulic attachments. As a trusted manufacturer of excavator parts, we see a high demand for components that support these versatile tools.

· Hydraulic Breakers: Used for demolition. Critical parts include the chisel (moil point), piston, and front head.

· Grapples: Hydraulic jaws for handling logs, scrap, or demolition debris.

· Augers: Drilling attachments for post holes. Key parts are the drive unit, flighting, and pilot teeth.

· Tiltrotators: An advanced "wrist" between the arm and bucket, allowing the attachment to tilt and rotate, significantly increasing precision.

Commonly Replaced Excavator Parts: Wear & Lifespan

Proactive replacement of wear parts prevents catastrophic failure. Recognizing the signs of wear is a critical skill for any operator.

Undercarriage Wear

Abrasion is the enemy here. Track chains stretch over time as internal pins and bushings wear. Sprockets become pointed. Rollers can develop flat spots if they seize. Regular cleaning is essential; packed mud hardens and acts like a grinding paste.

Hydraulic System Health

Hydraulic Hoses degrade due to UV exposure and pressure spikes, leading to leaks. Seals inside cylinders can fail, causing "drift" (where the boom slowly drops). Filters are the first line of defense; clogged filters can cause pump cavitation, a destructive condition where air bubbles implode inside the pump.

Ground Engaging Tools (GET)

Bucket Teeth and Cutting Edges are sacrificial parts. Using the wrong tooth material (e.g., using a general-purpose tooth on abrasive granite) will result in rapid rapid wear. Tungsten carbide coatings are often used for extreme durability.

A Buyer's Guide to Excavator Parts: Sourcing Smartly

Choosing between OEM (Original Equipment Manufacturer) and aftermarket parts is a major decision impacting budget and performance.

· OEM Parts: Sourced directly from the brand (e.g., Cat, Komatsu). They guarantee perfect fitment and usually come with a robust warranty but at a premium price.

· Aftermarket Parts: Produced by third-party manufacturers. Quality varies widely. High-quality aftermarket parts can match OEM performance at a fraction of the cost, while low-quality options may fail prematurely.

Sourcing Tips:

1. Verify Compatibility: Always source using the machine's Serial Number and the specific Part Number.

2. Check Materials: For undercarriage parts, ensure high-grade steel (e.g., induction-hardened boron steel) is used.

3. Supplier Reputation: Look for suppliers who offer technical support and warranties.

Maximizing Excavator Part Lifespan Through Maintenance

According to industry data, neglected maintenance is the leading cause of unscheduled downtime. Implementing a rigorous schedule is non-negotiable.

· Daily: Check fluid levels (engine oil, hydraulic fluid, coolant). Grease pivot points. Clean the undercarriage of mud and debris.

· Weekly: Check track tension (sag). Inspect hydraulic hoses for rubbing or cracking.

· Monthly: Check final drive oil levels. Inspect air filters. Sample hydraulic fluid for analysis.

Advanced diagnostics are becoming standard. Many modern excavators feature telematics that alert fleet managers to fault codes before a physical failure occurs.

The Future of Excavator Parts: Innovation and Technology

As we look toward 2026, the industry is shifting. We are seeing a rise in customized excavator parts designed for specific applications, alongside broader technological trends.

· Smart Components: Hydraulic cylinders with integrated position sensors are enabling semi-autonomous digging.

· Electrification: Electric excavators require different maintenance protocols, replacing diesel filters and belts with battery management systems and electric motors.

· Sustainability: There is a growing market for remanufactured parts, which offer a greener alternative to buying new without sacrificing quality.

Frequently Asked Questions

What are the most critical excavator parts for daily operation?

The engine (power source), hydraulic pump (flow generation), main control valve (flow direction), and the undercarriage (mobility) are the most critical systems. Failure in any of these will render the machine inoperable.

How often should excavator hydraulic filters be replaced?

Standard intervals are typically every 500 to 1,000 operating hours. However, always refer to the specific service manual for your machine, as harsh operating environments (dust, extreme heat) may require more frequent changes.

What is the difference between OEM and aftermarket excavator parts?

OEM parts are made by the machine's original manufacturer and guarantee exact specifications. Aftermarket parts are made by third parties; while often cheaper, buyers must carefully vet the supplier to ensure the material quality matches OEM standards.

How can I identify the correct replacement part for my excavator?

The most reliable method is to use the Machine Serial Number and the specific Part Number found in the parts manual. Visual matching is risky due to subtle revision changes in manufacturing.

What are common signs of wear in excavator undercarriage components?

Look for "shark-fin" wear patterns on sprocket teeth, external wear on bushings (causing track stretch), flat spots on rollers, and loose track pads. Increased vibration during travel is also a key indicator.

Can I use used excavator parts?

Yes, used or "reconditioned" parts are a viable cost-saving strategy for major components like final drives or engines, provided they come from a reputable dealer and have been pressure-tested or inspected.

What role does the counterweight play in an excavator?

The counterweight offsets the weight of the boom, arm, bucket, and payload. Without it, the machine would tip forward when lifting heavy loads or digging at maximum reach.

Are there eco-friendly excavator parts options available?

Yes. The industry is seeing more remanufactured components (which save energy and raw materials) and the development of bio-degradable hydraulic fluids to reduce environmental impact in sensitive areas.

References

· Wikipedia: Excavator Anatomy and Terminology

· iTeh Standards: ISO 6015 Earth-moving machinery — Hydraulic excavators

· Heavy Vehicle Inspection: Excavator Maintenance Checklist

· Construction Briefing: Seven construction technology trends for 2026

FAQ

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -