jackhuang5919@gmail.com

Procurement Guide: Specifying Isuzu D1703 Engine Assemblies

- Procurement Guide: Specifying Isuzu D1703 Engine Assemblies

- Overview — Engineered Diesel Solutions for Heavy Machinery

- Why Choose Engineered Diesel for Heavy Equipment?

- Business Intent: Reduce downtime and optimize fuel use with engineered diesel

- Understanding the Isuzu D1703 Diesel Engine Assembly

- Product Focus: Isuzu D1703 Engine Assembly

- Performance and Reliability Considerations

- : Maximize uptime and lifecycle value

- Compatibility and Installation Requirements

- : Reduce retrofit complexity and integration cost

- Technical Specification Template for Purchase Orders

- : Create unambiguous procurement specs

- Procurement Best Practices: OEM vs Remanufactured vs Aftermarket

- : Balance upfront cost against lifecycle risk

- Inspection, Testing, and Acceptance Criteria

- : Prevent receiving defective assets and reduce commissioning time

- Cost Comparison: Lifecycle View (Qualitative)

- : Make procurement decisions based on total cost of ownership

- Supplier Evaluation and Risk Management

- : Validate supplier capability and reduce supply chain disruption

- Brand Advantages: Why Isuzu for Engineered Diesel Needs

- : Leverage brand strength to reduce operational risk

- Common Pitfalls to Avoid

- : Avoid costly integration and operational issues

- FAQ — Frequently Asked Questions

- Q: Is the Isuzu D1703 suitable for excavators used in dusty environments?

- Q: What warranty and support options are typical for a D1703 assembly?

- Q: Can the D1703 meet emissions requirements in regulated markets?

- Q: What spare parts should be procured with the engine?

- Next Steps & Call to Action

- Contact us to view product details or request a quote

- Authority and References

- Trusted sources for further reading

Procurement Guide: Specifying Isuzu D1703 Engine Assemblies

Overview — Engineered Diesel Solutions for Heavy Machinery

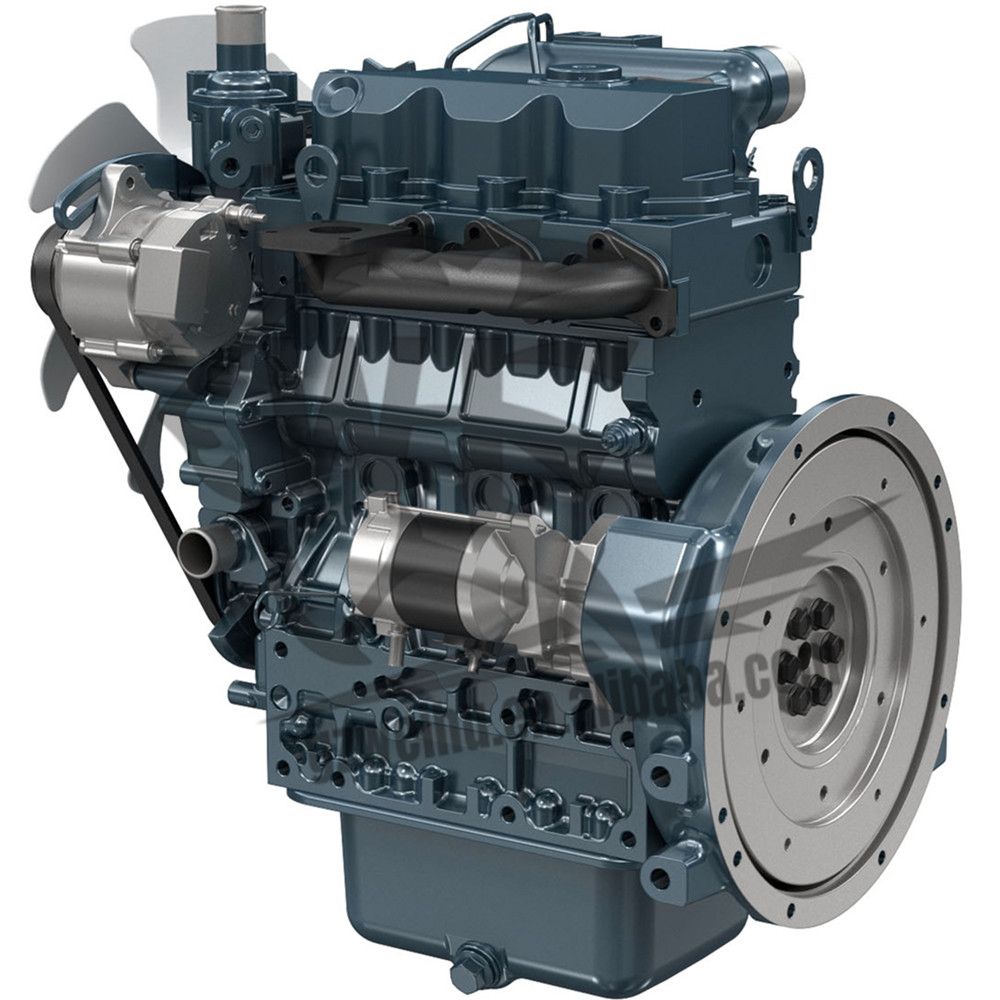

The Isuzu D1703 Diesel Engine | High-Performance Engine Assembly for Heavy Machinery is an engineered diesel powerplant purpose-built for demanding environments. The D1703 is a high-performance, durable, and reliable diesel engine designed for heavy-duty machinery, including excavators, construction equipment, and industrial applications. Manufactured by Isuzu, this engine combines proven engineering with strong fuel efficiency and long service life, making it an excellent selection for procurement teams focused on uptime and total cost of ownership. After confirming specifications and configurations, buyers should evaluate long-term economics through a total cost of ownership analysis for engineered diesel Isuzu D1703 engines.

Why Choose Engineered Diesel for Heavy Equipment?

Business Intent: Reduce downtime and optimize fuel use with engineered diesel

Engineered diesel engines are developed specifically for heavy-duty cycles, frequent idling, high torque demands, and extended operating hours common in construction and industrial applications. For procurement managers, the benefits are practical and measurable:

- Durability: Components are specified for high-load longevity, reducing unscheduled replacements.

- Fuel economy: Optimized combustion and injection systems lower fuel consumption per operating hour.

- Serviceability: Standardized service intervals and available OEM service parts simplify maintenance planning.

- Regulatory compliance: Engineered designs can be configured to meet applicable emissions regulations in the region of operation.

Understanding the Isuzu D1703 Diesel Engine Assembly

Product Focus: Isuzu D1703 Engine Assembly

The Isuzu D1703 is positioned as a compact, high-performance diesel engine assembly used in a variety of small-to-medium excavators, compact construction equipment, and industrial machines. Key attributes procurement teams commonly evaluate include reliability under continuous duty, parts availability, and compatibility with existing vehicle architectures.

Product Description: The D1703 Engine is a high-performance, durable, and reliable diesel engine designed for heavy-duty machinery, including excavators, construction equipment, and industrial applications. Manufactured by Isuzu, this engine combines cutting-edge technology with exceptional power, fuel efficiency, and longevity, making it the ideal choice for businesses that require consistent and efficient engine performance in demanding environments.

Performance and Reliability Considerations

: Maximize uptime and lifecycle value

When specifying the D1703 assembly, procurement must evaluate expected duty cycles, operating environment (temperature, dust, altitude), and duty factors (how many hours per day and year). Key reliability checkpoints:

- Duty rating: Confirm continuous vs intermittent duty suitability.

- Cooling system adequacy: Verify radiator sizing and coolant routing for excavator layouts.

- Air intake and filtration: Ensure filtration meets dusty-site requirements.

- Aftertreatment needs: For regulated regions, confirm compatibility with emissions controls.

Compatibility and Installation Requirements

: Reduce retrofit complexity and integration cost

Specifying an engine assembly involves more than choosing a model. Consider mechanical mounts, flywheel housing orientation, torque curves, electrical integration (starter, alternator, ECU interfaces), fuel system fittings, and exhaust routing. A clear interface specification reduces change orders and downtime during installation.

Checklist for procurement specifications:

- Mounting pattern and dimensions

- Torque and power curve at rated RPM

- Electrical system voltage and connector types

- Fuel supply pressure and filter types

- Cooling inlet/outlet locations and flow rates

- Exhaust outlet position and backpressure tolerance

- Accessory drives and PTO options

Technical Specification Template for Purchase Orders

: Create unambiguous procurement specs

Provide suppliers with a clear technical specification document. Below is a condensed template of items to include in your PO or technical annex:

- Engine model and serial number range

- Guaranteed power and torque bands at specified RPM

- Fuel consumption or economy class (e.g., standard duty efficiency)

- Emissions certification target (if applicable)

- Warranty terms and coverage (hours, parts, labor)

- Spare parts kit and recommended spare parts list

- Acceptance tests: run-in hours, load tests, vibration limits

- Documentation: OEM manual, wiring diagrams, maintenance schedules, parts catalog

Procurement Best Practices: OEM vs Remanufactured vs Aftermarket

: Balance upfront cost against lifecycle risk

When buying engine assemblies, consider three primary options:

- New OEM assemblies: Highest upfront cost, full OEM warranty, guaranteed fit, best for minimizing integration risk.

- Remanufactured OEM: Lower cost, good warranty if reman is OEM-certified. Useful where budgets are constrained but reliability is still crucial.

- Aftermarket: Lower cost but variable quality and spare part compatibility. Use only with strict vendor qualification and testing.

Procurement should require supplier quality certifications, traceability of core components, and a clear return/repair process for failures in warranty.

Inspection, Testing, and Acceptance Criteria

: Prevent receiving defective assets and reduce commissioning time

Include factory and site acceptance tests in the contract:

- Factory Acceptance Test (FAT): Visual inspection, leak checks, idle/run tests, full-load simulation where possible.

- Pre-shipment documentation: Serial numbers, test logs, calibration certificates.

- Site Acceptance Test (SAT): Installation check, integrated system run, full load verification, emissions check (if required).

- Vibration and noise checks: Ensure thresholds are met for operator comfort and component life.

Cost Comparison: Lifecycle View (Qualitative)

: Make procurement decisions based on total cost of ownership

The table below compares the Isuzu D1703 engine assembly against a generic competitor set using practical procurement metrics. Values are qualitative indicators to guide specification and supplier discussions.

| Metric | Isuzu D1703 (Engineered Diesel) | Generic Competitor |

|---|---|---|

| Initial Cost | Medium | Low–Medium |

| Fuel Efficiency | Good | Average |

| Parts Availability | High (OEM network) | Variable |

| Maintenance Complexity | Standardized, well-documented | May require custom solutions |

| Resale Value | Higher | Lower |

| Warranty & Support | Robust OEM options | Dependent on vendor |

Supplier Evaluation and Risk Management

: Validate supplier capability and reduce supply chain disruption

Key supplier evaluation criteria:

- OEM authorization or certification

- Quality management systems (ISO 9001 or equivalent)

- Traceability and serialisation of parts

- Local service network and spare parts lead times

- Financial stability and references from other heavy equipment buyers

Include contractual clauses for lead time penalties, quality acceptance, and spares provisioning for long-term support.

Brand Advantages: Why Isuzu for Engineered Diesel Needs

: Leverage brand strength to reduce operational risk

Isuzu's reputation in diesel engine design brings several procurement advantages:

- Global aftermarket and parts support reduces downtime risk.

- Established engineering means better-documented interfaces and predictable performance.

- Compliance expertise aids in navigating emissions and certification requirements.

- Wide OEM adoption ensures easier integration into many chassis and equipment platforms.

Common Pitfalls to Avoid

: Avoid costly integration and operational issues

Frequent mistakes procurement teams make include:

- Incomplete interface drawings that lead to on-site modifications.

- Failing to specify duty cycles or environmental conditions, resulting in undersized cooling or filtration.

- Choosing lowest initial cost without warranty and parts support analysis.

- Not planning spare parts and consumable provisioning ahead of delivery.

FAQ — Frequently Asked Questions

Q: Is the Isuzu D1703 suitable for excavators used in dusty environments?

A: Yes—when specified with appropriate heavy-duty air filtration and correctly sized cooling systems. Ensure the procurement spec includes air intake filtration class and service interval requirements for dusty sites.

Q: What warranty and support options are typical for a D1703 assembly?

A: OEM new assemblies usually come with manufacturer warranties that cover parts and labor for defined hours. Remanufactured units will have shorter warranties. Always require a warranty statement and clarify excluded items in the contract.

Q: Can the D1703 meet emissions requirements in regulated markets?

A: Emissions compliance depends on the specific engine configuration and any aftertreatment installed. Specify the required emissions standard (e.g., EU Stage, EPA Tier) in the procurement documents and confirm certification from the supplier.

Q: What spare parts should be procured with the engine?

A: Typical spares include filters (fuel, oil, air), belts, gaskets, fuel injectors, sensors, and a basic gasket set. Ask the supplier for an OEM-recommended spare kit matched to your operating hours.

Next Steps & Call to Action

Contact us to view product details or request a quote

If you are specifying the Isuzu D1703 Diesel Engine Assembly for your fleet or projects, our specialists can provide detailed technical drawings, compatibility checks, and a tailored procurement package including spare parts and warranty options. Contact our sales team to view the full product datasheet, request a factory acceptance plan, or get a customized quote.

Contact Sales: Email our procurement support or call our technical sales team to schedule a consultation and factory test plan. View the Isuzu D1703 product page or request a quote to start the procurement process.

Authority and References

Trusted sources for further reading

Excavator Engine Replacement: When and How

Where to Buy engine assembly

Hydraulic Pump Noise Diagnosis and Fixes for 2026

Top 5 excavator hydraulic pump Company List and Products Compared

FAQ

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -