jackhuang5919@gmail.com

Compatibility Checklist for Isuzu D1703 in Heavy Machinery

- Compatibility Checklist for Isuzu D1703 in Heavy Machinery

- Product Overview: Isuzu D1703 Diesel Engine | High-Performance Engine Assembly for Heavy Machinery

- Why Compatibility Matters for Engineered Diesel Installations

- Mechanical Fit: Mounts, Dimensions, and Bellhousing

- Power & Torque Matching: Performance and Duty Cycle

- Cooling System Compatibility: Radiator, Flow, and Thermal Management

- Fuel System & Engine Management for Engineered Diesel

- Exhaust & Emissions Compliance

- Electrical & Control Integration

- Lubrication, Oil Grade and Service Intervals

- Accessories, PTOs and Hydraulic Integration

- Serviceability & Parts Availability: Total Cost of Ownership

- Step-by-Step Compatibility Checklist (Practical Workflow)

- Compatibility Reference Table

- Brand and Product Advantages: Why Choose Isuzu D1703 for Heavy Machinery

- Installation Best Practices and Avoidable Mistakes

- FAQ: Common Questions About Isuzu D1703 Compatibility and Integration

- Q: Is the Isuzu D1703 suitable for all excavator sizes?

- Q: Do I need software/calibration changes when swapping in a D1703?

- Q: How do I confirm emissions compliance after an engine swap?

- Q: Are spare parts and filters for the D1703 easy to source?

- Q: What routine checks should be part of preventive maintenance?

- Contact Sales / View Product

- Authoritative References and Resources

Compatibility Checklist for Isuzu D1703 in Heavy Machinery

Product Overview: Isuzu D1703 Diesel Engine | High-Performance Engine Assembly for Heavy Machinery

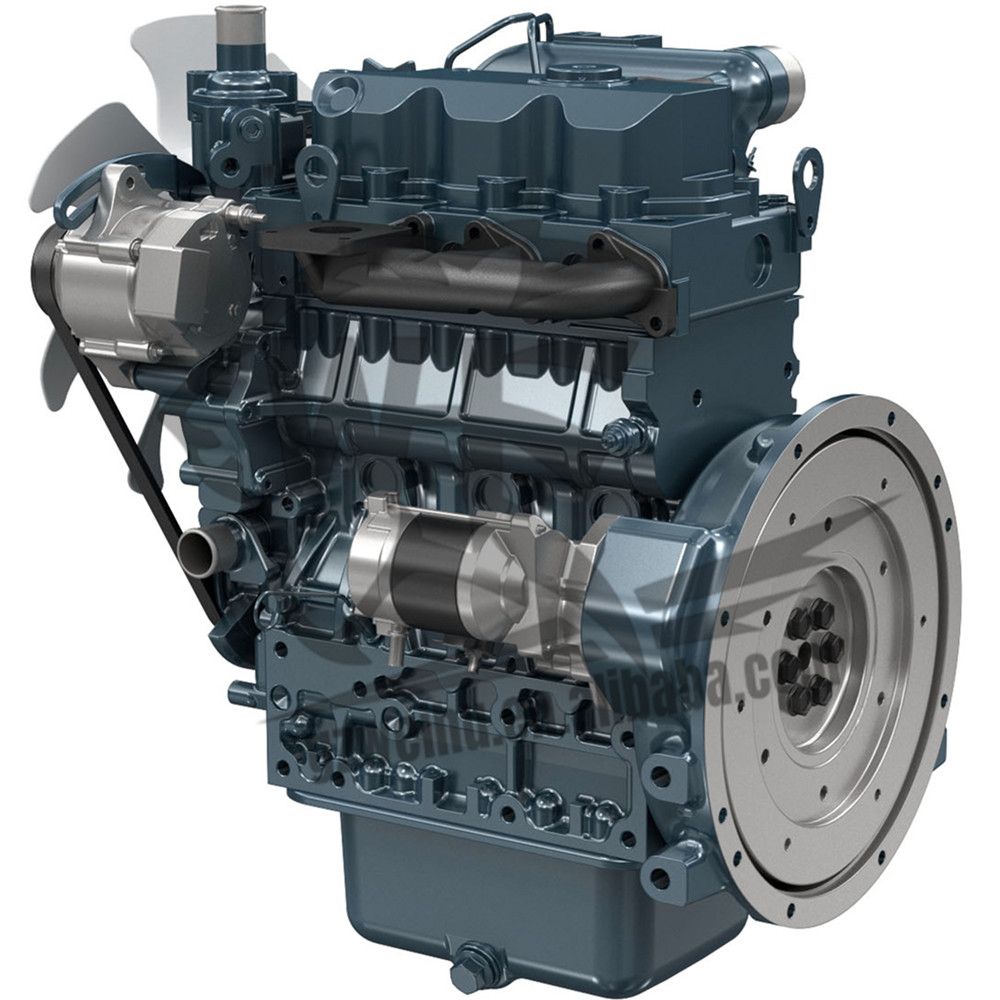

⭐ D1703 Engine – Product Description

The D1703 Engine is a high-performance, durable, and reliable diesel engine designed for heavy-duty machinery, including excavators, construction equipment, and industrial applications. Manufactured by Isuzu, this engine combines cutting-edge technology with exceptional power, fuel efficiency, and longevity, making it the ideal choice for businesses that require consistent and efficient engine performance in demanding environments.

Why Compatibility Matters for Engineered Diesel Installations

Installing an engineered diesel such as the Isuzu D1703 into an existing heavy machine is not just about bolt patterns and hose lengths. Compatibility drives machine performance, fuel economy, emissions compliance, and lifecycle costs. Choosing an engine that does not match the host machine's mechanical, thermal, and control systems can lead to accelerated wear, frequent downtime, and safety risks. This section explains the four high-level compatibility domains you must evaluate before committing to a D1703 swap or new-build integration.

Mechanical Fit: Mounts, Dimensions, and Bellhousing

Mechanical compatibility is the first gate. Confirm that engine mount locations, overall dimensions, and bellhousing/transmission interfaces align with the host chassis. Many heavy machines have limited engine bay space, unique mount geometries, and proprietary bellhousings. Key checks include:

- Physical envelope: length, width, height, and clearance for service access.

- Mounting points: coordinate hole patterns, vibration isolation spec, and torque limits.

- Bellhousing and flywheel compatibility: ensure mating with existing transmission input shaft and starter orientation.

- Accessory placement: alternator, pump drives, PTOs, and mounting brackets should not obstruct cooling or operator access.

Power & Torque Matching: Performance and Duty Cycle

A well-matched powertrain delivers predictable performance and protects drivetrain components. The Isuzu D1703 is an engineered diesel intended for sustained heavy use, but you must verify the following against the machine’s duty cycle:

- Rated power and torque curve: compare the D1703’s usable torque band to the machine’s operational needs (e.g., trenching vs. travel speed).

- Transient response: hydraulic systems often require quick torque bursts; confirm engine load acceptance and governor response time.

- Safety margins: ensure the engine does not routinely run at or above peak continuous rating to preserve life.

Cooling System Compatibility: Radiator, Flow, and Thermal Management

Heat rejection is a common integration failure point. The D1703 will require a cooling system sized for its heat output plus the heat generated by the host machine’s auxiliary systems. Check:

- Radiator capacity and fan drive: flow rate, pressure drop, and fan horsepower are crucial.

- Coolant routing and hose lengths: avoid sharp bends, pressure points, or long runs that increase head loss.

- Oil cooler and charge-air cooler (if applicable): ensure both are sized and positioned to maintain operating temperatures under maximum ambient conditions.

Fuel System & Engine Management for Engineered Diesel

Fuel quality, filtration, and control strategy significantly affect reliability. The D1703 is an engineered diesel system that may include specific injection timing and filtration requirements. Confirm:

- Fuel supply pressure and pump capacity match the D1703 specification.

- Primary and secondary filtration efficiency meets ISO contamination levels recommended by Isuzu.

- Compatibility with any engine control unit (ECU) or governor: wiring harness, CAN protocols, and diagnostic connectors.

Exhaust & Emissions Compliance

Emissions standards influence aftertreatment and exhaust routing. When integrating the D1703 into heavy machinery, validate:

- Exhaust backpressure limits and muffler fitment.

- Presence and space for aftertreatment (DOC/DPF/DEF) if required to meet local regulations.

- Emissions certification applicability: whether the D1703 configuration meets the region’s Tier/Stage standards for the machine’s operating environment.

Electrical & Control Integration

Modern engineered diesel engines rely on precise control. Electrical integration checks include:

- Compatibility of the D1703 ECU with the machine’s harness and sensors (voltage levels, CAN bus baud rates).

- Starter and alternator output capacity relative to the host electrical loads.

- Provision for fault reporting and telematics integration to support preventative maintenance.

Lubrication, Oil Grade and Service Intervals

Longevity hinges on correct lubrication and scheduled service. For the D1703, verify:

- Recommended oil viscosity and API/ACEA specifications and whether they match local climate requirements.

- Oil filter clearance and access for quick changes.

- Simplified service intervals and parts availability to minimize downtime.

Accessories, PTOs and Hydraulic Integration

Excavators and other hydraulic machines demand coordinated PTO and pump drives. Confirm:

- Power take-off (PTO) interface and allowable torque for external pumps.

- Hydraulic pump drive geometry and shaft speed relationship to the engine’s power band.

- Accessory drive belts and pulleys: alignment and tensioning clearance.

Serviceability & Parts Availability: Total Cost of Ownership

Beyond initial fit, ongoing support determines the true value of an engineered diesel engine. When selecting the D1703, evaluate:

- Spare parts distribution in your operating region (filters, gaskets, sensors).

- Technical documentation and repair manuals availability.

- Local authorized service centers or trained technicians for warranty and repairs.

Step-by-Step Compatibility Checklist (Practical Workflow)

Use this checklist as an executable sequence when assessing or planning an installation of an Isuzu D1703 engineered diesel:

- Gather documentation: machine chassis drawings, transmission spec, cooling diagram, and electrical schematics.

- Compare physical envelopes and mounting points; produce CAD overlays if possible.

- Verify flywheel/ bellhousing and starter positions; measure shaft alignments.

- Assess cooling capacity: calculate heat rejection and validate radiator/fan matches.

- Match fuel system pressure and filtration; plan fuel line routing and tank venting.

- Confirm ECU and harness compatibility, identify required adapters or software updates.

- Check emissions and aftertreatment requirements for your operating region.

- Plan service access and parts logistics; finalize warranty and support contracts.

- Build a test protocol: idle-to-full-load ramps, hydraulic function checks, and thermal soak tests.

Compatibility Reference Table

The table below compares key compatibility factors of the Isuzu D1703 against common host-machine requirements. Use it as a decision matrix during evaluation.

| Compatibility Factor | Isuzu D1703 Characteristics (Typical) | What to Check on Host Machine |

|---|---|---|

| Mechanical Envelope | Compact 4-cylinder / 3-cylinder package designed for industrial applications (check specific model drawings) | Clearance, mount points, accessory position, service access |

| Power & Torque Delivery | Smooth torque curve optimized for heavy-duty cycles (engineered diesel tuning) | Match torque band to hydraulic loads and transmission gearing |

| Cooling Demand | Moderate to high heat rejection depending on tuning and application | Radiator capacity, fan drive, charge-air cooling (if turbocharged) |

| Fuel System | Requires clean fuel and filtration; may use ECU-controlled injection | Fuel pump capacity, filtration levels, line routing, and venting |

| Electrical Integration | ECU or governor control; standard diagnostic ports and sensor sets | CAN/ECU compatibility, harness length, starter/alternator capacity |

| Service & Parts | Good global support network from Isuzu where available | Local parts availability, trained technicians, service intervals |

Brand and Product Advantages: Why Choose Isuzu D1703 for Heavy Machinery

When considering an engineered diesel replacement or new engine spec, Isuzu offers several advantages that matter to fleet owners and engineers:

- Proven reliability: decades of diesel engineering validate durability across harsh operating environments.

- Efficiency: optimized combustion and injection strategies yield favorable fuel consumption for duty cycles typical of excavators and construction equipment.

- Aftermarket support: wide service networks and parts distribution in many regions reduce downtime risk.

- Compatibility focus: Isuzu provides technical documentation and OEM-level support to assist integrators with mechanical and electrical mating.

Installation Best Practices and Avoidable Mistakes

Typical installation pitfalls include inadequate cooling capacity, ignoring ECU calibration differences, and omitting proper fuel filtration. Best practices are:

- Perform a detailed mock-up prior to final installation (3D scan or CAD overlay).

- Use OEM-specified consumables (filters, oils, belts) and follow run-in procedures.

- Document wiring changes and label harnesses for future maintenance.

- Conduct a staged commissioning: dry electrical tests, static mechanical checks, and progressive load testing.

FAQ: Common Questions About Isuzu D1703 Compatibility and Integration

Q: Is the Isuzu D1703 suitable for all excavator sizes?

A: The D1703 is designed for a range of heavy-duty industrial applications, but suitability depends on the excavator's weight class, hydraulic demand, and operating profile. Use the checklist above to verify power, torque, and cooling compatibility before deciding.

Q: Do I need software/calibration changes when swapping in a D1703?

A: Often yes. If the host machine relies on engine speed/torque signals or has integrated telematics, the D1703's ECU parameters and CAN messaging may need adaptation. Work with an authorized service provider to adjust maps and ensure fault-exchange compatibility.

Q: How do I confirm emissions compliance after an engine swap?

A: Check local emissions regulations and whether the installed D1703 configuration (including aftertreatment) meets required Tier/Stage levels. Maintain documentation for inspections and regulatory filings.

Q: Are spare parts and filters for the D1703 easy to source?

A: Isuzu maintains a robust global parts network, but availability can vary regionally. Confirm local distributors carry common wear items and consider stocking critical spares for field operations.

Q: What routine checks should be part of preventive maintenance?

A: Include daily visual inspections, fuel/water separator draining, weekly oil level checks, and scheduled filter and coolant changes per Isuzu recommendations. Monitor for abnormal smoke, noise, or temperature trends.

Contact Sales / View Product

Once compatibility is confirmed, decision-makers typically assess real-world output by reviewing performance under load in an Isuzu D1703 engineered diesel review.If you’re evaluating an Isuzu D1703 engineered diesel for your fleet, our technical team can provide dimensional drawings, integration guidance, and a quotation tailored to your machine. Contact us: Contact Sales or view product details: Isuzu D1703 Diesel Engine | High-Performance Engine Assembly for Heavy Machinery.

Authoritative References and Resources

For technical specs, service manuals, and regulatory guidance, consult these authoritative resources:

- Isuzu Engines & Service Documents - Isuzu official sites and technical bulletins (refer to your regional Isuzu distributor for exact D1703 manuals).

- International Emissions Standards - Government or regulatory bodies detailing Tier/Stage emissions requirements (EPA, EU).

- Industry Knowledge Base - Wikipedia: Isuzu (https://en.wikipedia.org/wiki/Isuzu) for company history and diesel engine background.

Note: For model-specific dimensions, torque curves, and calibration files, request the official D1703 product datasheet and maintenance manual from an authorized Isuzu distributor or our sales team to ensure accuracy for your integration project.

Troubleshooting Common Doosan DX65 Pump Issues

Hydraulic Pump Seal and Leak Repair for Excavators: Complete Practical Guide

Selecting the right engine assemblies for heavy excavators

Top Signs Your Excavator Engine Needs Repair

FAQ

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

Do you provide warranties on your products?

Yes, we stand by the quality of our products. Most parts come with a warranty that covers manufacturing defects. Please refer to the specific warranty information provided with your purchase or contact our customer service team for details.

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

Cummins QSB6.7 Diesel Engine – High Power, Durable, Original Industrial Engine

QSB6.7 Engine – Product Description (Detailed English Version)

The Cummins QSB6.7 Diesel Engine is a high-performance 6.7-liter, 6-cylinder powerhouse designed for demanding industrial, construction, and agricultural applications. Built with advanced combustion technology and premium components, the QSB6.7 delivers outstanding power, fuel efficiency, durability, and low emissions—making it one of the most widely used engines in the global equipment market.

Cummins QSL8.9 Diesel Engine – High Power and Reliability for Heavy Equipment

Cummins QSL8.9 Diesel Engine – High Power, High Efficiency, High Reliability

🔧 Product Overview

The Cummins QSL8.9 engine is a powerful 8.9-liter, six-cylinder, turbocharged diesel engine designed for heavy-duty industrial and construction machinery.

With advanced high-pressure common rail fuel injection technology and electronic control systems, the QSL8.9 delivers outstanding performance, fuel efficiency, and durability, making it one of the most trusted engines in its class.

Hydraulic Pump for CAT 349GC | Reliable Performance, Fast Shipping

The CAT 349GC hydraulic pump is engineered to deliver efficient and reliable hydraulic power for Caterpillar 349GC excavators. Manufactured using premium materials and precision engineering, this pump is suitable for OEM replacement or high-quality aftermarket upgrades. It ensures smooth hydraulic flow, durability, and optimal performance even in the most demanding working conditions.

-

✔️ Direct fit for CAT 349GC excavators

-

✔️ OEM and aftermarket options available

-

✔️ High-pressure performance for heavy-duty applications

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for reliability and longevity

-

✔️ Fast global shipping and responsive customer support

- 🚜 Order your CAT 349GC Hydraulic Pump now!

📞 Contact us for bulk pricing, customization, and technical support.

📦 Worldwide shipping available. OEM & aftermarket options.

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -