jackhuang5919@gmail.com

Comparing OEM and Aftermarket Hydraulic Pumps for 336D

- Why Pump Choice Matters for the CAT 336D

- Operational demands and duty cycles

- Impact on efficiency and fuel use

- Downtime and lifecycle costs

- OEM vs Aftermarket: Technical Comparison of Hydraulic Pumps

- Design, materials and manufacturing tolerances

- Performance specifications: flow, pressure and efficiency

- Testing, standards and quality control

- Making the Right Selection: Maintenance, Installation, and Cost Considerations

- Installation and direct-fit considerations

- Maintenance, contamination control and fluid compatibility

- Warranty, support and total cost of ownership

- Real-world Performance, Troubleshooting, and When to Replace

- Signs of hydraulic pump failure

- Field testing and diagnostic checks

- When to choose OEM vs aftermarket

- FAQ — Common Questions about 336D Hydraulic Pumps

- Q: Can I replace my 336D hydraulic pump with an aftermarket unit?

- Q: How long should a hydraulic pump last on a 336D?

- Q: What maintenance steps extend pump life?

- Q: Are aftermarket pumps less efficient than OEM pumps?

- Q: What tests should I request from a pump supplier?

This article compares OEM and aftermarket hydraulic pumps for the CAT 336D excavator, focusing on performance, durability, fitment, serviceability and lifecycle costs to help fleet managers, technicians and owners make the best choice for heavy-duty operations. Whether you run a single machine or manage a fleet, understanding hydraulic pump construction, testing standards, contamination control and warranty differences can reduce downtime and operating costs while improving on-site productivity.

Product spotlight:

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

Why Pump Choice Matters for the CAT 336D

Operational demands and duty cycles

The CAT 336D is a heavy-duty excavator used for digging, loading, and lifting in construction and mining. Its hydraulic pump is the heart of the hydraulic system — supplying flow and pressure to actuators, swing motors, and attachments. A properly matched hydraulic pump ensures consistent flow rates, stable pressure under load, and predictable machine response. Choosing between an OEM hydraulic pump and an aftermarket replacement directly affects uptime, fuel efficiency, and operator confidence.

Impact on efficiency and fuel use

Hydraulic pump efficiency determines how much engine power is converted into useful hydraulic work versus being lost as heat. Higher volumetric and mechanical efficiency reduces engine load and fuel consumption, especially under variable load cycles common with the 336D. Precise tolerances in pump components, matched swash plates, and correct porting reduce internal leakage and improve overall hydraulic system efficiency.

Downtime and lifecycle costs

Downtime on a 336D can quickly become costly. Total cost of ownership (TCO) includes the pump price, installation labor, downtime cost, maintenance, and the expected lifetime of the pump under your duty cycle. An OEM pump often commands a High Quality price but may reduce risk and installation time. High-quality aftermarket options can offer strong TCO improvements if they meet or exceed testing and warranty criteria.

OEM vs Aftermarket: Technical Comparison of Hydraulic Pumps

Design, materials and manufacturing tolerances

OEM pumps are engineered to the original machine specifications and typically use materials and machining tolerances validated by the OEM. Aftermarket suppliers range from budget to High Quality; top-tier aftermarket pumps use equivalent materials, re-engineered seals, and improved coatings. Critical components to inspect include gear tooth profiles (for gear pumps), piston surface finish (for axial piston pumps), and bearing quality, all of which affect wear life and noise.

Performance specifications: flow, pressure and efficiency

Key performance parameters for any excavator hydraulic pump are rated flow (L/min or GPM), maximum operating pressure (bar or psi), and volumetric/mechanical efficiency. When comparing options for the 336D, ensure the replacement pump meets or exceeds the original flow and pressure ratings. A mismatch can cause sluggish operation or premature wear. Performance curves from reputable suppliers or third-party test reports are useful for side-by-side evaluation.

Testing, standards and quality control

Independent testing and adherence to standards are crucial. Look for manufacturers that test pumps for volumetric efficiency, pressure spike tolerance, noise, and thermal performance. Industry standards such as those published by ISO and guidelines from organizations like the Hydraulic Institute provide frameworks for contamination control and test methods. Manufacturer test reports or third-party validation increase confidence in aftermarket options.

| Criteria | OEM Hydraulic Pump | Aftermarket Hydraulic Pump (High Quality) | Aftermarket Hydraulic Pump (Budget) |

|---|---|---|---|

| Fitment | Guaranteed direct fit to CAT 336D | Direct fit or drop-in with verification | May require minor modifications |

| Materials & Tolerances | OEM-specified alloys & tight tolerances | Comparable materials; high-quality machining | Lower-grade materials; variable tolerances |

| Testing & Certification | OEM QA, factory test reports | Independent testing & spec sheets | Limited or no testing data |

| Warranty & Support | OEM warranty; dealer support | Strong warranty; direct supplier support | Short warranty, limited support |

| Cost | Highest initial cost | Mid-range; often 20–50% less | Lowest upfront cost |

| Availability | May require dealer lead time | Often faster delivery via aftermarket suppliers | Widely available |

| Long-term Reliability | High when maintained properly | Comparable if High Quality quality | Higher risk of early failure |

Sources on hydraulic pump fundamentals include technical references such as Wikipedia's hydraulic pump overview and manufacturer papers from leading suppliers like Parker Hannifin. These resources explain pump types (gear, vane, axial piston) and performance factors relevant to the 336D.

Making the Right Selection: Maintenance, Installation, and Cost Considerations

Installation and direct-fit considerations

For the CAT 336D, a direct-fit pump reduces installation time and alignment issues. OEM pumps are designed for bolt-for-bolt replacement. High-quality aftermarket pumps marketed specifically for the 336D will typically be drop-in replacements; always verify shaft splines, mounting flange dimensions, and port locations. Improper fitment risks misalignment, increased vibration, and premature seal failure.

Maintenance, contamination control and fluid compatibility

Contamination is a leading cause of hydraulic pump failure. Adhere to recommended hydraulic fluid cleanliness levels (ISO 4406 particle codes are commonly used; see ISO standards for reference). Regular filtration, correct viscosity fluid, timely oil analysis, and scheduled filter changes extend life regardless of pump origin. Consider upgrading filtration or adding return-line filtration when installing a replacement pump — this is especially important when fitting a new pump into an older system with accumulated wear particles.

Warranty, support and total cost of ownership

Warranty policies differ: OEM warranties often include dealer network support and extended parts history, while aftermarket warranties vary by supplier. When calculating TCO, factor in the warranty length, warranty claim process, expected lifetime under your duty cycle, and availability of local technical support. A lower upfront cost can be offset by increased downtime or more frequent rebuilds — align your choice with operational risk tolerance.

Real-world Performance, Troubleshooting, and When to Replace

Signs of hydraulic pump failure

Common indicators include reduced lifting speed, erratic machine response, excessive noise (whining or knocking), increasing hydraulic oil temperature, and visible leaks. Pressure tests, flow measurements at known RPM, and oil analysis help confirm pump health. A failing pump may allow internal leakage that reduces system efficiency long before a catastrophic failure occurs.

Field testing and diagnostic checks

Perform baseline measurements: measure maximum system pressure, flow at known engine RPM, and pressure drop across filters. Compare to factory specifications. Use oil analysis to check for metal particles (bearing or gear wear) and contamination levels. If installing a replacement, verify no abnormal vibration, no metal debris in returned oil, and stable temperatures during a controlled load test.

When to choose OEM vs aftermarket

Use this practical guidance:- Choose OEM if you require guaranteed direct-fit, prefer manufacturer-backed diagnostics and support, or operate in extreme duty cycles where risk tolerance is low.- Choose High Quality aftermarket when reputable suppliers provide independent testing, comparable materials, and better lead times or pricing, especially for fleets seeking to reduce TCO without sacrificing reliability.- Reserve budget aftermarket pumps for non-critical machines, short-term fixes, or where rapid replacement is the main priority, but plan for closer monitoring.

FAQ — Common Questions about 336D Hydraulic Pumps

Q: Can I replace my 336D hydraulic pump with an aftermarket unit?

A: Yes. Many high-quality aftermarket pumps are designed as direct-fit replacements for the CAT 336D. Verify specifications — flow, pressure rating, shaft and mounting compatibility — and ask for test reports or certifications before purchase.

Q: How long should a hydraulic pump last on a 336D?

A: Lifespan depends on duty cycle, maintenance, contamination control, and operating environment. With proper filtration and regular maintenance, a hydraulic pump can last several thousand operating hours. OEM or High Quality aftermarket pumps with proper care can deliver similar lifespans.

Q: What maintenance steps extend pump life?

A: Maintain proper hydraulic fluid cleanliness (refer to ISO cleanliness standards), perform regular filter changes, monitor oil temperature, conduct periodic oil analysis, and ensure correct hydraulic fluid viscosity and additive package.

Q: Are aftermarket pumps less efficient than OEM pumps?

A: Not necessarily. High Quality aftermarket pumps can match or sometimes exceed OEM efficiency if they use high-quality components and rigorous testing. Always compare efficiency curves and test data rather than assuming lower performance based on brand alone.

Q: What tests should I request from a pump supplier?

A: Ask for volumetric efficiency tests, pressure and flow curves, noise level data, and endurance testing results. Independent third-party testing or factory test certificates add credibility. Reference technical resources such as the Hydraulic Institute for recommended practices.

For technical whitepapers and selection guidance, see authoritative resources like the hydraulic pump overview on Wikipedia, industry suppliers (e.g., Parker Hannifin) and standards organizations (ISO).

If you’re ready to inspect product options, view the 336D replacement: 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement. For a quote, compatibility check, or technical consultation, contact our support team and we’ll help you select an OEM or High Quality aftermarket hydraulic pump tailored to your duty cycle and budget.

Contact us: Request a quote or technical support — or view full product details and ordering information on the product page above.

Maintenance Tips to Extend the Lifespan of Your Hydraulic Pump

Maintenance schedules for ZAX870-5G 6WG1 engine assemblies

Lead Time & Inventory Strategies for Hydraulic Pump Sourcing

The B2B Buyer’s Guide to excavator engine

FAQ

Do you provide installation services for your parts?

While we do not offer installation services directly, we can recommend qualified professionals or resources to assist you with the installation of our parts. Our customer support team can provide guidance on finding local service providers.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

How can I place an order?

You can place an order through our user-friendly online platform or by contacting our sales team directly. Simply browse our catalog, select the parts you need, and follow the checkout process to complete your order.

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

Do you offer bulk purchasing options?

Yes, we offer competitive pricing for bulk orders. If you are interested in purchasing large quantities of parts, please contact our sales team to discuss your requirements and receive a customized quote.

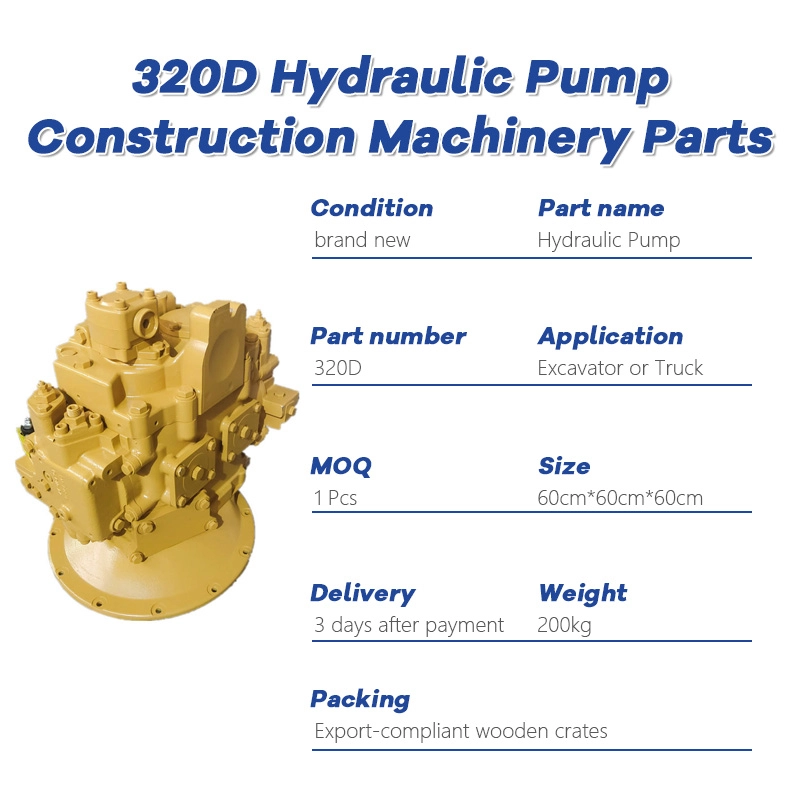

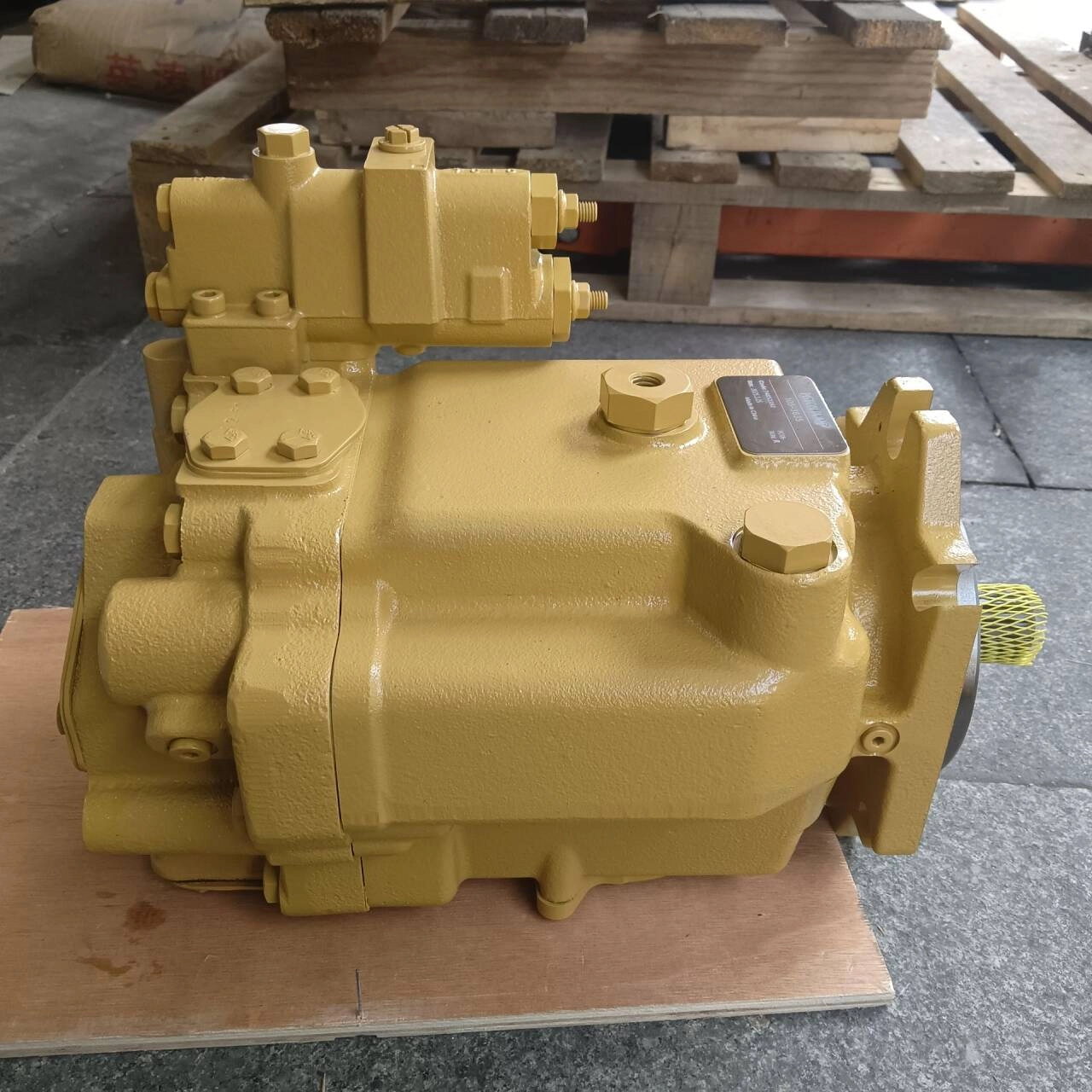

CAT 320D SBS120 Hydraulic Pump for Excavator | High Quality Replacement

This high-performance SBS120 hydraulic pump is specially designed for the CAT 320D excavator. Built with premium materials and precision manufacturing, it ensures reliable power delivery and long-lasting performance in tough construction environments. Ideal as an OEM replacement or aftermarket solution, this pump supports your hydraulic system with smooth, efficient operation.

-

Fits: Caterpillar 320D

-

Model: SBS120

-

Application: Excavator main hydraulic pump

-

Condition: New / Aftermarket available

-

Warranty: 6-12 months (optional)

-

Worldwide shipping available

-

CAT 980H Hydraulic Pump | Heavy-Duty Loader Replacement Part

The CAT 980H and 980G hydraulic pumps are engineered to provide optimal hydraulic power and durability for Caterpillar loaders. Built with premium materials and precision manufacturing, these pumps are ideal for OEM replacements and high-quality aftermarket upgrades. They ensure smooth hydraulic operation and reliable performance in demanding construction environments.

-

✔️ Direct fit for CAT 980H and 980G loaders

-

✔️ Available in OEM and aftermarket versions

-

✔️ High-pressure, heavy-duty hydraulic performance

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for durability and efficiency

-

✔️ Fast global shipping and excellent customer support

- 🛒 Order your CAT 980H & 980G Hydraulic Pump now!

📞 Contact us for bulk orders, technical support, or custom requests.

📦 Fast worldwide shipping | OEM & aftermarket options available -

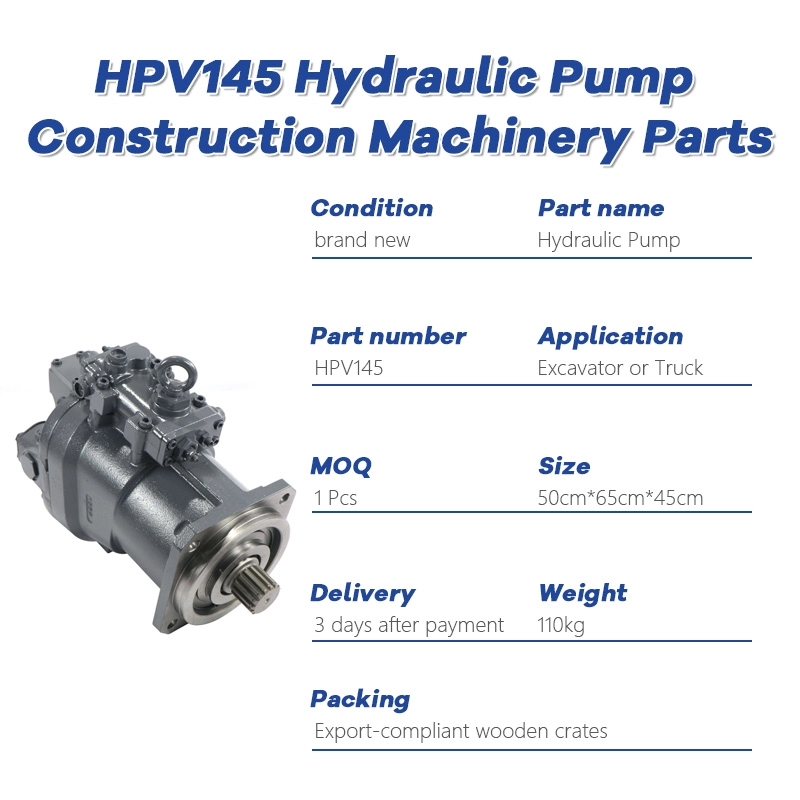

HPV145 Hydraulic Pump (Direct Injection) | Excavator Main Pump Replacement

The HPV145 single pump with direct injection technology is designed for excavators and heavy-duty machinery requiring precise hydraulic control and efficient power delivery. Combining advanced direct injection control with durable axial piston pump construction, this model ensures high performance, long service life, and reliable operation. Available in OEM and aftermarket versions, it is ideal for replacement or system upgrades.

-

✔️ Direct injection electronic control for precise hydraulic output

-

✔️ Suitable for excavators and various heavy machinery

-

✔️ High-pressure axial piston single pump design

-

✔️ OEM and aftermarket options for flexibility and cost-effectiveness

-

✔️ Robust materials and quality seals for long-term durability

-

✔️ Fast worldwide shipping and comprehensive technical support

- 🛒 Order Your HPV145 Direct Injection Single Pump Today – Precision, Durability & Performance

📞 Contact Us for pricing, availability, and technical support

🌍 Fast Global Shipping | OEM & Aftermarket | Secure Payment Options -

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -