jackhuang5919@gmail.com

Hydraulic Pump Buying Guide for 336D Excavator Owners

- Understanding Why the Right Hydraulic Pump Matters

- What a hydraulic pump does in a 336D excavator

- Signs you need a replacement or upgrade

- Why choose a pump built for the 336D

- Choosing Between OEM and Aftermarket Hydraulic Pumps

- OEM vs High-quality aftermarket: pros and cons

- Key decision factors: compatibility, warranty, price, availability

- Comparison table: OEM vs Aftermarket

- Technical Checklist Before Buying

- Confirm model fit and part numbers

- Flow and pressure requirements

- Mounting, shaft and coupling details

- Installation, Testing and Maintenance Best Practices

- Professional installation vs in-house replacement

- Flushing, filtration and oil selection

- Break-in, testing and monitoring

- Diagnostics, Troubleshooting and Extending Pump Life

- Common failure modes and diagnostic steps

- Preventive maintenance checklist

- When to rebuild vs replace

- Sources and Further Reading

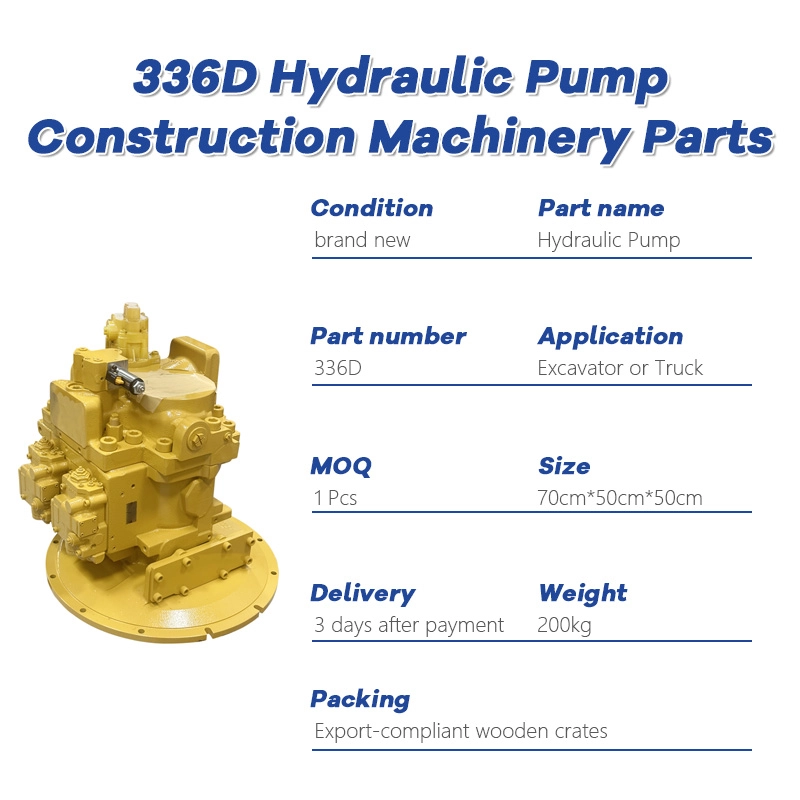

- 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement — Product Overview

- FAQ — Common Questions from 336D Owners

- Q: How do I know if I need the exact CAT part number?

- Q: Can I use any hydraulic oil with the new pump?

- Q: Is an aftermarket pump as reliable as OEM?

- Q: How long does a hydraulic pump replacement typically take?

- Q: What preventative steps reduce future pump failures?

Summary for : This guide helps CAT 336D excavator owners quickly find the right hydraulic pump solution by combining on-machine compatibility checks, performance and durability considerations, and sourcing recommendations. It highlights OEM and high-quality aftermarket options for the 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement and provides actionable troubleshooting, installation, and maintenance steps that are optimized for global searches and local procurement needs.

Understanding Why the Right Hydraulic Pump Matters

What a hydraulic pump does in a 336D excavator

The hydraulic pump is the heart of a tracked excavator's hydraulic system. It converts mechanical power from the engine into hydraulic flow and pressure, powering the boom, arm, bucket, swing, and travel circuits. A correctly specified hydraulic pump ensures efficient flow, stable pressure under load, and reliable control response during heavy-duty operations.

Signs you need a replacement or upgrade

Common symptoms of a failing hydraulic pump include reduced digging power, sluggish boom/arm response, unusual noises (whine, groan), overheating of the hydraulic oil, and visible leaks at the pump flange or shaft seal. Early diagnosis prevents collateral damage to valves, cylinders, and the hydraulic motor system.

Why choose a pump built for the 336D

The 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement is designed for direct fit and heavy-duty performance. Choosing a unit specifically built for Caterpillar 336D minimizes installation time and alignment issues, and reduces the risk of premature failure that can occur with generic pumps. This product is available in OEM and high-quality aftermarket versions to match owner priorities for budget, warranty, and lifecycle cost.

Choosing Between OEM and Aftermarket Hydraulic Pumps

OEM vs High-quality aftermarket: pros and cons

OEM pumps come from the original equipment manufacturer and usually match the machine's original specifications exactly, often backed by manufacturer warranty and support. High-quality aftermarket pumps offer competitive pricing and sometimes enhanced features or faster lead times, but quality varies by supplier. For CAT 336D owners, selecting a reputable aftermarket brand that tests for performance and durability is essential to meet heavy-duty demands.

Key decision factors: compatibility, warranty, price, availability

When comparing options, focus on these factors:

- Compatibility: direct-fit models for CAT 336D reduce modification needs.

- Warranty and support: better warranties indicate confidence in durability.

- Price vs lifecycle cost: a cheaper pump with poor durability can cost more long-term.

- Availability and lead time: onsite downtime drives many buyers to choose readily available aftermarket units.

Comparison table: OEM vs Aftermarket

| Criteria | OEM (CAT) | High-quality Aftermarket |

|---|---|---|

| Compatibility | Guaranteed direct fit for 336D | Direct-fit options available; verify part number |

| Warranty | Manufacturer warranty and dealer support | Varies (select vendors offer strong warranties) |

| Price | Higher initial cost | Typically lower, competitive pricing |

| Lead time | May be longer due to dealer schedules | Often faster delivery for stocked aftermarket units |

| Quality consistency | High, factory-tested | High if vendor is reputable; varies otherwise |

Technical Checklist Before Buying

Confirm model fit and part numbers

Always check the engine and pump part numbers against your machine's serial number and service manual. CAT part numbers and cross-references can be found through the official Caterpillar parts resources. If you are replacing a pump, record the serial number stamped on the pump housing and compare it with the seller's compatibility list.

Flow and pressure requirements

Match the hydraulic pump's maximum flow (L/min or gpm) and operating pressure (bar or psi) with the machine's hydraulic circuit requirements. Over- or undersized pumps can impair performance or overload components. If you are unsure of exact figures, consult your 336D service manual or an authorized dealer for safe specifications.

Mounting, shaft and coupling details

Verify shaft type (splined or keyed), flange bolt pattern, and coupling style. For a direct-fit 336D pump, these dimensions should match without adapter plates. Incorrect shaft geometry or mounting offset increases wear and can cause rapid failure.

Installation, Testing and Maintenance Best Practices

Professional installation vs in-house replacement

Installing a hydraulic pump involves precise alignment, torqueing, hydraulic line routing, and filling/bleeding the system. For most owners, using trained technicians or an authorized service provider reduces the risk of installation errors. If you possess in-house hydraulic experience and tools, follow the manufacturer's torque specs and clean-room practices during pump installation.

Flushing, filtration and oil selection

Before installing a replacement pump, flush the hydraulic circuit to remove contaminants that can quickly destroy a new pump. Replace filters and confirm cleanliness. Use hydraulic oil meeting the viscosity and specification recommended by Caterpillar; improper fluids shorten pump life and degrade efficiency. For guidance on hydraulic system cleanliness and filtration standards, consult the Hydraulic Institute and ISO cleanliness recommendations.

Break-in, testing and monitoring

After installation, follow a staged break-in procedure: run at low loads to allow seals to seat and bearings to stabilize, then gradually bring the system to full operational pressures. Monitor temperatures, pressures, and oil contamination levels for the first 50–100 operating hours. Installing pressure gauges and flow meters during testing helps verify pump performance under load.

Diagnostics, Troubleshooting and Extending Pump Life

Common failure modes and diagnostic steps

Frequent failure causes include contamination, cavitation, overpressure, misalignment, and internal wear. Diagnostic steps:

- Check hydraulic oil level and condition.

- Inspect suction lines and strainers for restriction (cavitation indicator).

- Listen for unusual noises under load (bearing or vane issues).

- Measure system pressure and compare to expected values.

Preventive maintenance checklist

To extend pump life and reduce downtime, implement these routines:

- Keep hydraulic oil clean and at correct levels; sample oil regularly.

- Replace suction and return filters per interval or earlier if contamination rises.

- Inspect hoses, fittings, and seals for wear and leaks.

- Monitor operating temperatures and address cooling issues promptly.

When to rebuild vs replace

Rebuilding a pump can be cost-effective if housing and drive components are in good condition and replacements use matched-grade parts and precise machining. However, extensive internal wear, hub damage, or unavailable core parts often justify a complete replacement with a tested unit, especially in high-hour machines like working 336D excavators.

Sources and Further Reading

For authoritative references on hydraulic systems and best practices, consult:

- Hydraulic pump — Wikipedia

- Caterpillar — official site (parts & service)

- Hydraulic Institute — standards and guidance

- SAE International — engineering standards and papers

336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement — Product Overview

This CAT 336D hydraulic pump is built for power, durability, and optimal performance. It is designed to fit Caterpillar 336D excavators and is available in both OEM and high-quality aftermarket versions. Whether you're replacing a damaged pump or upgrading your hydraulic system, this part ensures long-lasting and reliable operation in demanding construction environments.

- ✔️ Direct fit for CAT 336D excavators

- ✔️ Available in OEM or High Quality aftermarket

- ✔️ High-pressure performance for heavy-duty operations

- ✔️ Smooth and efficient hydraulic flow

- ✔️ Rigorously tested for quality and durability

- ✔️ Global shipping and responsive support

FAQ — Common Questions from 336D Owners

Q: How do I know if I need the exact CAT part number?

A: Always verify the part number printed on your existing pump or in the machine’s service manual. Direct-fit parts eliminate guesswork and reduce installation time. If you cannot locate the part number, provide the machine serial number to your supplier so they can confirm compatibility.

Q: Can I use any hydraulic oil with the new pump?

A: No. Use hydraulic oil that meets Caterpillar’s viscosity and cleanliness recommendations for the 336D. Incorrect oil viscosity or contamination increases wear and reduces pump efficiency. Consult your manual or dealer for the exact spec.

Q: Is an aftermarket pump as reliable as OEM?

A: High-quality aftermarket pumps can be as reliable as OEM when sourced from reputable manufacturers who provide performance testing and warranty. Check for vendor quality certifications, test reports, and customer reviews before purchasing.

Q: How long does a hydraulic pump replacement typically take?

A: For a trained technician with parts and tools on hand, replacement and system bleed/testing commonly take one to two working days. More complex jobs (e.g., access limitations or additional component replacement) can extend that time.

Q: What preventative steps reduce future pump failures?

A: Maintain oil cleanliness, replace filters proactively, check for suction restrictions, avoid overheating, and schedule regular inspections. Early attention to warning signs dramatically extends pump life.

If you need help selecting the correct 336D hydraulic pump, comparing OEM vs aftermarket options, or arranging fast shipping and installation, contact our support team or view the product page:

View 336D Excavator Hydraulic Pump | Heavy Duty CAT Replacement | Contact Customer Service

Top 10 excavator parts Manufacturers and Supplier Brands

Compliance & Testing Standards for Hydraulic Pump Procurement

Integration Guide: Installing SY550 6WG1 into Existing Fleets

Total Cost of Ownership: Engineered Diesel Isuzu D1703

FAQ

What is your shipping policy?

We offer a variety of shipping options to meet your needs. Orders are typically processed within [insert processing time] days, and delivery times may vary based on your location. We will provide you with tracking information once your order has shipped.

Are your parts compatible with all excavator brands?

Weihuparts strives to offer parts compatible with a wide range of excavator brands and models. However, we recommend checking the product specifications or consulting with our team to ensure compatibility with your specific excavator.

Can I return or exchange parts if I change my mind?

Yes, we accept returns and exchanges within [insert return period, e.g., 30 days] of purchase. The items must be unused and in their original packaging. Please contact our customer service team to initiate a return or exchange.

How do I know which parts I need for my excavator?

If you are unsure which parts are needed, our knowledgeable customer support team can assist you. You can provide us with your excavator model and any relevant details, and we will help you identify the correct parts.

What types of excavator parts do you offer?

Weihuparts provides a comprehensive range of excavator parts, including but not limited to buckets, hydraulic components, undercarriage parts, and engine components. Our goal is to be your one-stop solution for all excavator needs.

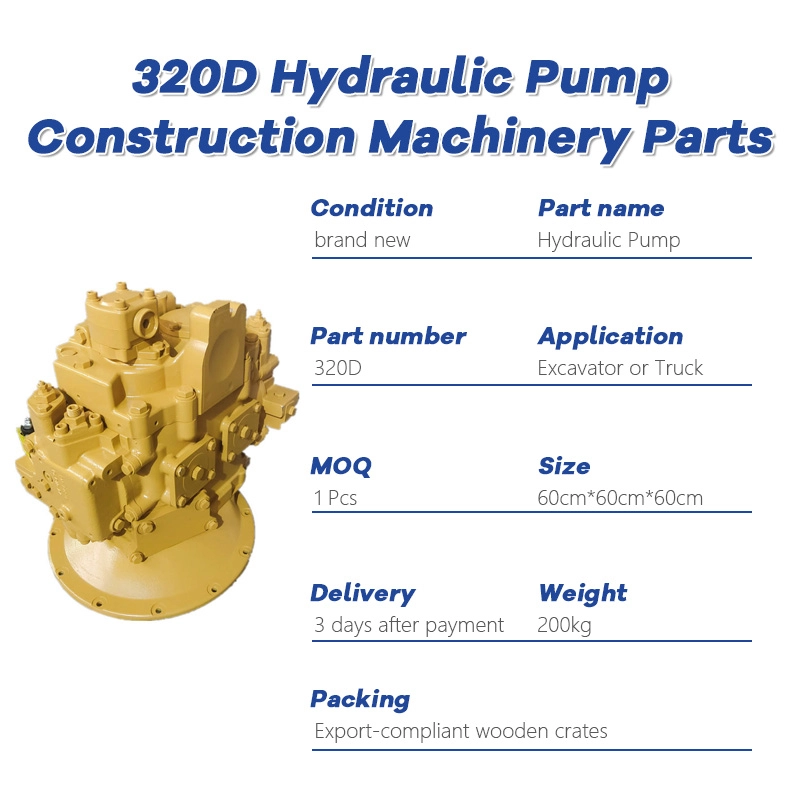

CAT 320D SBS120 Hydraulic Pump for Excavator | High Quality Replacement

This high-performance SBS120 hydraulic pump is specially designed for the CAT 320D excavator. Built with premium materials and precision manufacturing, it ensures reliable power delivery and long-lasting performance in tough construction environments. Ideal as an OEM replacement or aftermarket solution, this pump supports your hydraulic system with smooth, efficient operation.

-

Fits: Caterpillar 320D

-

Model: SBS120

-

Application: Excavator main hydraulic pump

-

Condition: New / Aftermarket available

-

Warranty: 6-12 months (optional)

-

Worldwide shipping available

-

CAT 980H Hydraulic Pump | Heavy-Duty Loader Replacement Part

The CAT 980H and 980G hydraulic pumps are engineered to provide optimal hydraulic power and durability for Caterpillar loaders. Built with premium materials and precision manufacturing, these pumps are ideal for OEM replacements and high-quality aftermarket upgrades. They ensure smooth hydraulic operation and reliable performance in demanding construction environments.

-

✔️ Direct fit for CAT 980H and 980G loaders

-

✔️ Available in OEM and aftermarket versions

-

✔️ High-pressure, heavy-duty hydraulic performance

-

✔️ Manufactured with high-strength alloys and quality seals

-

✔️ Tested for durability and efficiency

-

✔️ Fast global shipping and excellent customer support

- 🛒 Order your CAT 980H & 980G Hydraulic Pump now!

📞 Contact us for bulk orders, technical support, or custom requests.

📦 Fast worldwide shipping | OEM & aftermarket options available -

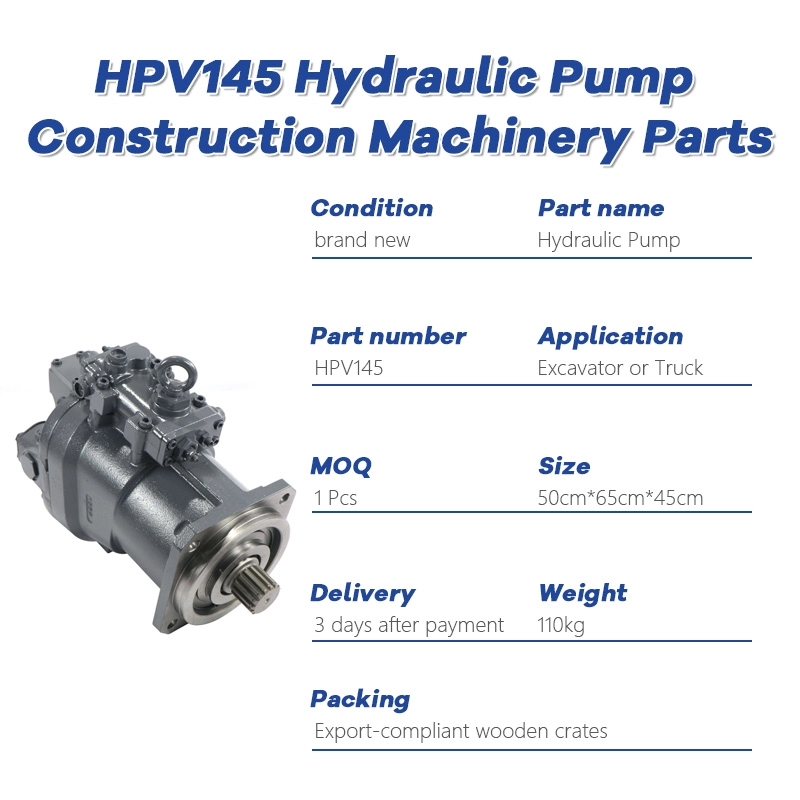

HPV145 Hydraulic Pump (Direct Injection) | Excavator Main Pump Replacement

The HPV145 single pump with direct injection technology is designed for excavators and heavy-duty machinery requiring precise hydraulic control and efficient power delivery. Combining advanced direct injection control with durable axial piston pump construction, this model ensures high performance, long service life, and reliable operation. Available in OEM and aftermarket versions, it is ideal for replacement or system upgrades.

-

✔️ Direct injection electronic control for precise hydraulic output

-

✔️ Suitable for excavators and various heavy machinery

-

✔️ High-pressure axial piston single pump design

-

✔️ OEM and aftermarket options for flexibility and cost-effectiveness

-

✔️ Robust materials and quality seals for long-term durability

-

✔️ Fast worldwide shipping and comprehensive technical support

- 🛒 Order Your HPV145 Direct Injection Single Pump Today – Precision, Durability & Performance

📞 Contact Us for pricing, availability, and technical support

🌍 Fast Global Shipping | OEM & Aftermarket | Secure Payment Options -

Caterpillar 345GC Hydraulic Pump | Heavy-Duty Excavator Part

The CAT 345GC hydraulic pump is engineered to deliver powerful and reliable hydraulic flow for Caterpillar 345GC excavators. Designed with high-quality materials and precision manufacturing, this pump is ideal for both OEM replacement and aftermarket upgrades. Built to endure demanding job sites, it ensures excellent performance, reduced downtime, and longer service life.

-

✔️ Direct-fit for CAT 345GC excavators

-

✔️ Available in OEM or high-quality aftermarket versions

-

✔️ Smooth, efficient hydraulic operation

-

✔️ Built with high-strength alloy and premium seals

-

✔️ Tested for pressure, flow, and durability

-

✔️ Fast shipping & global logistics supported

- 🚜 Order Now – Upgrade your CAT 345GC excavator with a high-performance hydraulic pump.

📞 Contact Us for bulk pricing, customization, or technical details.

📦 Worldwide Shipping | 🧰 OEM & Aftermarket Available | 💬 24/7 Customer Support -